- Browse Categories

- CO2 Laser Cutting

- Fiber Laser Cutting

- Laser Marking & Engraving

- Fiber Laser Welding

- Marking & Welding Machine

- Additive Manufacturing System

- Laser Etching System

- Ultra-fast Laser Processing

- Laser Cleaning System

- Subscribe

-

Get email updates on new products

- Certifications

-

- Laser Marking & Welding Machine

- Contact Us

-

Suzhou Carman Haas Laser Technology Co., Ltd

Address: No 155, West Road Suhong, Suzhou Industrial Park, Suzhou City, Jiangsu , P.R. China

Tel: +86-18211675110

Fax: +86-512-67678768

E-mail:wangxin@carmanhaas.com

https://www.carmanhaaslaser.com Contact Now

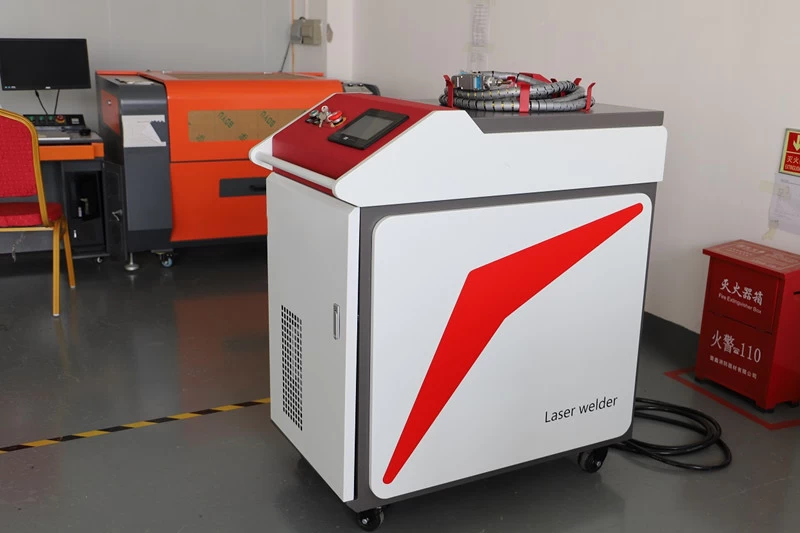

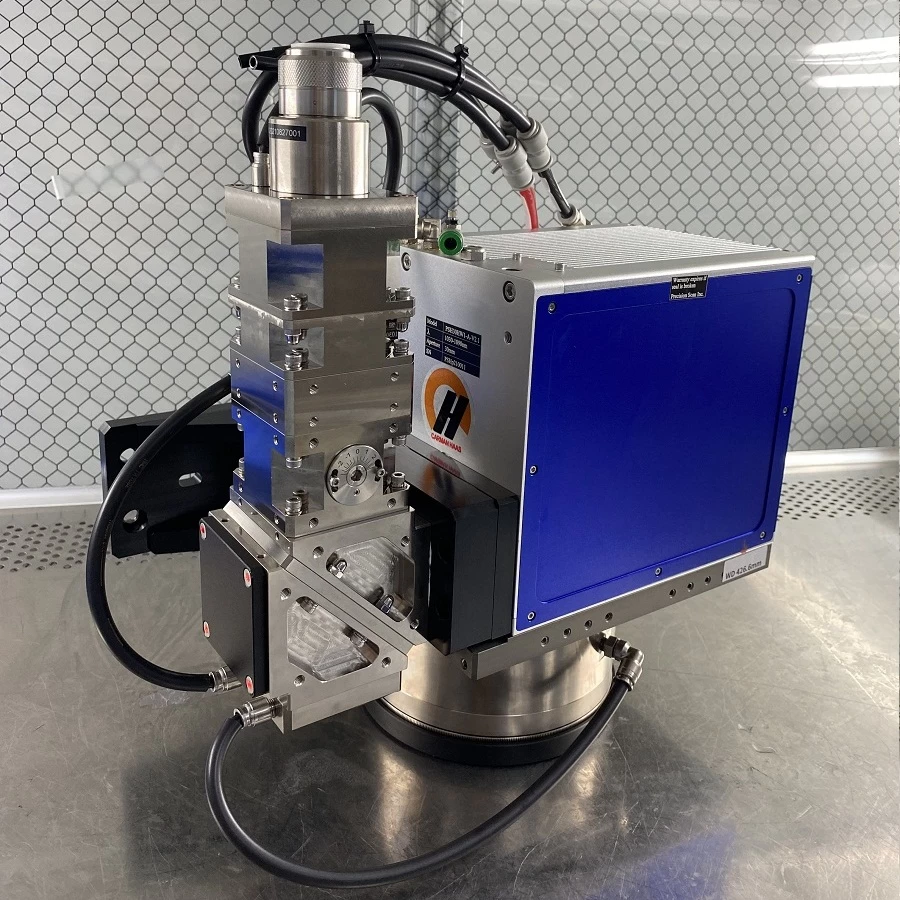

Wholesales Handheld Fiber Laser Welding Machine for Metal Stainless

- Brand Name: CARMAN HAAS

- Application: Laser Welding

- Laser Type: Fiber Laser

- Laser wavelength: 1030-1090nm

- Output Power: 1Kw/1.5Kw/2Kw

- Application Materials:0.5~4mm Carbon Steel, 0.5~4mm Stainless Steel, 0.5~2mm Aluminium alloy, 0.5~2mm Brass

- Certification: CE, ISO

| Product Information |

Product Description:

Fiber Laser Welding is a welding technology used to create a strong joint between several metal components with fiber laser. Fiber laser produces a beam of high-intensity that is concentrated into one spot. This concentrated heat source enables fine, deep welding with high welding speed.CARMAN HAAS Laser Technology (Suzhou) Co,Ltd. Wholesales 1000W Handheld Fiber Laser Welding Machine.

