- Browse Categories

- CO2 Laser Cutting

- Fiber Laser Cutting

- Laser Marking & Engraving

- Fiber Laser Welding

- Marking & Welding Machine

- Additive Manufacturing System

- Laser Etching System

- Ultra-fast Laser Processing

- Laser Cleaning System

- Subscribe

-

Get email updates on new products

- Certifications

-

- Laser Marking & Welding Machine

- Contact Us

-

Suzhou Carman Haas Laser Technology Co., Ltd

Address: No 155, West Road Suhong, Suzhou Industrial Park, Suzhou City, Jiangsu , P.R. China

Tel: +86-18211675110

Fax: +86-512-67678768

E-mail:wangxin@carmanhaas.com

https://www.carmanhaaslaser.com Contact Now

Carman Haas Laser Cleaning Equipment on Sale Factory

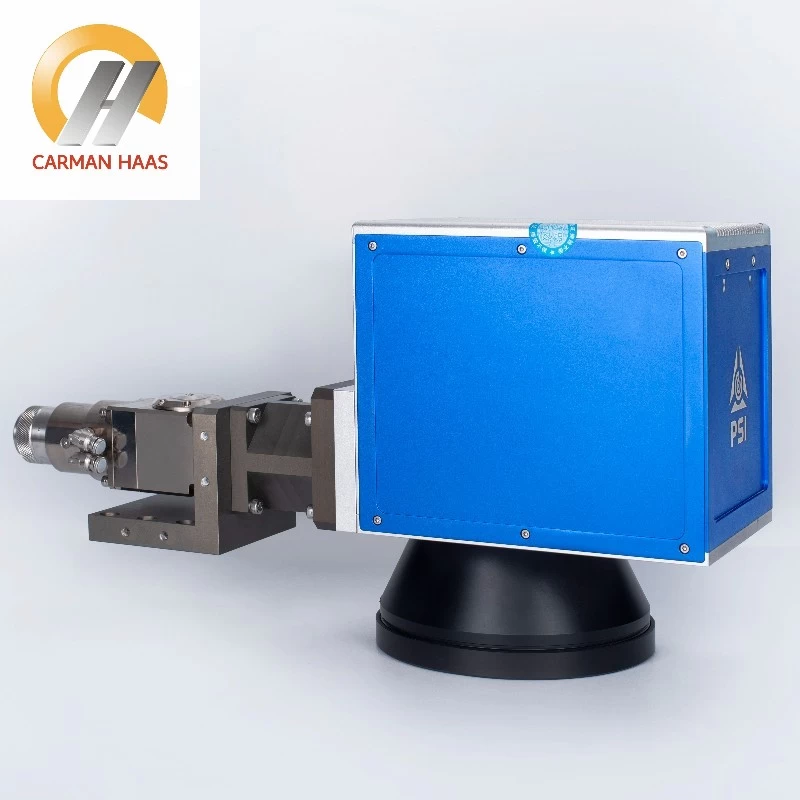

- Brand Name: CARMAN HAAS

- Wavelength: 1030-1090nm

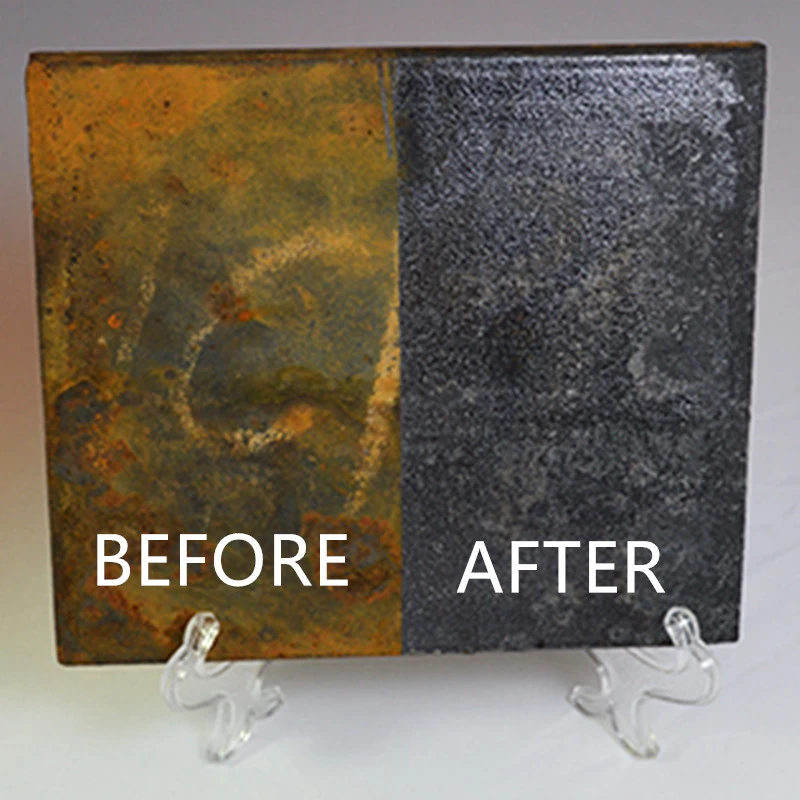

- Application: Tire Surface Cleaning

- Power: 1-2Kw CW Laser Source

- Place of Origin: Jiangsu, China (Mainland)

- Delivery time: within 24 hours after receiving payment

Product Description

