- Browse Categories

- CO2 Laser Cutting

- Fiber Laser Cutting

- Laser Marking & Engraving

- Fiber Laser Welding

- Marking & Welding Machine

- Additive Manufacturing System

- Laser Etching System

- Ultra-fast Laser Processing

- Laser Cleaning System

- Subscribe

-

Get email updates on new products

- Certifications

-

- Laser Marking & Welding Machine

- Contact Us

-

Suzhou Carman Haas Laser Technology Co., Ltd

Address: No 155, West Road Suhong, Suzhou Industrial Park, Suzhou City, Jiangsu , P.R. China

Tel: +86-18211675110

Fax: +86-512-67678768

E-mail:wangxin@carmanhaas.com

https://www.carmanhaaslaser.com Contact Now

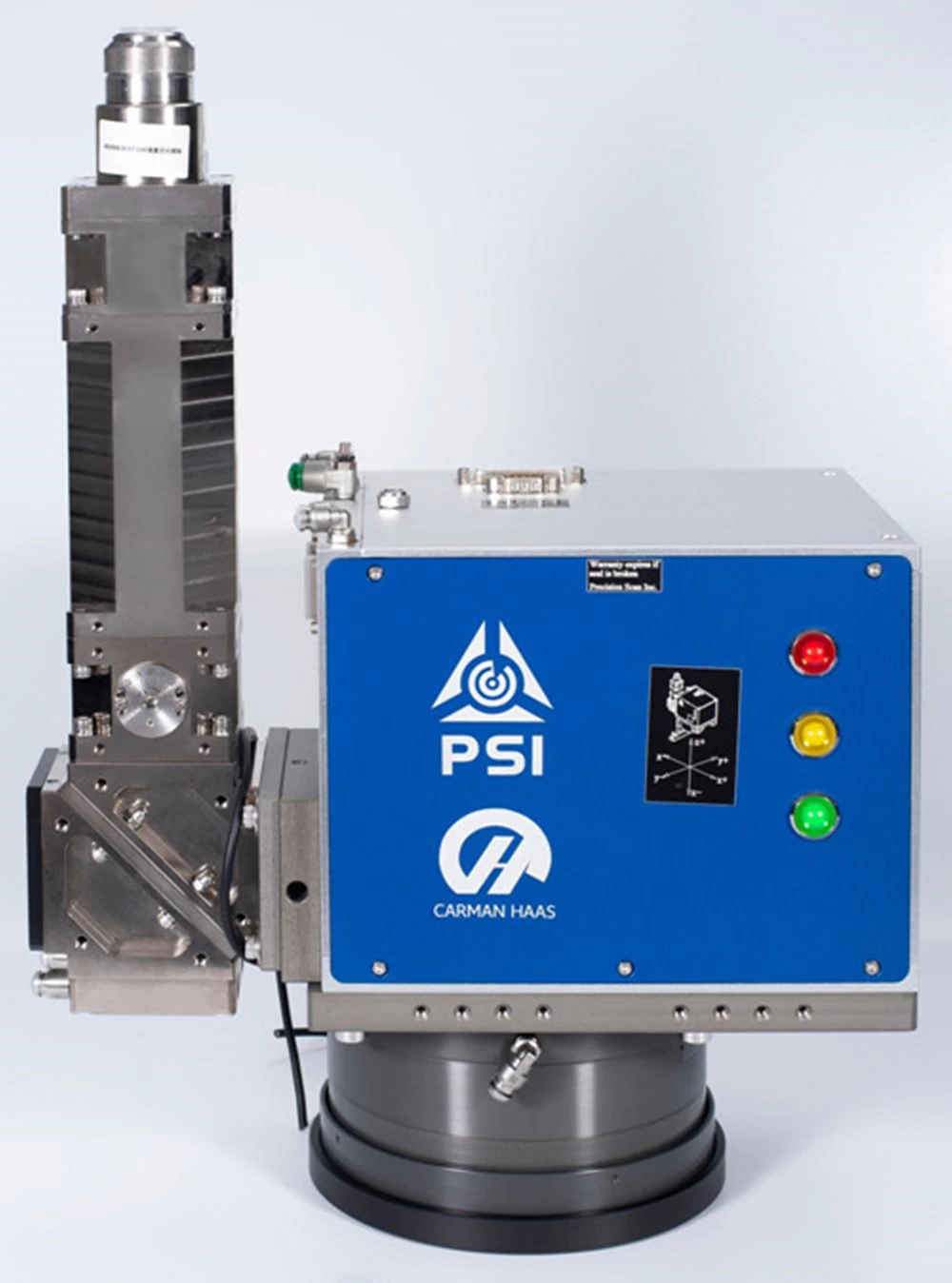

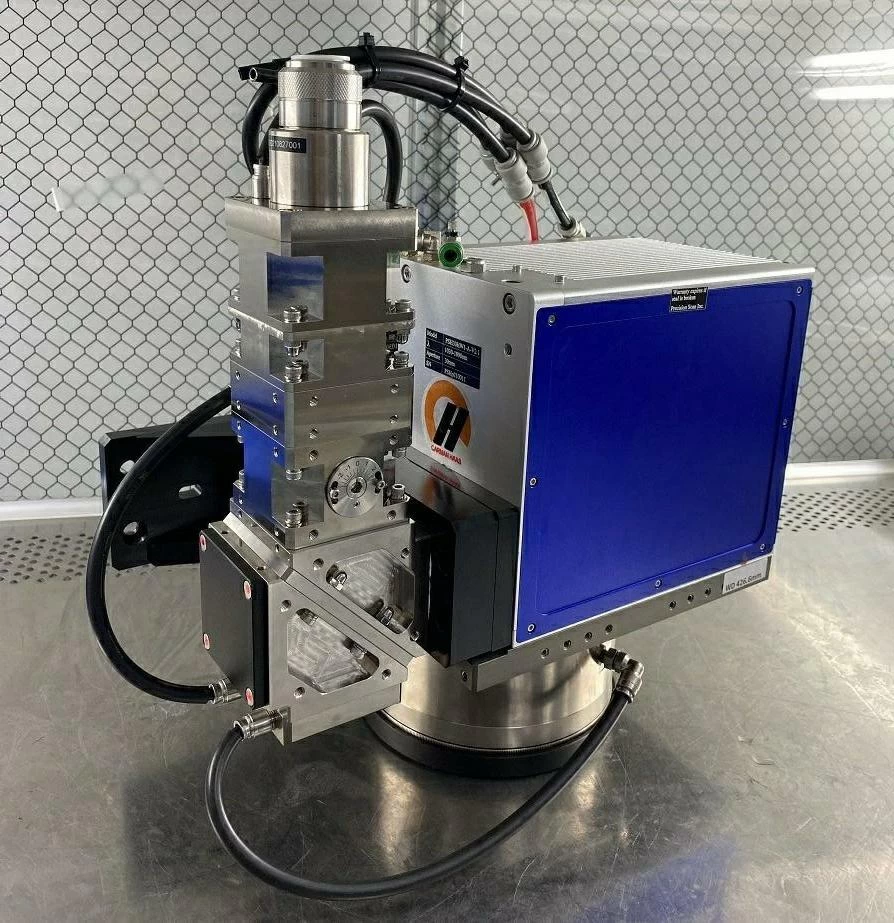

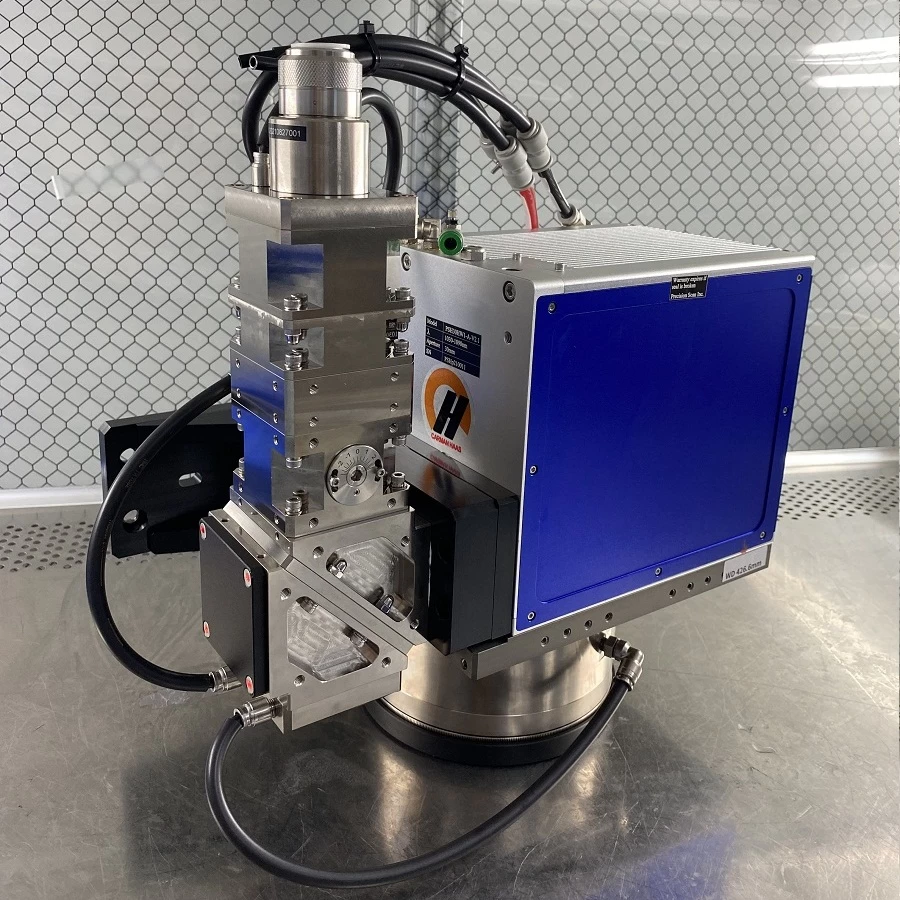

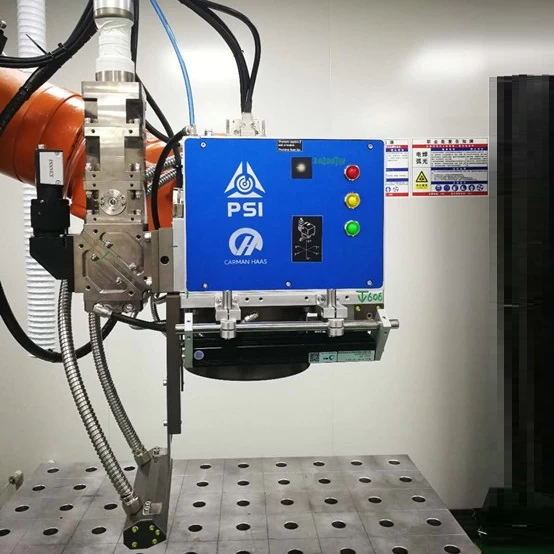

Power Battery Galvo Head Laser Welding Manufacturer China

- Wavelength: 1030-1090nm

- Laser Power: 4000W/6000W

- Laser Source: QBH

- Application: Power Battery Laser Welding

- Brand Name: CARMAN HAAS

- Place of Origin: Jiangsu, China (Mainland)

- Delivery time: within 1 week after receiving payment

Typically, power battery is a new clean energy and currently a research hotspot across the world. It is a kind of storage battery providing the power source for such vehicles as an electric car, electric train, electric bicycle and golf cart. It has been applied to a wide range of industries and become part of people’s lives. (Power battery Manufacturer China)

Power battery is mainly made up of anode material, cathode material (carbon material), separator, electrolyte, battery shell, etc. As the core component of new energy vehicles, it directly determines the vehicle performance. Laser welding is a kind of manufacturing process to weld these raw materials into the battery cell, battery pack, etc., which is very critical for the whole production process of the power battery.