CARMANHAAS Supply 1kw/1.5kw/ 2kw fiber laser welding machines for sale.

Click Handheld Welding Supplier China for more products.

| Model: | CHLW-1000W/1500W/2000W |

| Laser power | 1000W / 1500W / 2000W |

| Laser Wave Length(nm) | Raycus : 1080±5 / IPG : 1070±10 |

| Working mode | Continuous/ Pulse |

| Welding Speed(mm/s) | 0-120 |

| Welding Gap | ≤ 1/5 of the thickness of sheet metal |

| Welding range(mm) | 0.5~4 carbon steel or stainless steel; 0.5~3 Aluminum |

| Fiber Length(m) | Standard 10 |

| Cooling Mode | Water cooling |

| Electromechanical | 380V/50HZ or 220V optional |

| Electromechanical | Temperature 10-35 ° C, humidity 20% -80% |

Laser welding vs Argon arc welding :

| Comparison item | Laser welding | Argon arc welding |

| Welding method | Spot welding or continuous | Spot welding |

| Applicable materials | Stainless steel, carbon steel, galvanized sheet,aluminum, etc. | Stainless steel, carbon steel, galvanized sheet |

| Thickness requirements | 0.5—4mm | 1—12mm |

| Workpiece deformation/ undercut |

Small | Big |

| Welding speed | 0—8m/min | 0—1m/min |

| Subsequent processing | Light or no sanding | Need polishing |

| Operation difficulty | Simple | Complex |

| Safety and environmental protection | Relatively safe and environmentally friendly | Not safe and environmentally friendly |

| Labor costs | General workers (can operate after simple training) | Professional welder |