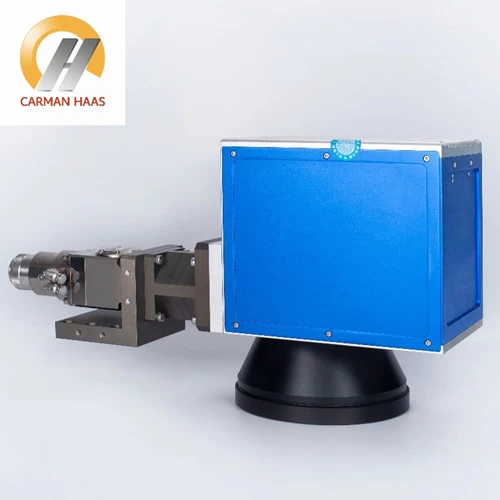

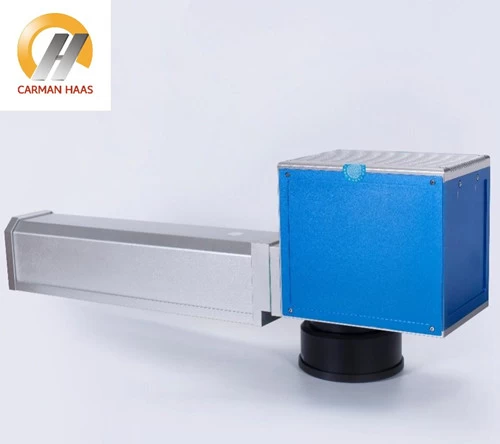

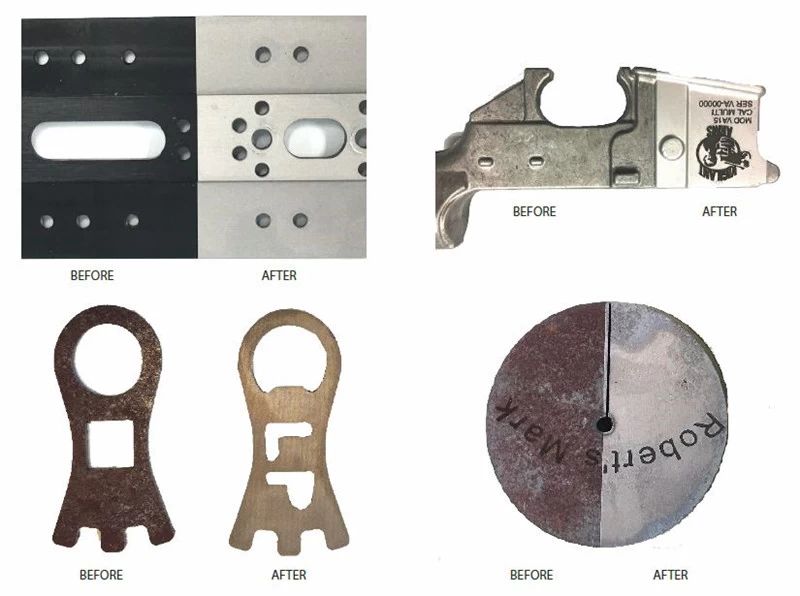

Carmanhaas offer professional laser cleaning system. Commonly used optical solutions: the laser beam scans the working surface through the galvanometer system and the scan lens to clean the entire working surface. Widely used in metal surface cleaning, special energy laser sources can also be applied to non-metallic surface cleaning. (Laser Cleaning Equipment on Sale Factory)

Click Factory Laser Cleaning Price China to know more products

Advantage:

1.No abrasive materials are used, with no problems of contaminant separation and disposal;

2.No solvents are used - chemical-free and environmentally friendly process;

3.Spatially selective – cleaning only the area required, saving time and costs by ignoring regions that don’t matter;

4.Non-contact process never degrades in quality;

5.Easily automated process that can lower operating costs by eliminating labor while giving greater consistency in results.