Comparison of Common Welding Methods of Power Battery

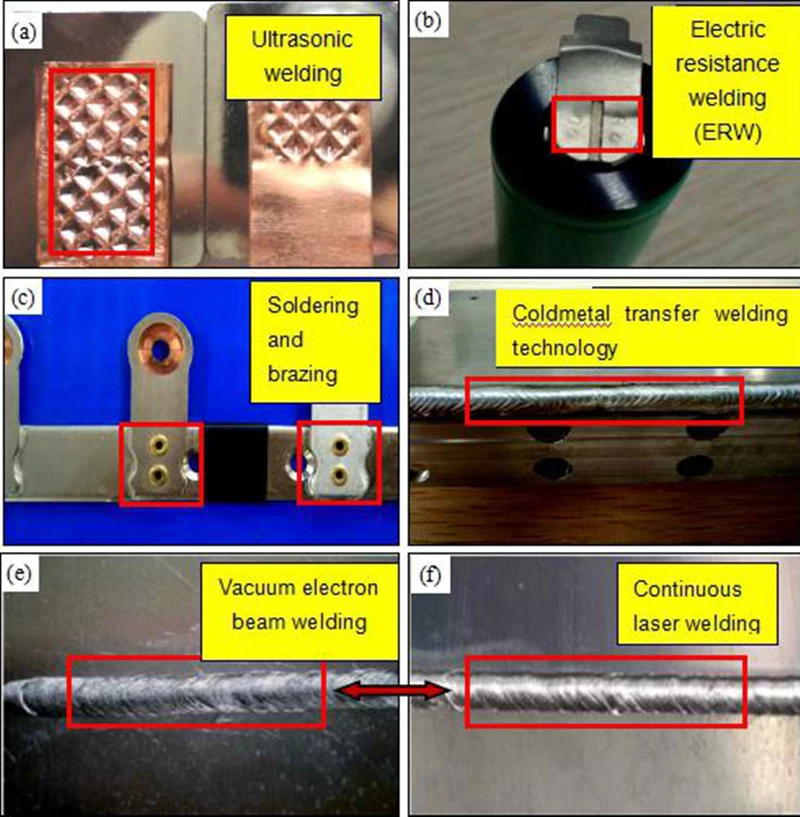

Many packaging technologies are applied to the actual production process of power battery: laser welding, electric resistance welding, ultrasonic welding, cold metal transfer welding technology (CMT), soldering and brazing, vacuum electron beam welding, etc. Appropriate welding methods and optimized process parameters play a significant role in saving the production cost of power battery and ensuring its uniformity, reliability, and safety. Flexible, efficient and precision, laser welding is one kind of non-contact process which can not only meets the performance requirements of the production process of the power battery but great advances the development of new energy power technology.

