Bessel Ultra fast Cutting Head for Glass, Ceramic and Sapphire Laser Processing

Ultra-fast laser can be applied to the cutting, drilling and trenching of for optical materials mainly include transparent and brittle inorganic materials such as protective glass covers, optical crystal covers, sapphire lenses, camera filters, and optical crystal prisms. It has small chipping, no taper, high efficiency and high surface finish. We is laser cutting head protective lens window manufacturer can provide a complete set of Bessel beam long focal depth laser cutting heads.In addition, could also achieve material surface ink, PVD removal, and multifocal, long focal invisible cut of transparent material.

Characteristics:

(1)Precision polishing, Wavefront error< λ/10

(2)High transmittance: >99.5%

(3)High damage threshold: >2000GW/cm^2

Product advantages:

(1)Thickness of cuttable glass is 0.1mm-6.0mm

(2)Bessel Center focused on spot size 2um-5um (custom design)

(3)Cutting roughness: < 2um

(4)Cutting seam width:< 2um

(4)Cutting area has low thermal effect, small chipping and surface quality reaches the wavelength level

Specifications:

| Model | Max Entrance Pupil (mm) |

Min Working Distance (mm) |

Focus size (μm) |

Max Cutting Thickness(mm) |

Coating |

| BSC-OL-1064nm-1.01M | 20 | 14 | 1.4 | 1 | AR/AR@1030-1090nm |

| BSC-OL-1064nm-3.0M | 20 | 14 | 1.8 | 3 | AR/AR@1030-1090nm |

| BSC-OL-1064nm-6.0M | 20 | 14 | 2.0 | 6 | AR/AR@1030-1090nm |

Applications:

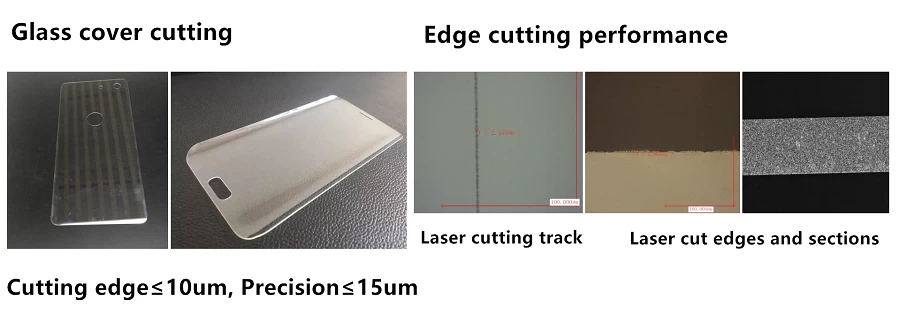

Glass Cover Cutting/Photovoltaic panel Cutting

CARMANHAAS Laser could offer ultra-fast laser cutting head and Bessel laser beam shaping cutting technology in the laser cutting processing solution for inorganic brittle optical materials such as glass cover plates. The laser forms a certain depth of internal burst area inside the transparent material. The stress in the burst area diffuses to the upper and lower surfaces of the transparent material, and then the material is separated by mechanical or CO2 laser.

For 3C industry, CARMANHAAS also could offer you , Objective Lens, Variable Zoom Laser Beam Expanders and Mirror. For More details, pls feel free to contact to us.