| Wearing parts | Lens, nozzle | Argon |

| Supplies | Argon/Nitrogen | Argon |

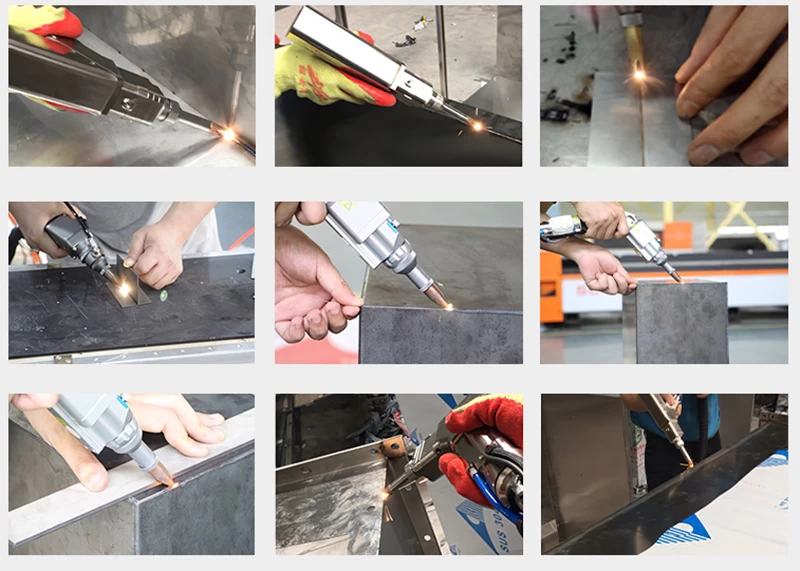

Applicable materials:

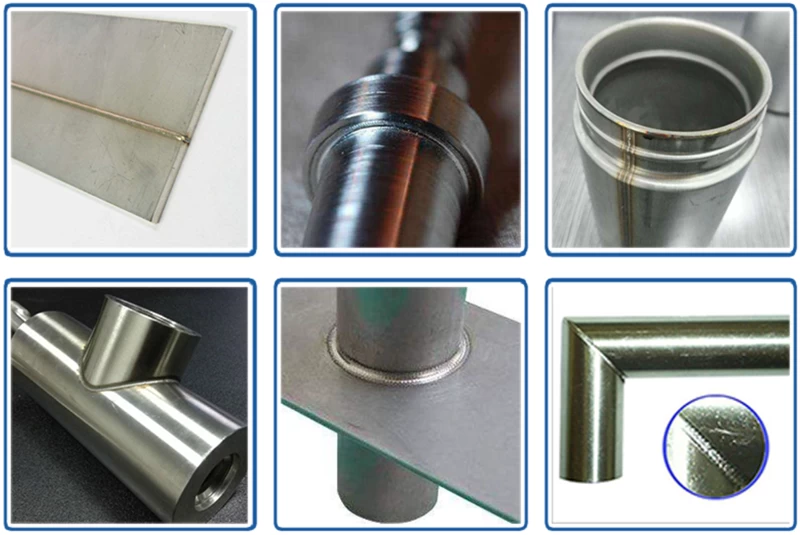

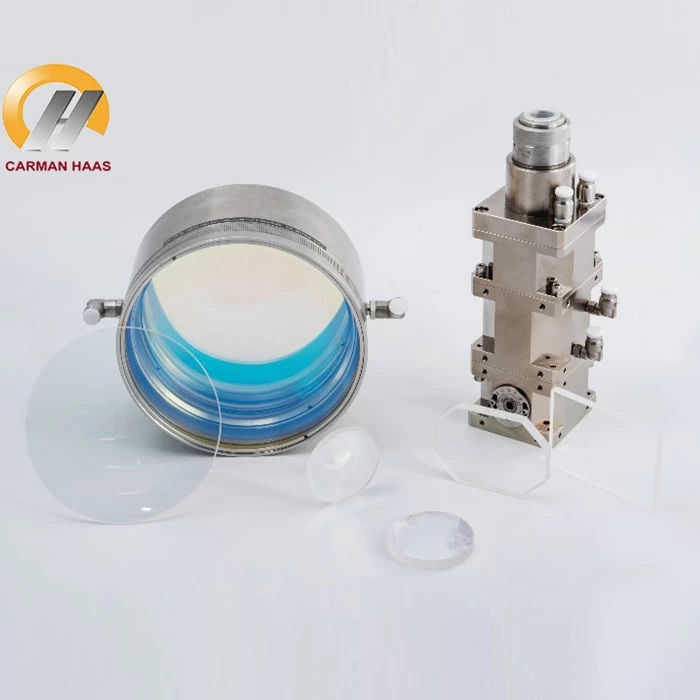

Laser welding machine can be used in welding stainless steel, luminum, copper, chromium, nickel, titanium and other metals or alloys.

