- Parcourir les catégories

- Machine de marquage laser

- Découpe laser fibre

- Marquage et gravure laser

- Soudage laser fibre

- Découpe laser CO2

- Système de fabrication additive

- Système de gravure au laser

- Traitement laser ultra-rapide

- Tube laser CO2 et alimentation électrique1

- S\'abonner

-

Recevez des mises à jour par e-mail sur les nouveaux produits

- Certifications

-

- Machine de marquage et de soudage laser

- Nous contacter

-

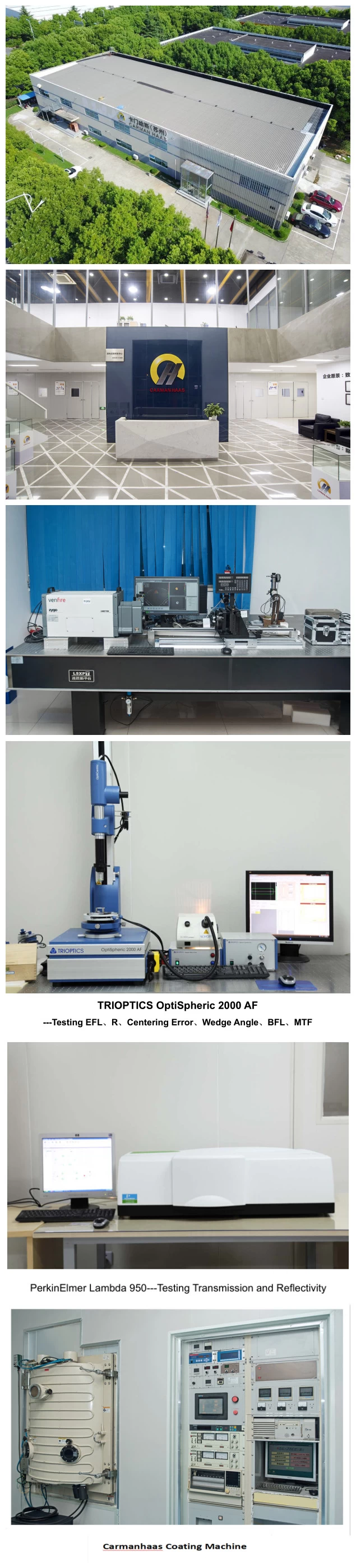

Carman Haas laser Technology (Suzhou) Co., Ltd

Adresse: no 155, West Road Suhong, Suzhou Industrial Park, Suzhou City, Jiangsu, p.r. Chine

Tél: + 86-512-67678768

Fax: + 86-512-67678768

E-mail:sales@carmanhaas.com

URWeb:www.carmanhaas.com Contacter maintenant

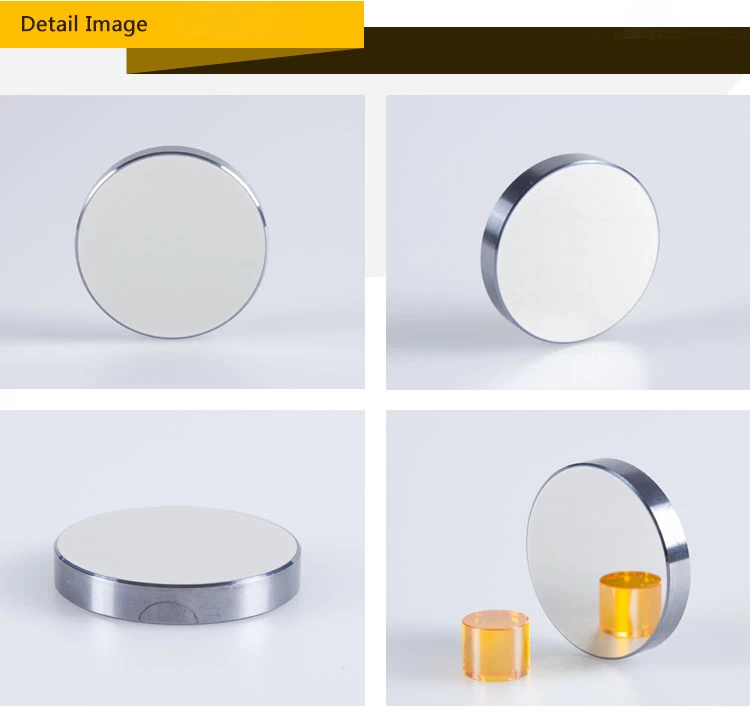

Miroir réfléchissant Carmanhaas Mo D25 T3 pour machine de marquage laser CO2

- Lieu d'origine: Jiangsu, Chine (continentale)

