- Browse Categories

- CO2 Laser Cutting

- Fiber Laser Cutting

- Laser Marking & Engraving

- Fiber Laser Welding

- Marking & Welding Machine

- Additive Manufacturing System

- Laser Etching System

- Ultra-fast Laser Processing

- Laser Cleaning System

- Subscribe

-

Get email updates on new products

- Certifications

-

- Laser Marking & Welding Machine

- Contact Us

-

Suzhou Carman Haas Laser Technology Co., Ltd

Address: No 155, West Road Suhong, Suzhou Industrial Park, Suzhou City, Jiangsu , P.R. China

Tel: +86-18211675110

Fax: +86-512-67678768

E-mail:wangxin@carmanhaas.com

https://www.carmanhaaslaser.com Contact Now

Wholesales Optical Lenses, For 3D Printing SLM/SLS/SLA

- Brand Name: CARMAN HAAS

- Place of Origin: Jiangsu, China (Mainland)

- SLM optical system supplier china

- 3D printer optical system

- Wavelength: 1030-1090nm/355nm/10.6um

- Application: 3D Printing Additive manufacturing

- Delivery time: within 24 hours after receiving payment

- Main Parts: Galvo Scanner, F-Theta Lenses, Beam Expander, Protective Window, QBH Collimating Optical Module

SLM Product Description:

SLM or Selective laser melting, is a type of metal additive manufacturing or 3D printing. Often, the terms SLM and direct metal laser sintering (DMLS) are used interchangeably. However, the two technologies differ slightly, in that SLM melts pure metals while DMLS fuses metal alloys.

SLM is one of the most exciting 3D printing technologies available today and is utilized both for rapid prototyping and mass production. The range of metal alloys available is fairly extensive. The end result has properties equivalent to those manufactured via traditional manufacturing processes.

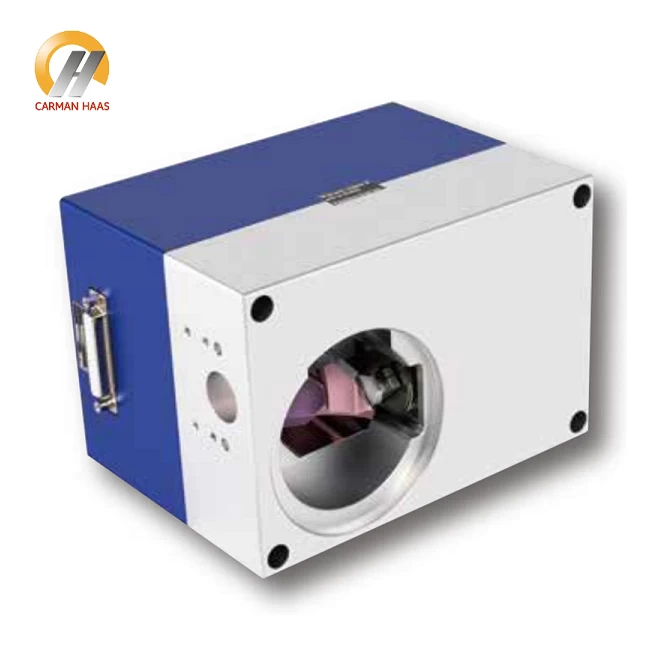

China 3D Galvo Scanner Factory Price

CARMANHAAS could offer customer the optical system mainly includes QBH optical module, Galvanometer Scanner and F-THETA scan lens, Beam expander, Protective Window, etc. The Power could reach 1000W (Single Mode Laser).

SLM Product Advantage:

(1)Power up to single mode 1KW;

(2)Long-term stability, low temperature drift;

(3)The fastest scanning speed is up to 5000mm/s;

(4)Precise positioning with resolution up to 1um.

