CO2 laser cutting machine-cutting wood products

CO2 laser cutting machine is mainly used to cut non-metallic materials, such as rubber, plastic, cloth, leather, wool, crystal, bamboo products, wood products, etc. Wood board laser cutting is to use a high-power density laser beam to scan the surface of the material to heat the material to thousands to tens of thousands of degrees Celsius in a short time to melt or vaporize the material, and then use high-pressure gas to remove the melted or vaporized material from the slit. It is blown away in the middle to achieve the purpose of cutting the material. The incision has no mechanical stress, no shearing burr, high processing accuracy, good repeatability, and does not damage the surface of the material.

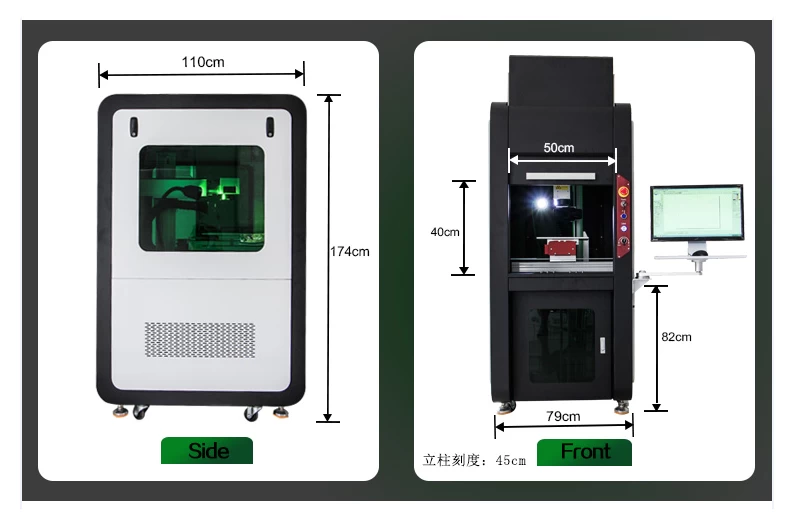

CO2 Laser Engraving Cutting Machine wholesales

At present, wood cutting is mostly carried out in the form of traditional saw blade cutting, but it will produce a lot of pollution such as sawdust and noise. Using a laser cutting machine to cut wood can not only reduce noise, but also reduce the generation of sawdust particles and reduce the harm to the human body. It is very fast when cutting thin boards, such as acrylic board and wood material board. And the output of CO2 laser cutting machine is continuous laser, and the quality of cut wood section is better than that of traditional cutting. Rough, torn or fluffy wood grain on the cut surface is not obvious, but is covered with a thin carbonized layer.

Many people worry that the cutting surface will turn black after the laser cutting machine is processed. The first thing to note is that if you are cutting a thicker plank, it is difficult to avoid blackening. Because the laser focus energy melts the plank, Therefore, there will be blackening during the cutting process, that is, the cutting edge is carbonized.

Maybe everyone knows that to avoid the carbonization effect of the wood board laser cutting machine, it is correct to use high speed and low power, but some are misunderstood. They think that the faster the speed, the better, and the lower the power, the better. In order to reduce the blackening, they use fast and low power to cut multiple times. This is very bad, and the carbonization effect may be darker than normal. If you want to cut beautiful results, you still need to look for professional debugging.

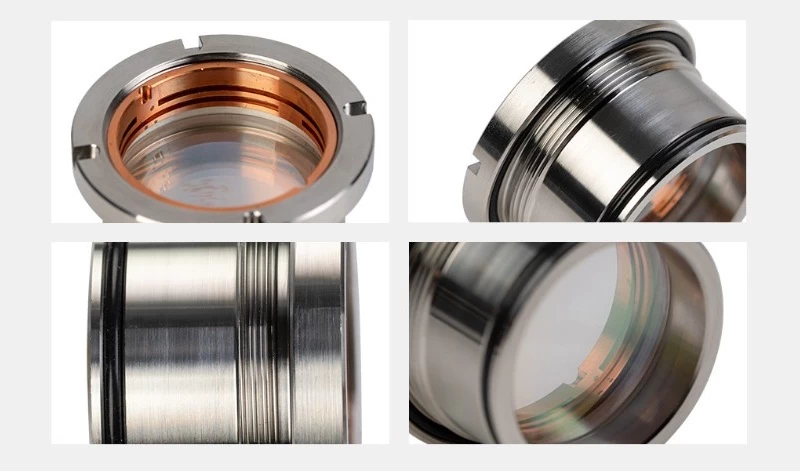

CARMAN HAAS Laser Technology (Suzhou) Co,Ltd. supply all kinds of accessories and good working performance laser marking machine, all our products are good quality with CE ISO certificated, to be leader supplier in china with best price. Welcome Contact us for more information about laser equipment: Autofocusy Fiber Laser Cutting Head.