- Nom de marque: Carman Haas

- Numéro de modèle: RMO-203

- Nom du produit: MORE MORE

- Application: Machine de découpe laser CO2

- Type de laser: Tube laser CO2

- Longueur d'onde: 10.60um

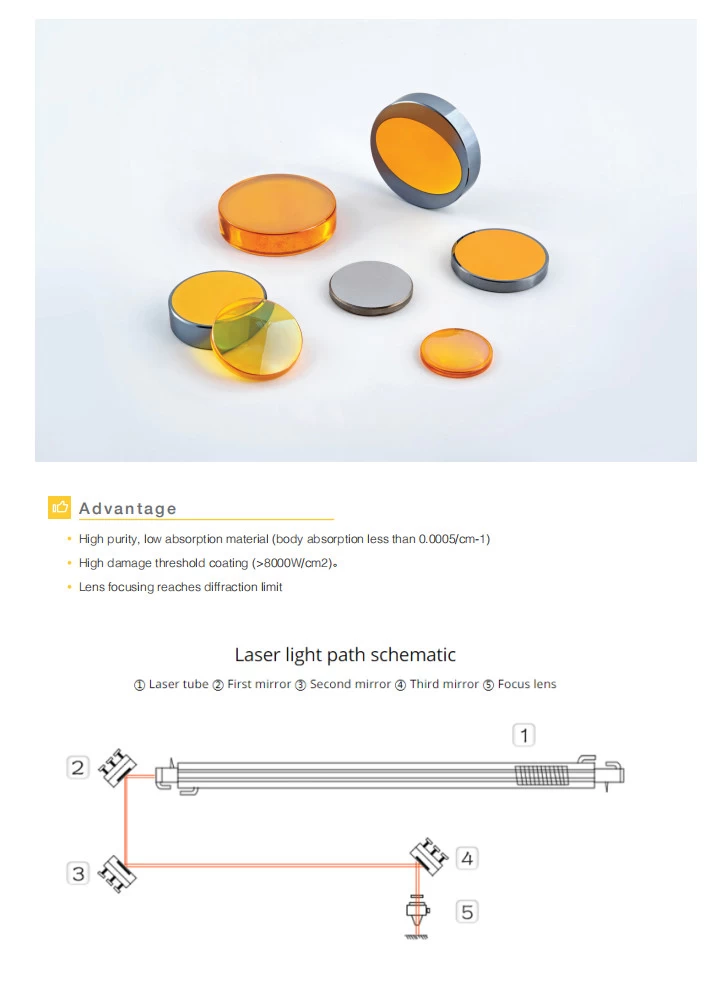

Miroir de réflexion laser, utilisé dans la cavité laser comme miroir d'extrémité ou pli-miroir, et dans le faisceau de Delivety comme miroir réfléchissant. Le substrat est typiquement silicium, Cu et MO. Silicon est le substrateur de miroir le plus couramment utilisé à sa bonne "figure de mérite" propriétés. CU en raison de sa conductivité élevée est généralement utilisée dans les systèmes laser à haute puissance. Surface résistante à la commande adaptée aux besoins spécifiques de l'environnement physique, il est généralement non revêtu. Dans la cavité laser à faible puissance, telle que le tube de tube de verre et le tube de tube de verre, le miroir d'extrémité couramment utilisé du silicium, le rayon de courbure peut être durci en fonction de la demande du client.

spécification

| Matériel | Molybdène |

|

|

| Tolérance de diamètre | + 0,0 / -0,1mm | ||

| Tolérance d'épaisseur | ± 0.1mm | ||

| Ouverture claire | > = 90% de diamètre | ||

| Gratter / creuser | S1: 40-20, S2: beau fond | ||

| Parallélisme | <1' | ||

| Bênant | <0.2×45° | ||

| enrobage | Réflectivité du revêtement HR |

| P / n | Diamètre | E.t. | Matériel | enrobage | Spécialité |

| (mm) | (mm) | ||||

| RMO-193 | 19 | 3 | Molybdène | déshabillage | Durabilité, convient à toutes sortes de supports physiques environnement |

| RMO-203 | 20 | 3 | |||

| RMO-253 | 25 | 3 | |||

| RMO-303 | 30 | 3 | |||

| RMO-383 | 38.1 | 3 | |||

| RMO-403 | 40 | 3 | |||

| RMO-505 | 50.8 | 5 | |||

Tél:+86-18211675110

Wechat:wx136241032

Personne de contact:Alice

PDF Afficher:Pdf