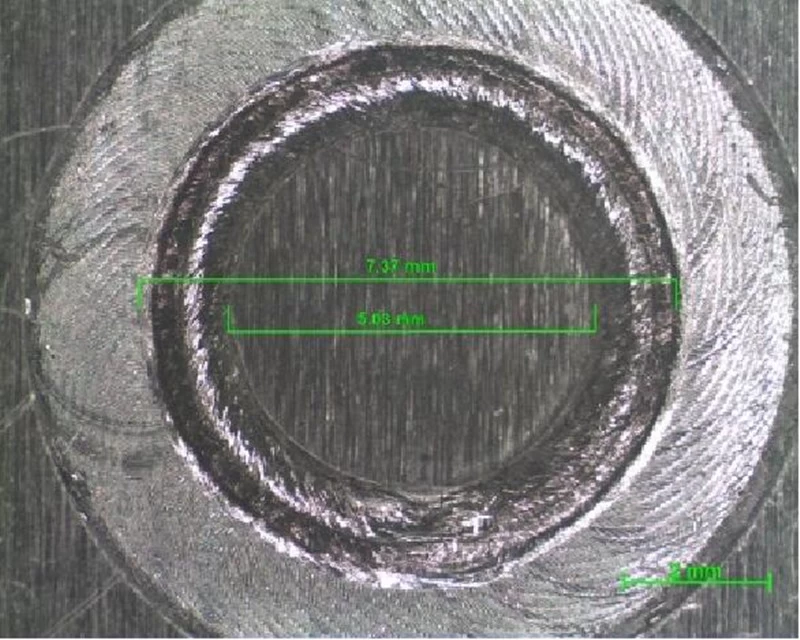

The following Figure shows some welding seam pictures with common welding methods, each of which has their advantages and disadvantages in certain application areas. The welding effect of vacuum electron beam welding and laser welding is almost the same since they both are high energy density welding. However, electron beam welding has high requirements for facility and working environment (vacuum), so there is great difficulty in mass production. Currently, it is only used in the production of some special supercapacitor. Laser welding has the advantages of: low welding material loss, no welding flux required, beautiful welding seam, stable performance, easy operation, good welding quality, the high degree of automation and process repeatability, which cannot be matched by other welding methods.

(a) Ultrasonic welding;

(b) Electric resistance welding (ERW);

(c) Soldering and brazing;

(d) Cold metal transfer welding technology;

(e) Vacuum electron beam welding;

(f) Continuous laser welding

Technical Parameter:

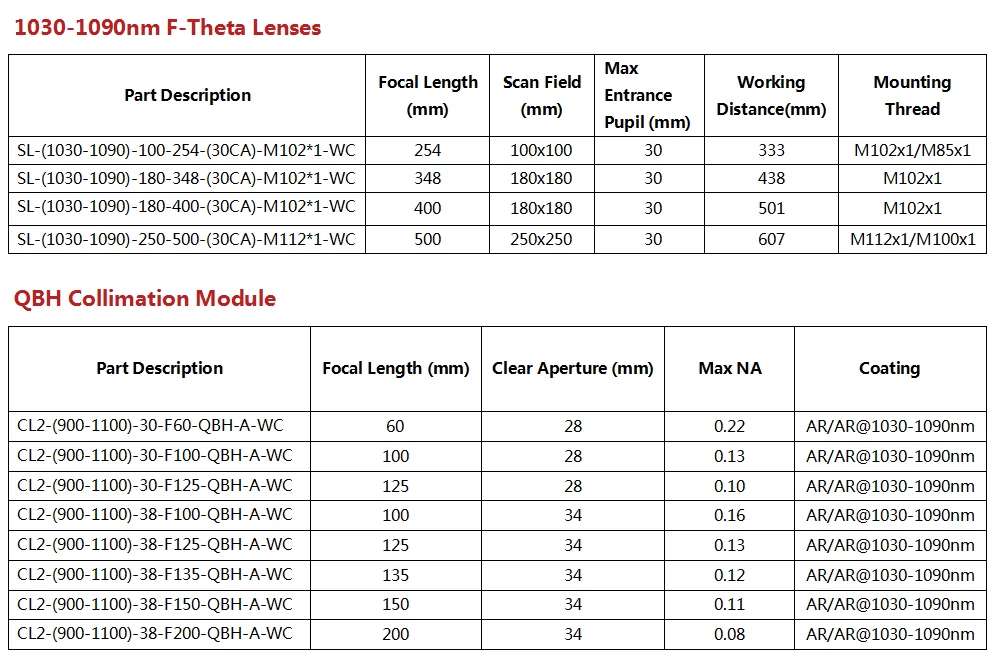

1.Wavelength: 1030~1090nm;

2.Laser Power:Multimode laser 4000-6000W;

