Why are more and more industries using laser cleaning?

There are various traditional cleaning methods, such as manual rust removal, mechanical rust removal, chemical treatment, etc. In recent years, the requirements of environmental protection regulations have become more and more strict, and people's awareness of environmental protection and safety has been increasing. Today, the types of chemicals that can be used in industrial production cleaning will become less and less. The emerging laser cleaning technology can solve the problems that cannot be solved by traditional cleaning methods.

So which industries is laser cleaning suitable for, and what is the difference between it and traditional cleaning?

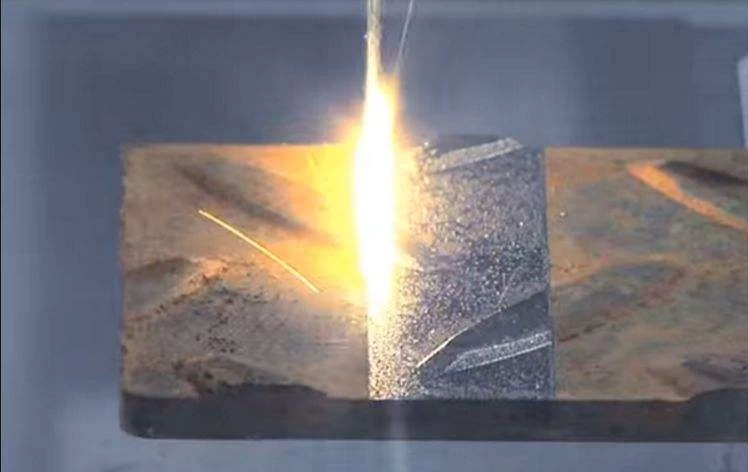

Laser cleaning can be used not only to clean organic pollutants, but also to clean inorganic substances, including metal rust, metal particles, dust, etc. It is widely used in metal or glass surface coating removal, and various oxides quickly remove paint, rust, oil stains, welds and other narrow space metal surface cleaning. It is suitable for military industries such as automobiles, medical equipment, rail transit, molds, aerospace, 3C electronics, steel manufacturing, ships, various steel, iron, aluminum materials and so on.

Laser cleaning has the characteristics of no grinding, non-contact, no thermal effect and suitable for objects of various materials, and is considered to be the most reliable and effective solution.

Manual rust removal is the simplest method, mainly using hammer, chisel, spatula, wire brush, emery cloth, grinding wheel and other tools to manually knock, shovel, scrape, brush and other operations to remove rust. Manual pound removal is labor-intensive, low productivity, and incomplete rust removal. It is only suitable for steel with a small rust removal area and a light rust degree.

Machine rust removal generally uses three types of steel rust removal machines, sandblasting equipment and shot blasting.

Rebar rust remover is the most commonly used mechanical rust removal method at present, but rebar rust remover is only suitable for rust removal of rebar raw materials. Sandblasting and rust removal can effectively remove impurities on the metal surface, such as oxide skin, old rust, etc. However, sandblasting equipment will cause pollution to the environment, and its use is not recommended. Shot blasting is a relatively advanced mechanical treatment method for rust removal of hull steel, which has less pollution to the environment. However, shot blasting is only suitable for indoor operations, and is not suitable for large and complex steel structures.

We Carmanhaas China Laser cleaning equipment on sales supplier offer professional laser cleaning system. Commonly used optical solutions: the laser beam scans the working surface through the galvanometer system and the scan lens to clean the entire working surface. can be easily automated to maximize productivity, and provides the guaranteed repeatability demanded by an increasing number of quality standards.