What is the difference between silicon and molybdenum reflectors mirror? How should choose?

The laser mirror is an important component in the laser light transmission system. It is mainly used in the optical path of the laser cutting machine and the laser engraving machine to reflect the laser light. In the CO2 laser light path, the mirror and the focusing mirror cooperate to form a complete light path, which makes the design of the laser machine more space-saving, reduces the laser loss as much as possible, and preserves the working power of the laser to the greatest extent.

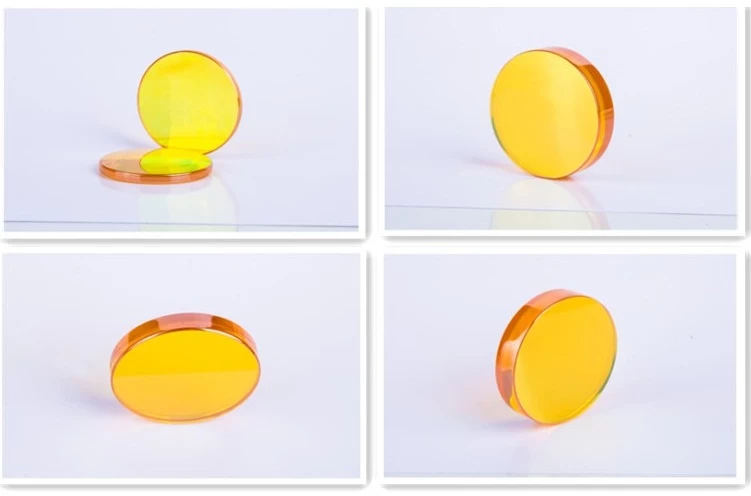

The mirrors generally use molybdenum and silicon as the substrate. We CARMAN HAAS Laser Technology (Suzhou) Co, Ltd. China Reflector Manufacturer produces two types of laser mirrors, one is silicon mirror and the other is molybdenum mirror.

So what is the difference between silicon reflective lenses and molybdenum reflective lenses?

These two types of reflective lenses have different costs, different processes, different prices, and different use effects:

The molybdenum metal mirror is directly polished into a mirror surface from metal molybdenum, and the surface has no coating layer. The process is simple, the production is easy, scrub resistance, and long life. Molybdenum has high surface strength, high melting point, stable chemical properties, high temperature resistance and corrosion resistance. Molybdenum mirrors can work in harsh environments, and the applicable power is below 100W. However, molybdenum and oxygen in the air are prone to oxidation, which reduces the reflectivity and needs to be polished with sandpaper.

Silicon mirrors are currently the most used mirrors and have good optical thermal properties. The material of the silicon reflective lens is silicon, which cannot be used after the silicon is polished. It needs to be coated with a layer of gold film. Because gold is expensive, the cost and price of the silicon reflective lens are high. It has the advantages of high reflectivity, light weight, scratch resistance, strong oxidation resistance and durability. Can withstand higher power 60~300W. The use conditions of silicon reflective lenses are stricter than those of molybdenum reflective lenses, and regular fine cleaning and maintenance are required.