1. 1000w/1kw handheld laser welder can weld 0.5-2mm steel;

2. 1500w/1.5kw fiber laser welder is used to weld 0.5-3mm steel;

3. 2000w/2kw laser welder can weld 0.5-4mm steel,0.5-3mm aluminum.

* The above data is based on the triangular light spot.

* Due to the difference of the plate and labor, please refer to the actual welding.

Our Service

》Pre-sale service

(1)Free sample marking

For free sample testing, please send us your file, we will do marking here and make video to show you the effect,or send sample to you for checking quality.

(2)Customized machine design

According to customer's application, we may revise our machine accordingly for customer's convenience and high production efficiency.

》 After-sale Service

(1)Installation:

After the machine reach the buyer’s site, the engineers from the seller are responsible for machine installation and commissioning by using the special tools under the help of the buyer. Buyer should pay for our engineer visa fee, air tickets, accommodation, meals etc.

(2)Training:

In order to provide training in safe operation, programming and maintenance, Machine Supplier shall provide qualified instructors after Buyer finally installs the equipment.

1.Mechanical maintenance training

2.Gas / electronic maintenance training

3.Optical maintenance training

4.Programming training

5.Advanced operation training

6.Laser safety training

Welding Samples :

| Factory |

| Certificate&Exhibition |

| Packing List |

| P/N | Item Name | Quantity | ||

| Hanheld Welding Machine | Carmanhaas | 1 set | ||

| Free Accessories | ||||

| 1 | Protective Lens | 2 pieces | ||

| 2 | Nozzle | some | ||

| 3 | Welding Head Cable | 1 set | ||

| 4 | User Manual & Laser Source Report | 1 piece | ||

| 5 | Laser Protective Googles | 1064nm | 1 piece | |

| Packing details: | One set in a wooden case |

| Single package size: | 110x64x48cm |

| Single gross weight | 264Kg |

| Delivery time : | Shipped in 2-5 days after receiving full payment |

Return Policy:

Should returns be required:

Step 1) Contact us with this website email.

Step 2) Provide as much detail as possible about the problem you are having.

Step 3) Authorization to return the item will be issued.

Step 4) Return the item for the agreed replacement or refund.

Logistics:

Optics order ship by DHL, UPS, FedEx, TNT, EMS etc

For Laser Machine order delivery, can be optional with terms of EXW, FOB, CNF, CIF by Express, Air Freight or Sea Freight based on the buyer’s forwarder or ours.

| FAQ |

Q1.Are you a manufacturer?

A1: Yes, we are professional and experienced manufacturer with our own molds and production lines.

Q2.How about quality of products?

