What are the advantages of SLS 3D printing nylon materials?

Nylon is one of the most important 3D printing materials in the 3D printing market. Nylon is a synthetic polymer that is abrasion resistant, tough, strong and heat resistant. These properties make nylon ideal for a variety of 3D printing applications.

Selective Laser Sintering (SLS) utilizes an infrared laser to sinter powder. First spread a layer of powder material with a powder coating roller, heat it to a temperature just below the sintering point of the powder by the constant temperature facility in the printing equipment, and then irradiate the powder layer with a laser beam to make the irradiated powder temperature Raised above the melting point, sintered and bonded to the formed part below. When a layer is sintered, the printing platform drops by one layer thickness, and the powder spreading system spreads new powder material for the printing platform, and then controls the laser beam to irradiate again for sintering the print job of the object.(Additive Manufacturing Factory China)

More than 60% of 3D printed nylon powder materials are printed using the SLS process, and nylon 11 (PA11) and nylon 12 (PA12) are the two most commonly used nylon materials. PA11 has better UV and impact resistance, while PA12 has higher strength and stiffness. There are also various reinforced composite materials, such as glass fiber, carbon fiber reinforced nylon materials, and their mechanical properties will be better, just like the modification of plastic materials.

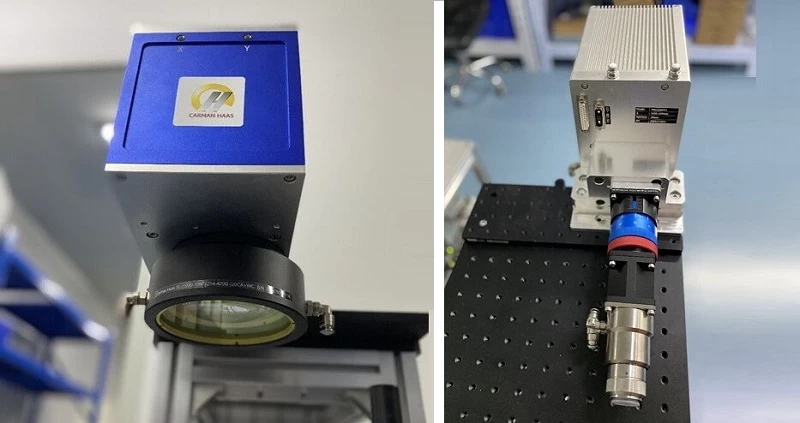

China SLS Optical System Manufacturer

So what are the advantages of 3D printing nylon materials?

1. Nylon printed parts are somewhat grainy, unsupported, and require little post-processing.

2. Nylon has high rigidity and flexibility. Your part will be flexible when you are printing thin products, and rigid when printing thicker walls. This is ideal for parts such as living hinges with rigid parts and flexible joints.

3. Nylon 3D printing can be used to make moving and interlocking parts. This eliminates the need to assemble individual printed parts and enables faster production of highly complex objects.

4. Suitable for prototyping and functional verification parts, such as gears and tools, nylon can be reinforced with carbon fiber or glass fiber, resulting in lightweight components with excellent mechanical properties.