F-Theta Scan Lens For 3D Printing

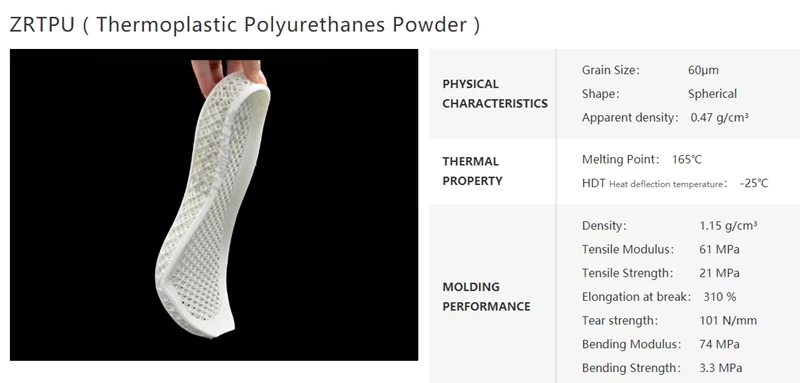

SLS Product Description:

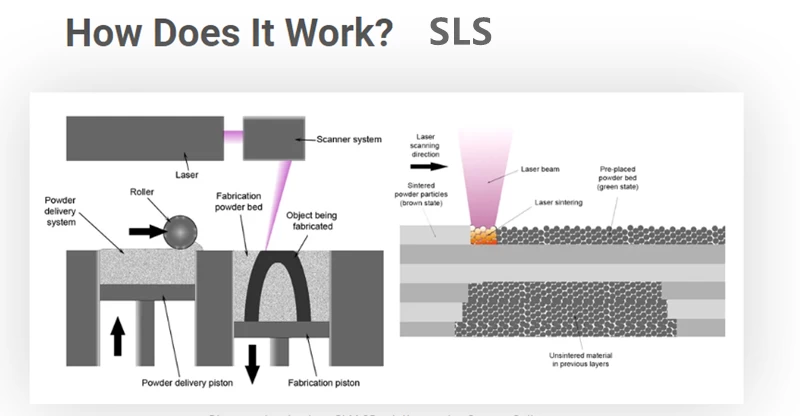

SLS Printing uses selective CO₂ laser sintering technology which sinters plastic powders(ceramic or metal powders with binding agent) into solid cross-sections layer by layer until a three-dimensional part is built. Before making the parts, need to fill the build chamber with nitrogen and rise the chamber temperature. When the temperature is ready, a computer controlled CO₂ laser selectively fuses powdered materials by tracing cross-sections of the part on the surface of a powder bed and then a new coat of materiel is applied for the new layer. The working platform of the powder bed will go one layer down and then the roller will pave a new layer of the powder and the laser will selectively sinter the cross-sections of the parts. Repeat the process until the parts completed.

CARMANHAAS could offer customer Dynamic optical scanning system with High speed · High precision · High quality function.

Dynamic optical scanning system:means front focusing optical system, achieves zooming by a single lens movement, which consists of a moving small lens and two focusing lenses. The front small lens expands the beam and the rear focusing lens focuses the beam. The use of the front focusing optical system, because the focal length can be elongated, thereby increasing the scanning area, is currently the best solution for large-format high-speed scanning. Generally used in large-format machining or changing working distance applications, such as large-format cutting, marking, welding, 3D printing, etc.

SLS Product Advantage:

(1)Galvanometer Aperture:14mm、20mm、30mm;

(2)Large-format scanning processing, the format can reach 2000mmx2000mm, and ensure high consistency and high roundness of the focused spot;

(3)Large spot incidence, so that the finer the spot size is required;

(4)Advanced servo control algorithm and efficient photoelectric sensing positioning technology;

(5)Support XY2-100 international general agreement.

