Advantages and applications of hand-held fiber laser welding machine?

The handheld fiber laser welding machine is a new generation of laser welding equipment, which belongs to non-contact welding. The operation process does not require pressure. Its working principle is to directly irradiate a high-energy intensity laser beam on the surface of the material through the interaction of the laser and the material, The material is melted inside, and then cooled and crystallized to form a weld.

China Welding Machine 1000W Handheld Fiber Laser factory , overturning the working mode of the traditional laser welding machine, has the advantages of simple operation, beautiful welding seam, fast welding speed, and no consumables. It can be used for welding thin stainless steel plates, iron plates, galvanized plates and other metal materials. It can perfectly replace traditional argon arc welding, stainless steel plate, iron plate, aluminum plate and other metal materials welding.

Advantages of handheld laser welding machine

1. Flexible operation

Easy operation, no need experience can do a good job,The welding range is wide, and the handheld welding head is equipped with 5m-10M original optical fiber, which overcomes the limitation of the workbench space, and can be welded outdoors and long-distance welding;

2. High efficiency

Speed is faster than the traditional welding speed by more than two times, It is convenient and flexible to use. Hand-held laser welding is equipped with movable pulleys, which is comfortable to hold and can adjust the station at any time. It is free and flexible, suitable for various working environment scenarios.

Wholesales 1000W Handheld Fiber Laser Welding Machine

3. High quality, multiple welding methods

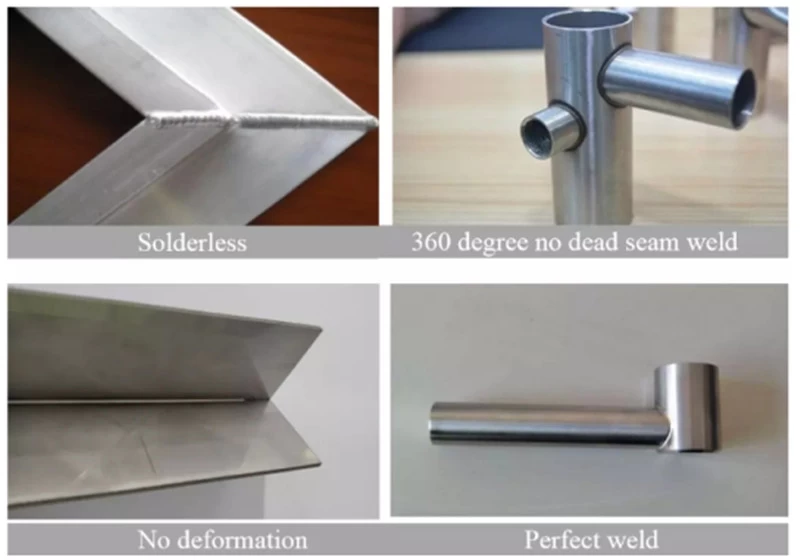

Welding at any angle can be realized: overlap welding, butt welding, vertical welding, flat fillet welding, internal fillet welding, external fillet welding, etc., and can weld various complex welded workpieces and large workpieces with irregular shapes. The heat-affected area is small during welding, which will not cause work deformation, blackening, and traces on the back. Moreover, the welding depth is large, the welding is firm, and the melting is sufficient. Smooth and beautiful welding seam,without subsequent grinding, saving time and cost.

4. Low cost

80% to 90% power savings, processing costs are reduced by 30%, welding without consumables. In most people's impression, the welding operation is "left-handed goggles, right-handed welding wire". But with the handheld laser welding machine, the welding can be easily completed, which reduces the material cost in production and processing.

China Handheld Welding Manufacture - Welding Samples of stainless steel

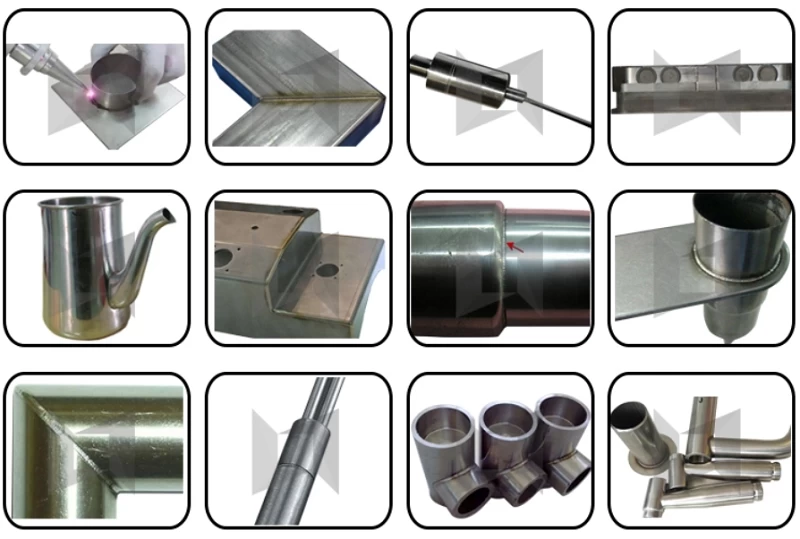

Application field of handheld laser welding machine

Mainly for the fixed position of large and medium-sized sheet metal, cabinets, chassis, aluminum alloy door and window frames, stainless steel wash basins and other large workpieces, such as inner right angles, outer right angles, and flat welds. The heat-affected area during welding is small, the deformation is small, and the welding depth is small. Large, strong welding. It is widely used in kitchen and bathroom industry, home appliance industry, advertising industry, mold industry, stainless steel products industry, stainless steel engineering industry, doors and windows industry, handicraft industry, household goods industry, furniture industry, auto parts industry, etc.