The function and selection method of the nozzle of the laser cutting machine

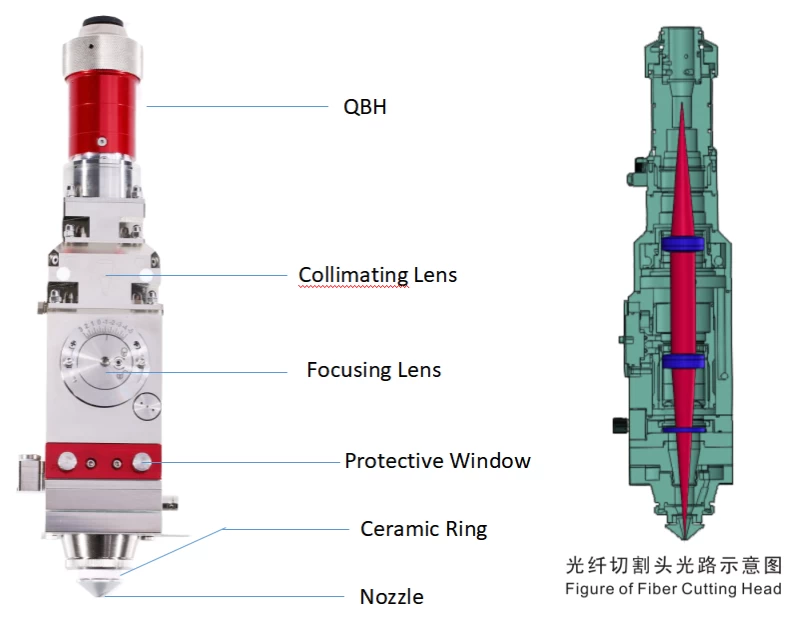

Laser cutting is currently recognized as one of the metal processing methods with high efficiency, high quality and high precision. There are many factors affecting laser cutting, and nozzle is one of them. Nozzle also called copper nozzle, is a very common consumable on laser cutting machines, and it is also a very important part in laser cutting. It is located at the bottom of the laser head. Both the laser beam and the auxiliary gas act on the cutting material through the nozzle, so it is very close to the workpiece. The focused laser and high-pressure airflow are shot through the nozzle, so it plays a very critical role in the cutting process.

China Fiber laser cutting head nozzle manufacturer

The nozzle of the laser cutting machine can assist the rapid ejection of the gas, which can effectively prevent the debris such as molten stains from rebounding upward, thereby protecting the focusing mirror. At the same time, it can control the area and size of the gas diffusion, which will affect the cutting of the laser cutting machine quality.

Choosing the right nozzle when cutting various materials can make processing easier. How to choose the right nozzle correctly?

1. The size of the nozzle: according to the thickness of the metal sheet cut by the user, the size of the nozzle is selected. The aperture of the nozzle controls the flow of gas and the shape of the gas field, which is very important to the quality of the cut. Generally, when a laser cutting machine is used to cut a thin plate below 3mm, it is recommended to use a nozzle with a diameter of 1mm, and a nozzle with a diameter of 1.5mm is recommended for a thickness of more than 3mm. When cutting metal plates with a diameter of 10mm or more, a nozzle with a diameter of 2mm or more is generally selected.

2. Nozzle material: a good nozzle, the material must have high conductivity and good thermal conductivity. Generally, the nozzle made of red copper is better than the one made of brass, which can ensure a good capacitive signal.

3. The processing accuracy of the nozzle: a good laser head nozzle should have a concentricity of 0.03mm, and a nozzle with a size below 1.0mm should have a concentricity of 0.02mm. The high-precision concentric nozzle can not only reduce the early debugging in the processing process, but also effectively prevent the high-energy laser from hitting the inner wall of the laser head, thereby avoiding damage to the laser head.

4. Nozzle surface finish and anti-oxidation treatment: smooth surface and good anti-oxidation treatment can effectively reduce the adhesion of molten material during the cutting process and prolong the service life of the nozzle.

CARMAN HAAS Laser Technology (Suzhou) Co,Ltd. Laser cutting head nozzle Suppliers reminds that when the nozzle is deformed or there is molten stain on the nozzle, it will affect the cutting effect. Therefore, the nozzle should be placed carefully to avoid bumps or deformation, and the nozzle should be cleaned in time when it is stained with molten stains.