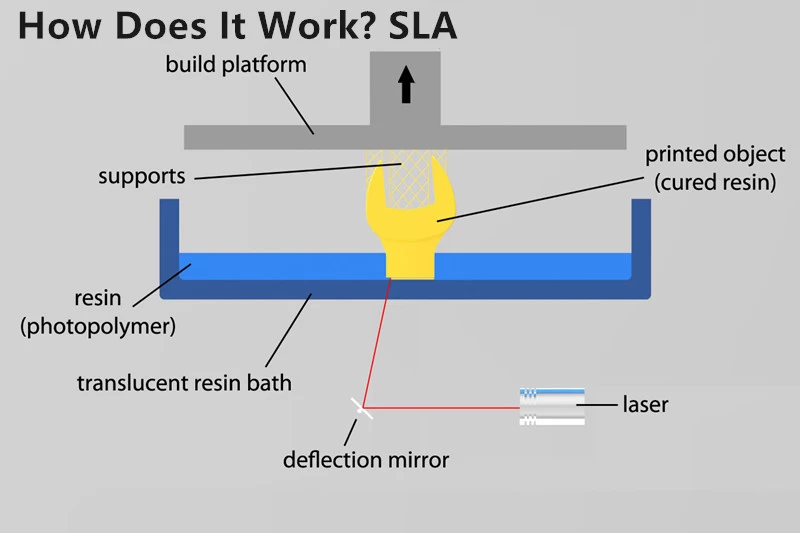

SLA Product Description:

SLA (Stereolithography) is an additive manufacturing process that works by focusing an UV laser on to a vat of photopolymer resin. With the help of computer aided manufacturing or computer aided design(CAM/CAD) software, the UV laser is used to draw a pre-programmed design or shape on to the surface of the photopolymer vat. Photopolymers are sensitive to ultraviolet light, so the resin is photochemically solidified and forms a single layer of the desired 3D object. This process is repeated for each layer of the design until the 3D object is complete.

CARMANHAAS could offer customer the optical system mainly includes fast Galvanometer Scanner and F-THETA scan lens, Beam expander, Mirror, etc.

Return Policy:

Should returns be required:

Step 1) Contact us with this website email.

Step 2) Provide as much detail as possible about the problem you are having.

Step 3) Authorization to return the item will be issued.

Step 4) Return the item for the agreed replacement or refund.

Logistics:

(1)For Laser Optics order delivery,can be optional with DHL,UPS,FedEx,TNT,EMS,ets

(2)For Laser machine order delivery,can be optional with terms of EXWork FOB,CNF,CIF By Air or by Sea based on the buyer's forwarders or ours.

Q1.Are you a manufacturer?

A1: Yes, we are professional and experienced manufacturer with our own molds and production lines.