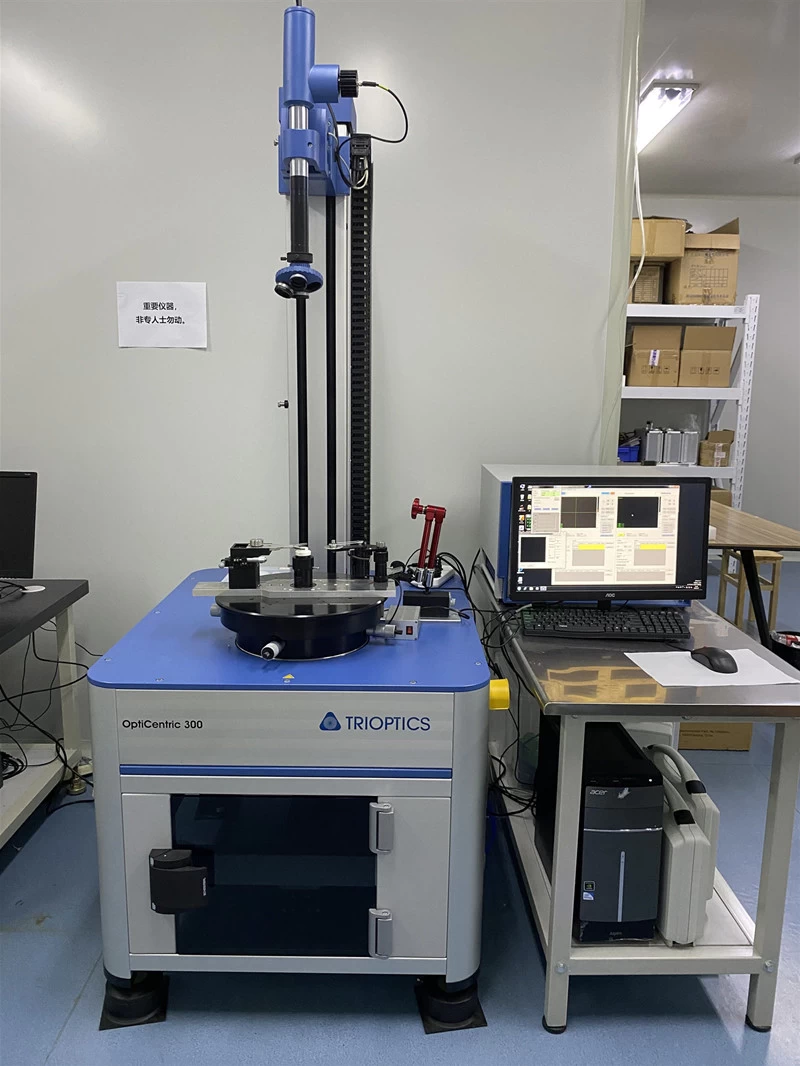

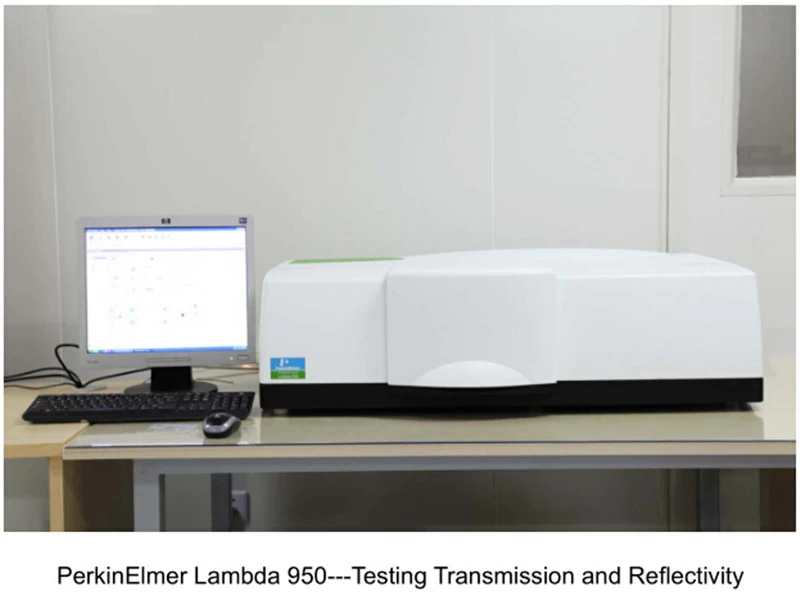

A2: Our technicians and QC teams test the products one by one using aging line, professional devices and instruments to ensure the quality for all products.

Q3.How about price?

A3: We are a manufacturer and always offer our customers the most competitive prices.

Q4.How to place an order?

A4: Contact with online service, or sent email to us directly, we will reply to you with product price, specifications, packing etc. soon. Thank you.

Q5.May I send material to test marking performance?

A5: Yes! You are welcome to send material to test our superior quality and service.

Q6.Can I visit your factory?

A6: Yes, welcome to visit our factory at your convenient time.

Q7.How can I make OEM or ODM orders?

A7: We have different print processing for different OEM/ODM orders. Please contact us with online service or send email to us directly.

Q8. How should I pay for my orders?

A8: You can pay by T/T would be available for qualified bank and MOQ required for each order.

Tel:+86-18211675110

Wechat:wx136241032

Contact Person:John Wang

PDF Show:PDF

-and-Laser-Cleaning-system.jpg.webp)