3.Laser Power:Single mode laser 2500W

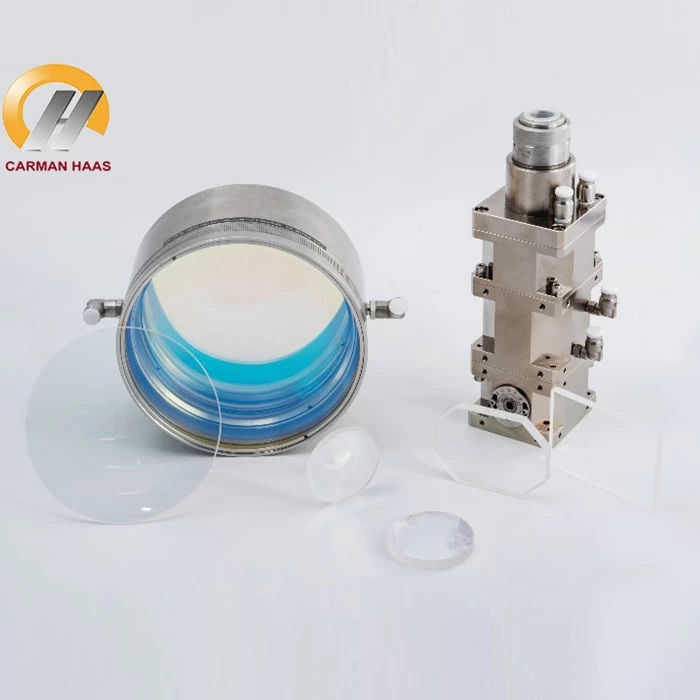

4.Collimating Lens FL(Optional);

5.f-θ Scan Lens FL (Optional);

6.Coaxial CCD Module,C connector;

7.Focus range:±3mm collimating lens moving;

8.Connector QBH;

9.Optional power detection:Sampling Rate 0.5%,Detection frequency 100Hz;

10.Air knife (Optional);

11.Safety System (Optional);

12.Focus indicator (Optional);

13.Air Cooling system (Optional);

14.Control system XY2-100;

15.Gross Weight: 18kg.

