Did you choose the right nozzle for laser cutting?

With the popularization of laser cutting technology in the field of industrial manufacturing, the quality of laser cutting has increasingly profoundly affected the productivity and benefits of the majority of equipment application customers. Therefore, the pursuit of higher quality cutting quality has attracted more and more attention from many equipment application customers.

In the laser cutting process, the factors that affect the cutting quality and performance include laser beam quality, laser power, cutting speed, workpiece thickness, material type, etc. In addition, cutting head nozzle design, air flow control, etc. are also important influencing factors.

Laser cutting nozzle Suppliers

The nozzle of the cutting head is installed at the front end of the processing head, which helps to control the auxiliary gas and protect the focusing lens. During the cutting process, the workpiece and the nozzle are kept at a stable distance to prevent splashes from rebounding during cutting.

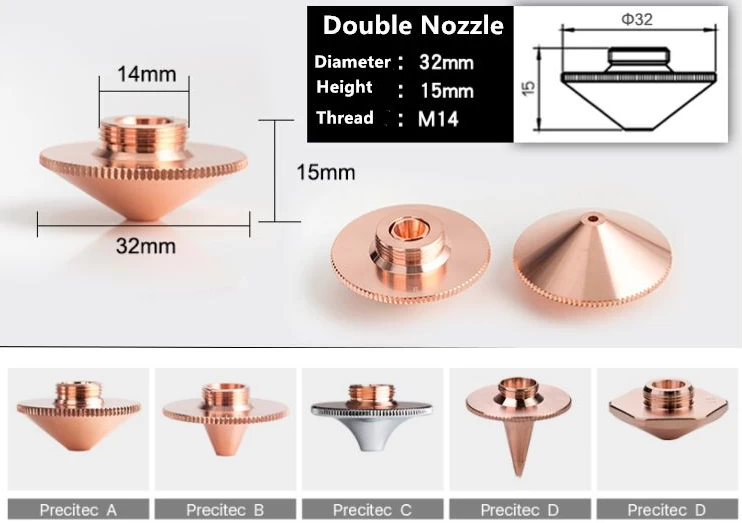

Nozzle type:

Generally, laser cutting nozzles are divided into single and double layers. Single layer nozzles are used for melting and cutting, that is, nitrogen is used as auxiliary gas, usually used for cutting stainless steel, aluminum alloy, brass, etc.; double layer nozzles are generally used for oxidation cutting, that is, use Oxygen is used as an auxiliary gas, usually used for cutting carbon steel.

Nozzle size selection:

The diameter of the nozzle determines the shape of the gas flow entering the incision, the gas diffusion area, and the gas flow rate, which affects the removal of melt and the stability of cutting. The air flow entering the incision is large, the speed is fast, and the position of the workpiece in the air flow is appropriate, the stronger the ability of spraying to remove the molten material.

The user selects the nozzle size according to the laser power used and the thickness of the metal sheet to be cut. Theoretically, the thicker the sheet, the larger the nozzle should be used, the larger the proportional valve setting pressure, the larger the flow, and the pressure can be ensured to cut a normal section effect.

Fiber laser cutting nozzle manufacturer China Carmanhaas We provides Laser Ceramics for Fiber Cutting Head the following types of nozzles

Type A:

28mm (OEM Precitec P0571-1051-00001)

Outside Diameter: 28/24.5mm Thickness: 12mm

Type B:

28mm(OEM Precitec P0571-260-00001)

Outside Diameter: 28/24.5mm Thickness: 12mm

Type C:

32mm(OEM Raytools BT240/BM109)

Outside Diameter: 32/28.5mm Thickness: 12mm

Product Features:

Imported Ceramics, effective insulation, long life

High quality special alloy, good conductivity, high sensitivity

Smooth lines, high insulation