Application and advantages of carbon dioxide laser

Carbon dioxide is the most important greenhouse gas today. It has a great impact on the warming of the earth and the environment, and it is also one of the biggest challenges facing mankind.

However, based on the special physical and chemical properties of carbon dioxide, it has a wide range of uses in the national economy and has penetrated almost all walks of life, such as.

1. Utilizing the characteristics of carbon dioxide being larger than air and not supporting combustion, many fire extinguishers produce carbon dioxide to extinguish fires.

2. Carbon dioxide can be used for sterilization and sterilization, and it can also be used to preserve food when filled in a sealed tank.

3. Solid carbon dioxide (or dry ice) can be used for artificial rain, stage smoke effect, food industry, etc.

4. Carbon dioxide can also be injected into the beverage to make the beverage with bubbles and increase the taste when drinking.

CO2 Laser Marking Machine Price China

Today I talk about the application of carbon dioxide in the industrial field. How to use carbon dioxide to output laser?

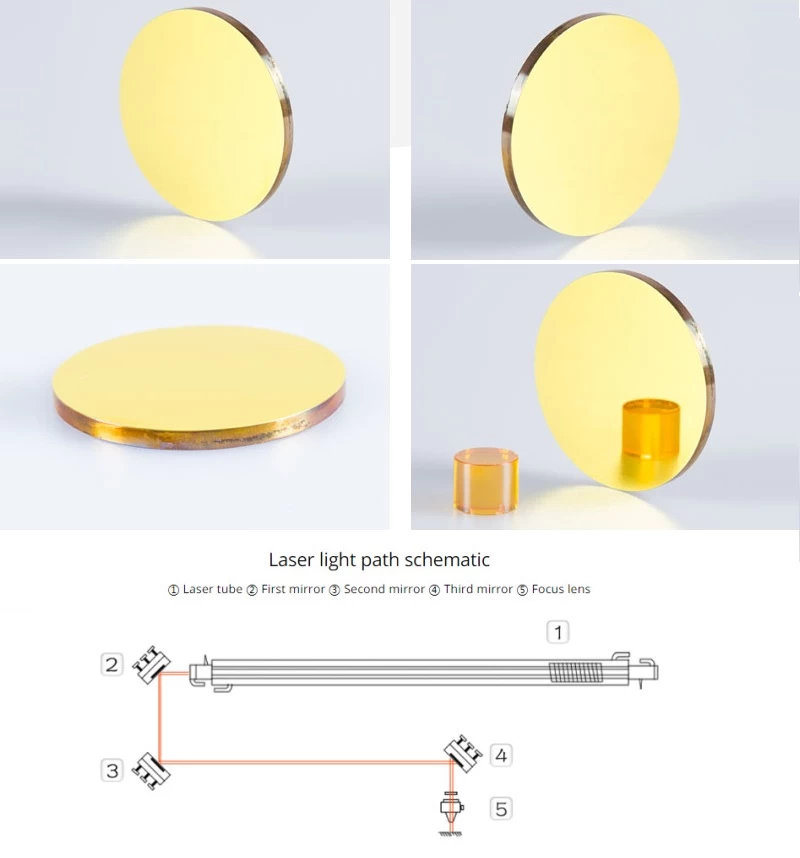

Carbon dioxide laser refers to the use of carbon dioxide, nitrogen, and helium as the working gas (carbon dioxide accounts for 10-20%), and high-voltage direct current is applied under appropriate conditions to make carbon dioxide molecules in an excited state to generate photons, which are placed in the resonant cavity The internal oscillation is amplified until a certain power laser is transmitted through the output window mirror to form a usable laser beam.

Carbon dioxide laser is a kind of laser with higher continuous output power. It has been developed earlier and commercial products are relatively mature. It is widely used in materials processing, medical treatment, military weapons, environmental measurement and other fields. At the same time, it also has the advantages of high output beam optical quality, good coherence, narrow line width, stable work, etc. It is often used as a cutting machine, engraving machine or welding machine in the industrial field.

Application: CO2 laser has a laser wavelength of 10.6um, which has a low absorption coefficient for metals. It is generally suitable for cutting non-metallic materials and welding metal materials. It can be widely used in welding applications in aviation, electronic instruments, machinery, automobiles and other fields.

CO2 Cutting Machine Parts Manufacturer China

CO2 laser is a relatively important gas laser. This is because it has some prominent advantages:

1. It has higher power and higher energy conversion efficiency. Generally, a closed-tube CO2 laser can have a continuous output power of several tens of watts, which far exceeds other gas lasers. At the same time, the energy conversion efficiency of CO2 lasers can reach 30-40%, which also exceeds that of general gas lasers.

2. It utilizes the transition between the vibration-rotational energy levels of the CO2 molecule, and has a relatively rich spectrum.

3. Its output band is just the atmospheric window, that is, the atmospheric transmittance to this wavelength is relatively high.

4. It has good directivity, monochromaticity and frequency stability, and low gas density.

With its high performance, high reliability and low cost, carbon dioxide lasers are ideal for laser marking, engraving and cutting systems.