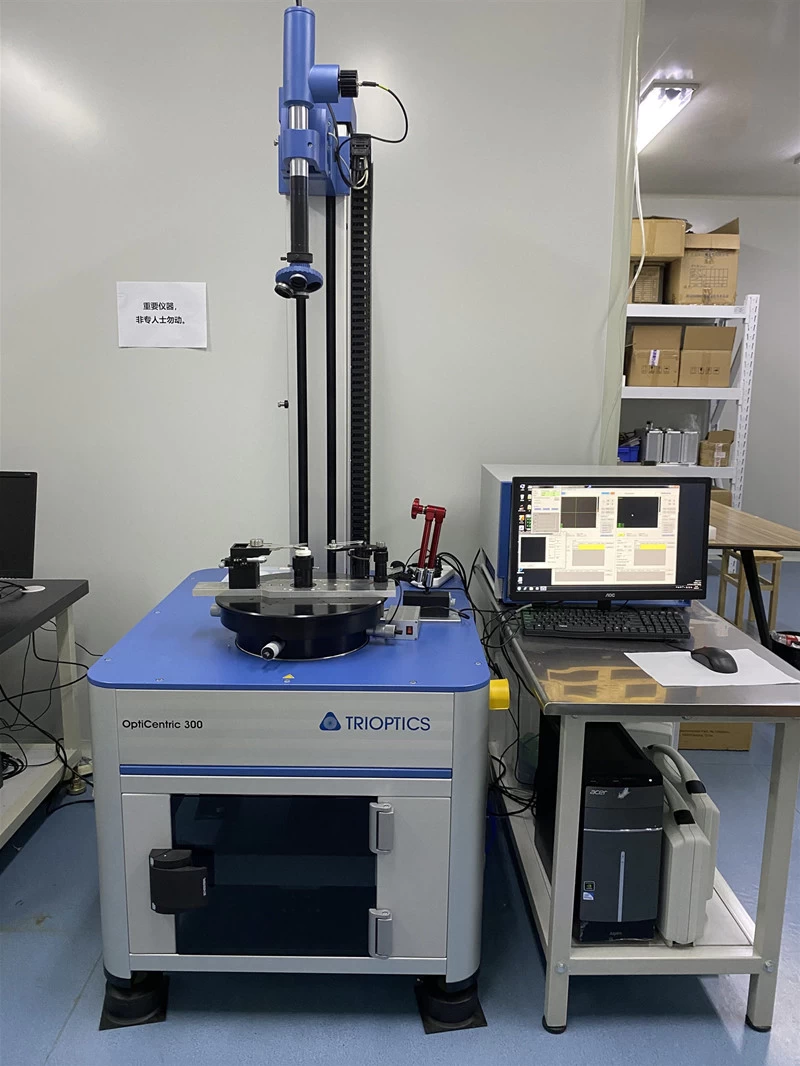

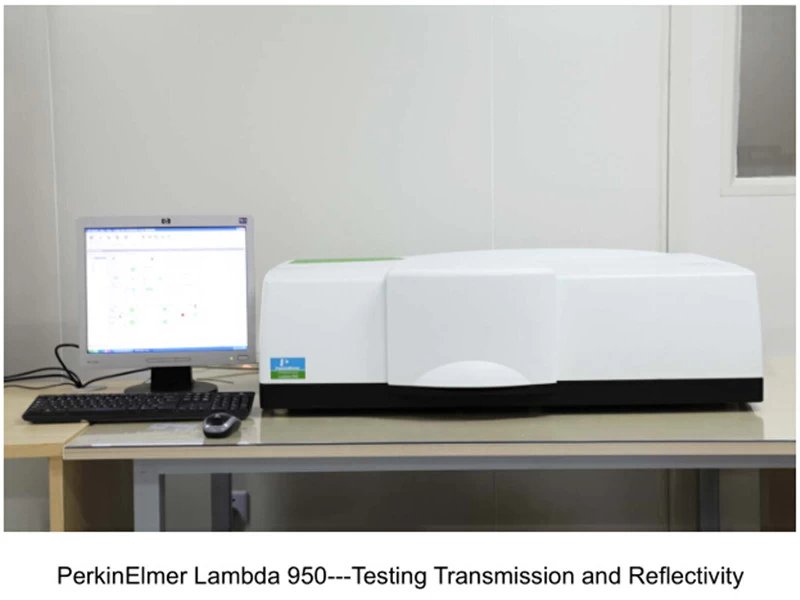

Q2.How about quality of products?

A2: Our technicians and QC teams test the products one by one using aging line, professional devices and instruments to ensure the quality for all products.

Q3.How about price?

A3: We are a manufacturer and always offer our customers the most competitive prices.

Q4.How to place an order?

A4: Contact with online service, or sent email to us directly, we will reply to you with product price, specifications, packing etc. soon. Thank you.

Q5.May I send material to test marking performance?

A5: Yes! You are welcome to send material to test our superior quality and service.

Q6.Can I visit your factory?

A6: Yes, welcome to visit our factory at your convenient time.

Q7.How can I make OEM or ODM orders?

A7: We have different print processing for different OEM/ODM orders. Please contact us with online service or send email to us directly.

Q8. How should I pay for my orders?

A8: You can pay by T/T would be available for qualified bank and MOQ required for each order.

Tel:+86-18211675110

Wechat:wx136241032

Contact Person:John Wang

PDF Show:PDF

-Optical-System-for-3D-Printing-and-Additive-manufacturing-Processing.jpg.webp)