Technical Parameters

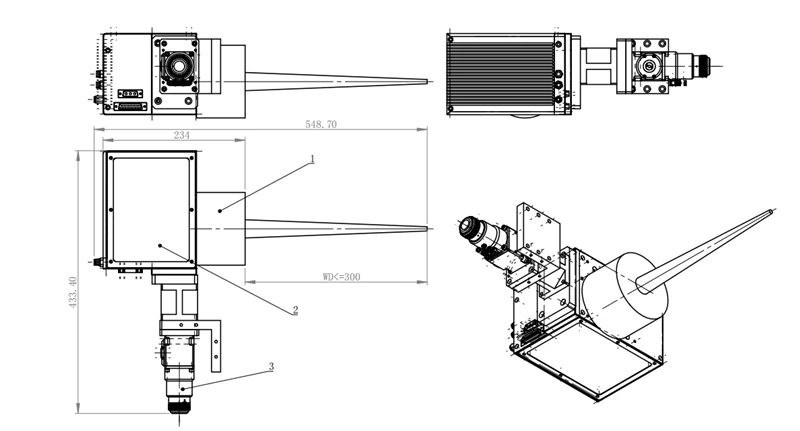

| Model | PSH14HW | PSH20HW |

| Maximum allowed average laser power(1) | 1000W | 2000W |

| Damage threshold for pulsed operation(1) | 30J/ cm2 | 30J/ cm2 |

| Cooling | Water cooling | Water cooling |

| Aperture (mm) | 14 | 20 |

| Effective Scan Angle(2) | ±12 ° | ±12° |

| Tracking Error | ≤ 0.2ms | ≤ 0.28ms |

| Step Response Time(1% of full scale) | ≤ 0.4 ms | ≤ 0.7 ms |

| Positioning/ jump(3) | < 15 m/s | < 9 m/s |

| Precision marking speed(4) | < 3 m/s | < 2 m/s |

| Good writing quality(3) (4) | 650 cps | 450 cps |

| High writing quality(3) (4) | 500 cps | 300 cps |

| Linearity | 99.9% | 99.9% |

| Repeatability | ≤ 3 urad | ≤ 3 urad |

| Over 8 hours long-term offset drift (after 10 min warm-up) | ≤ 30 urad | ≤ 30 urad |

| Over 8 hours long-term gain drift (after 10 min warm-up) | ≤ 30 urad | ≤ 30 urad |

| Operating Temperature Range | 25℃±10℃ | 25℃±10℃ |

| Signal Interface | Analog: ±10V Digital: XY2-100 protocol |

Analog: ±10V Digital: XY2-100 protocol |

| Input Power Requirement (DC) | ±15V@ 4A Max RMS | ±15V@ 4A Max RMS |

Note:

(1)Applicable for wavelength 1030-1090nm.

(2) All angles are in mechanical degrees.

(3) With F-Theta objective f = 163mm. Speed value varies correspondingly with different focal lengths.

(4) Repeatability and temperature drift are measured within this speed.

(5) Single-stroke font with 1 mm height.

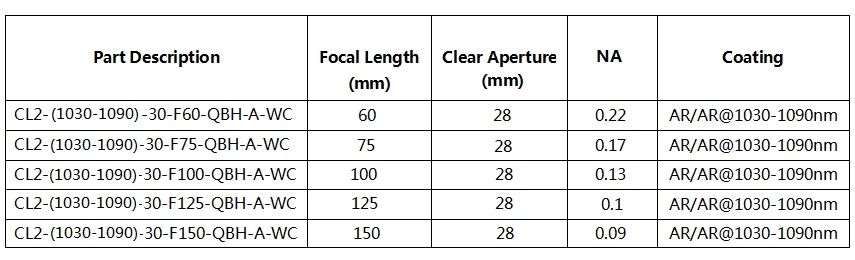

QBH collimating optical module(1030nm - 1090nm):

Note:

According Laser Source Core Diameter and BBP choose correct Collimating lens

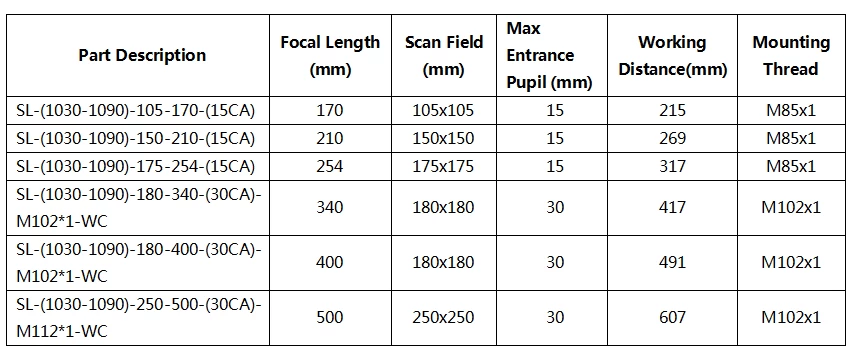

1030nm - 1090nm F-Theta Lens:

Note: *WC means Scan Lens with water-cooling system

Why are more manufacturers using laser cleaning for material preparation?

Laser cleaning offers multiple advantages over traditional approaches. It does not involve solvents and there is no abrasive material to be handled and disposed of. Compared with other processes that are less detailed, and frequently manual processes, laser cleaning is controllable and can be applied only to specific areas of a part, can be easily automated to maximize productivity, and provides the guaranteed repeatability demanded by an increasing number of quality standards.

