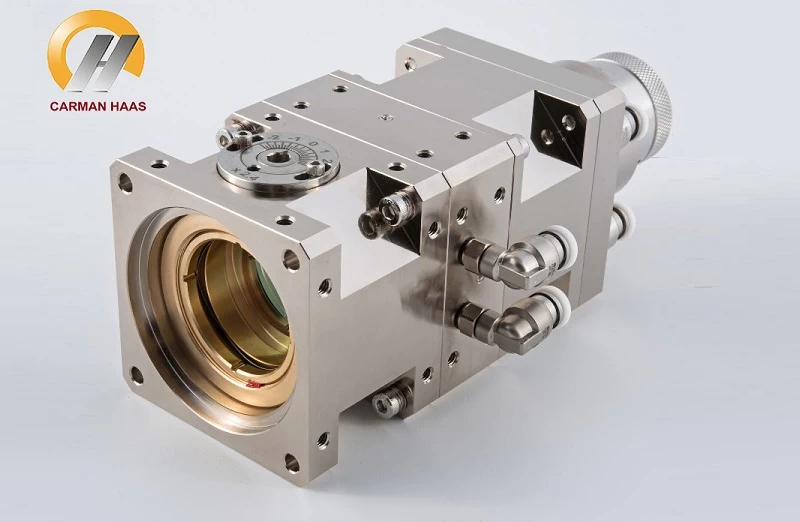

What is the laser QBH, what should I do if the QBH output head fails?

QBH optical Modul supplier china

During the use of the equipment, it is inevitable that the equipment will have various problems. The equipment does not send out the situation that the laser receiving end cannot receive the beam. When it is determined that the laser transmitting end does not send the laser beam, the possible reason is: laser QBH The contact of the output head is not in good contact with the contact of the cutting head.

Solution: turn off the laser, check the laser QBH output head and cutting head, and reinstall.

QBH optical Module price china

Troubleshooting steps for laser cutting machine alarm

During the operation of the laser cutting machine, it has reached a very extreme position. If there is an alarm, please follow these steps to check:

1. Whether the laser cutting machine and the computer are properly grounded.

2. Whether the coordinate value at this moment has exceeded the numerical range limited by the laser cutting machine software.

3. Check whether the size of the drawing you designed exceeds the processing range.

4. Check whether the connection line between the motor shaft and the lead screw is loose. If it is loose, tighten the screw.