Laser cleaning-green environmental protection, precise control

galvo scanner wholesales china

Laser cleaning is developed based on the principle of interaction between laser and material. Compared with traditional cleaning methods, it has the advantages of green, non-contact, precise control, real-time monitoring feedback, and no damage to the substrate. It is suitable for automobile manufacturing and molds. Cleaning, semiconductor wafer cleaning, precision parts processing and manufacturing, military equipment cleaning, building exterior wall cleaning, cultural relics protection, circuit board cleaning and other fields. It is considered to be a reliable and effective solution to replace traditional cleaning methods.

China customized Galvo Laser Head Suppliers

There are four main laser cleaning methods:

①Laser dry cleaning method, which uses pulsed laser direct radiation to decontaminate;

②Laser + liquid film method, that is, first deposit a layer of liquid film on the surface of the substrate, and then use laser radiation to decontaminate;

③Laser + inert gas method, that is, while the laser is irradiated, an inert gas is blown to the surface of the substrate. When the dirt is peeled from the surface, the gas will be blown off the surface immediately to avoid re-contamination and oxidation of the surface;

④ After using laser to loosen the dirt, clean it with non-corrosive chemical method.

The most commonly used are the first 3 methods. The fourth method is only seen in the cleaning of stone cultural relics.

Optics lens for laser cleaning gun manufacturers

Internationally, laser cleaning technology has been applied to stone materials for more than ten years. In my country, laser cleaning of stone materials started relatively late. Since the investment in laser equipment is still relatively expensive, generalized application still has certain difficulties. However, laser cleaning technology has the incomparable advantages of traditional cleaning methods. With the continuous improvement of technology and the mass production of equipment, laser cleaning technology will definitely play an important role in the cleaning industry of stone materials.

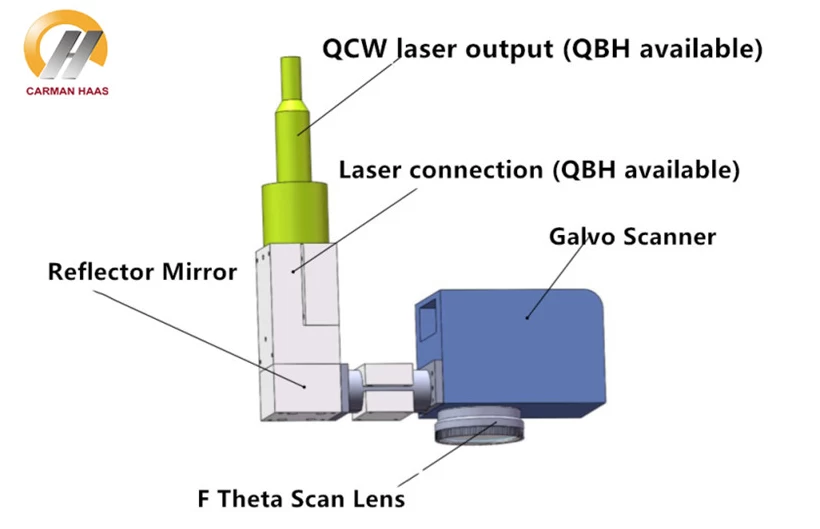

Carmanhaas could offer complete laser cleaning optical lens and system solution. Including QBH Module, Galvo Scanner, F-theta Scan lenses and Control System. We are focus on high end industrial laser application offer.