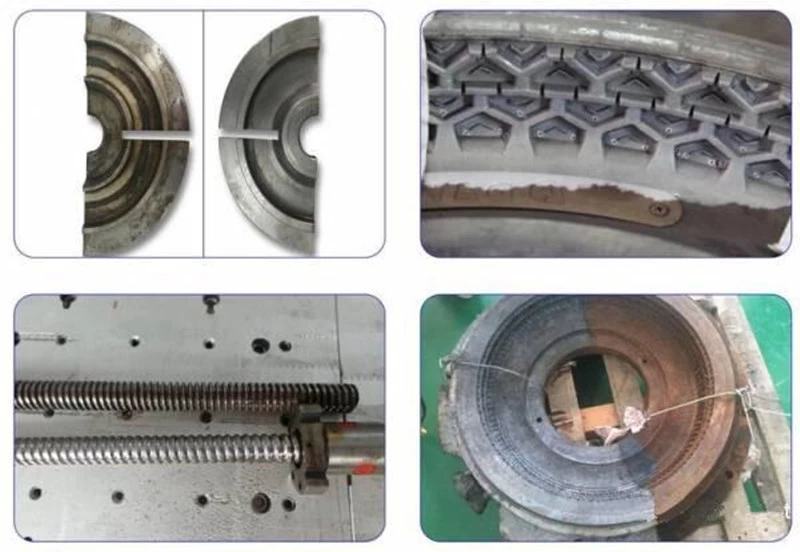

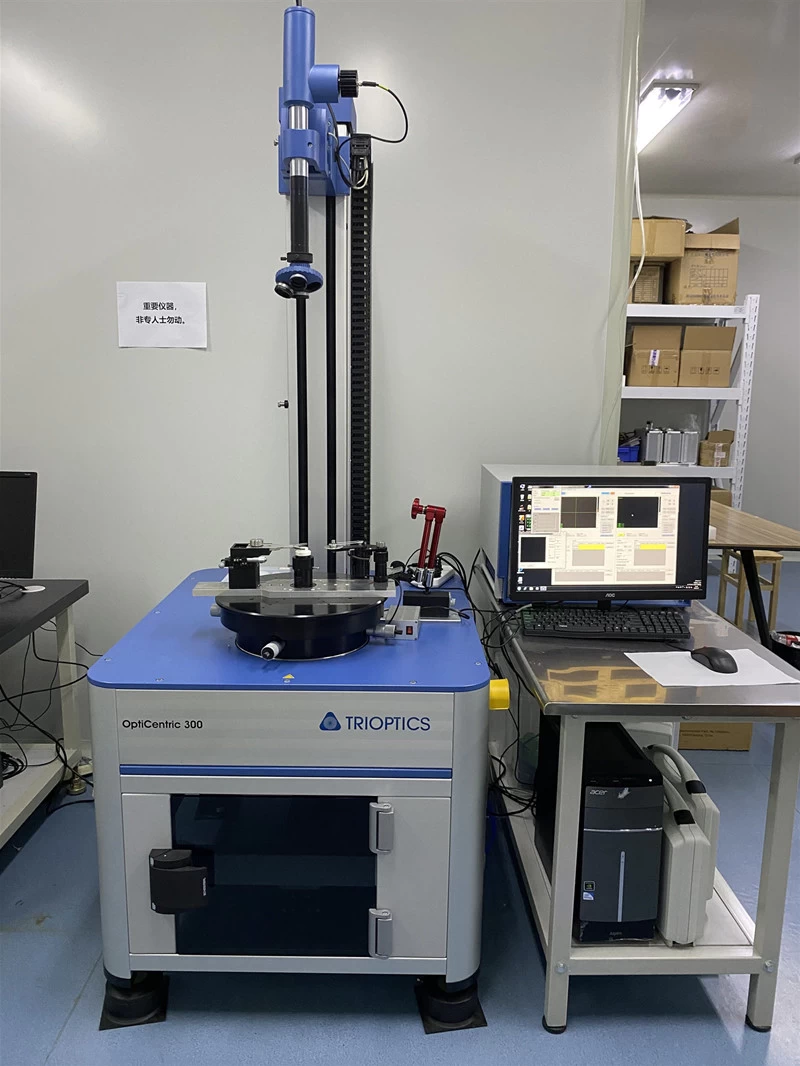

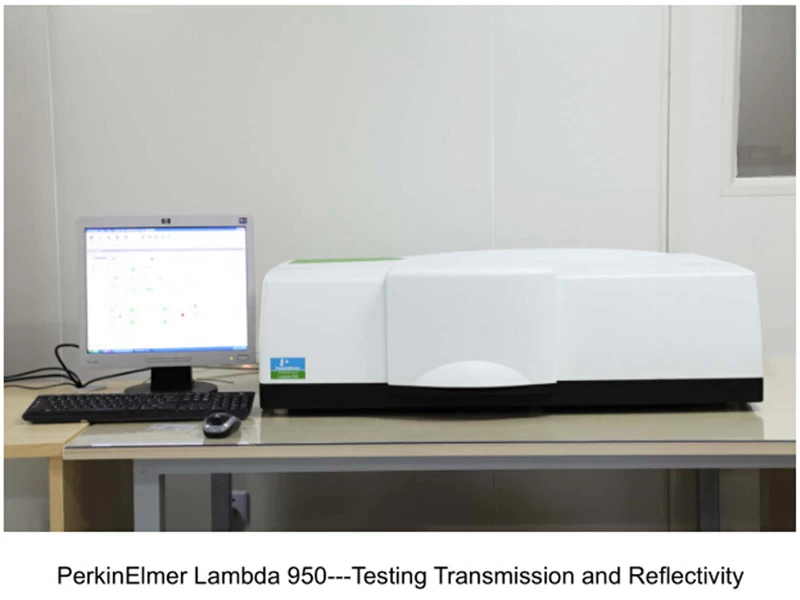

Factory

Certificate&Exhibition

Packaging & Shipping

Return Policy:

Should returns be required:

Step 1) Contact us with this website email.

Step 2) Provide as much detail as possible about the problem you are having.

Step 3) Authorization to return the item will be issued.

Step 4) Return the item for the agreed replacement or refund.

Logistics:

(1)For Laser Optics order delivery,can be optional with DHL,UPS,FedEx,TNT,EMS,ets

(2)For Laser machine order delivery,can be optional with terms of EXWork FOB,CNF,CIF By Air or by Sea based on the buyer's forwarders or ours.

FAQ

Q1.Are you a manufacturer?

A1: Yes, we are professional and experienced manufacturer with our own molds and production lines.

Q2.How about quality of products?

A2: Our technicians and QC teams test the products one by one using aging line, professional devices and instruments to ensure the quality for all products.

Q3.How about price?

A3: We are a manufacturer and always offer our customers the most competitive prices.

Q4.How to place an order?

A4: Contact with online service, or sent email to us directly, we will reply to you with product price, specifications, packing etc. soon. Thank you.

Q5.May I send material to test marking performance?

A5: Yes! You are welcome to send material to test our superior quality and service.

Q6.Can I visit your factory?

A6: Yes, welcome to visit our factory at your convenient time.

Q7.How can I make OEM or ODM orders?

A7: We have different print processing for different OEM/ODM orders. Please contact us with online service or send email to us directly.

Q8. How should I pay for my orders?

A8: You can pay by T/T would be available for qualified bank and MOQ required for each order.

Tel:+86-18211675110

Wechat:wx136241032

Contact Person:John Wang

PDF Show:PDF