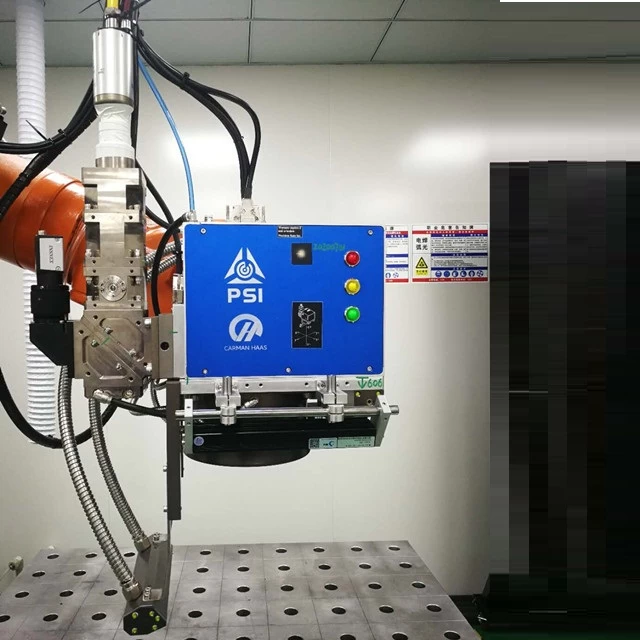

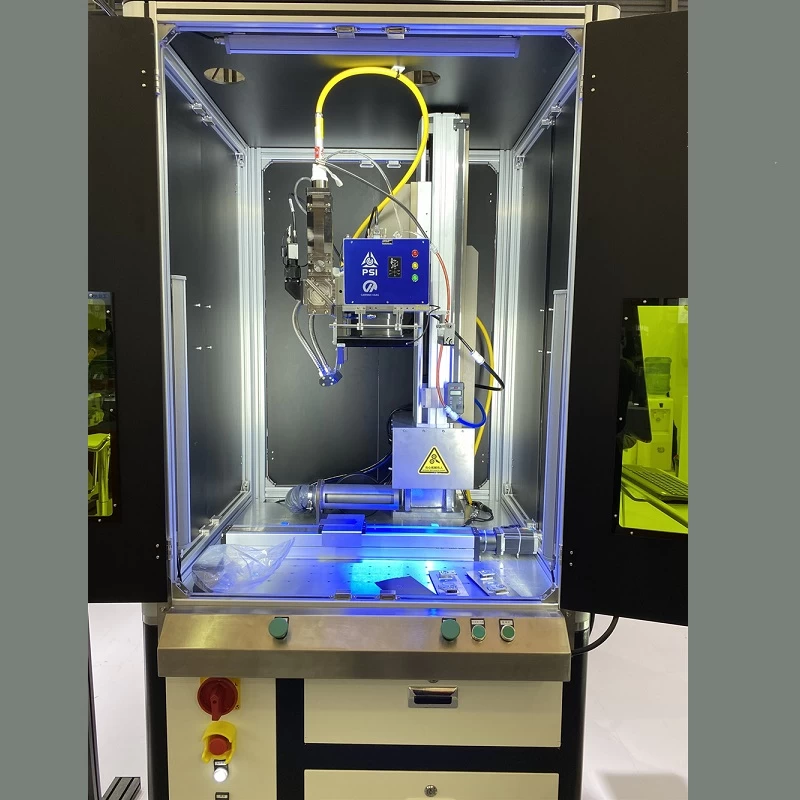

Galvo Head Laser Welding Factory China

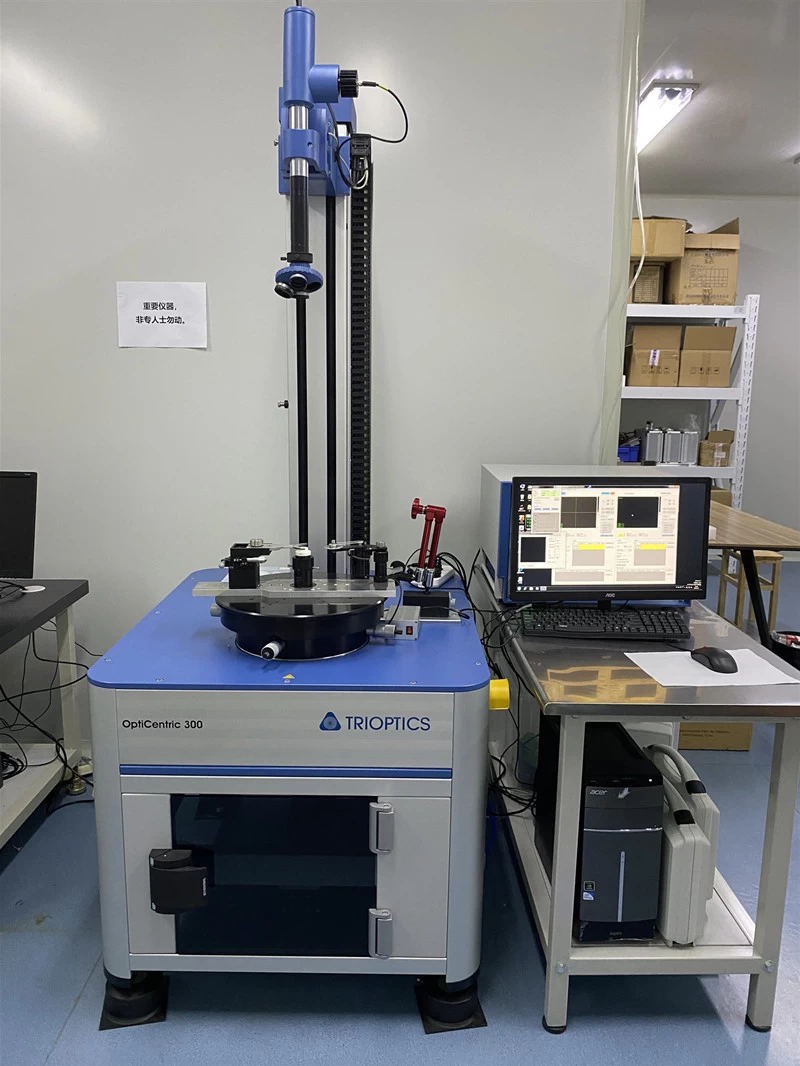

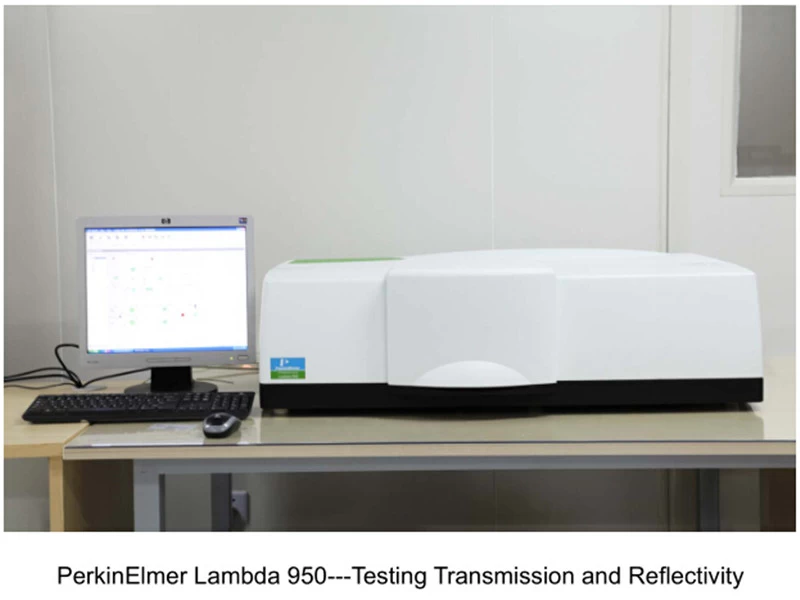

Factory

Certificate&Exhibition

Packing List

Return Policy:

Should returns be required:

Step 1) Contact us with this website email.

Step 2) Provide as much detail as possible about the problem you are having.

Step 3) Authorization to return the item will be issued.

Step 4) Return the item for the agreed replacement or refund.

Logistics:

(1)For Laser Optics order delivery,can be optional with DHL,UPS,FedEx,TNT,EMS,ets

(2)For Laser machine order delivery,can be optional with terms of EXWork FOB,CNF,CIF By Air or by Sea based on the buyer's forwarders or ours.

FAQ

Q1.Are you a manufacturer?

A1: Yes, we are professional and experienced manufacturer with our own molds and production lines.

Q2.How about quality of products?

A2: Our technicians and QC teams test the products one by one using aging line, professional devices and instruments to ensure the quality for all products.

Q3.How about price?

A3: We are a manufacturer and always offer our customers the most competitive prices.

Q4.How to place an order?

A4: Contact with online service, or sent email to us directly, we will reply to you with product price, specifications, packing etc. soon. Thank you.

Q5.May I send material to test marking performance?

A5: Yes! You are welcome to send material to test our superior quality and service.

Q6.Can I visit your factory?

A6: Yes, welcome to visit our factory at your convenient time.

Q7.How can I make OEM or ODM orders?

A7: We have different print processing for different OEM/ODM orders. Please contact us with online service or send email to us directly.

Q8. How should I pay for my orders?

A8: You can pay by T/T would be available for qualified bank and MOQ required for each order.

Tel:+86-18211675110

Wechat:wx136241032

Contact Person:John Wang

PDF Show:PDF

-and-Laser-Cleaning-system.jpg.webp)