- Browse Categories

- CO2 Laser Cutting

- Fiber Laser Cutting

- Laser Marking & Engraving

- Fiber Laser Welding

- Marking & Welding Machine

- Additive Manufacturing System

- Laser Etching System

- Ultra-fast Laser Processing

- Laser Cleaning System

- Subscribe

-

Get email updates on new products

- Certifications

-

- Laser Marking & Welding Machine

- Contact Us

-

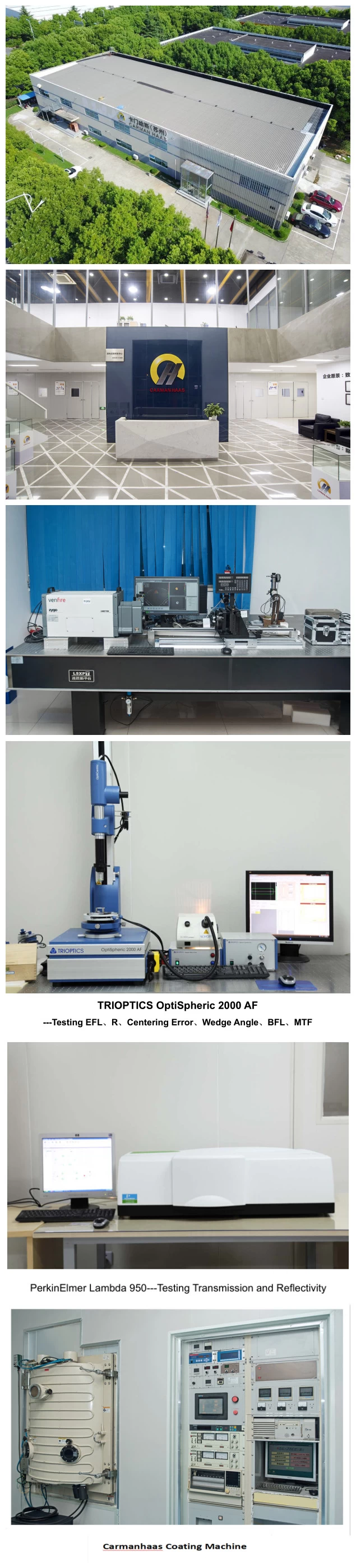

Suzhou Carman Haas Laser Technology Co., Ltd

Address: No 155, West Road Suhong, Suzhou Industrial Park, Suzhou City, Jiangsu , P.R. China

Tel: +86-18211675110

Fax: +86-512-67678768

E-mail:wangxin@carmanhaas.com

https://www.carmanhaaslaser.com Contact Now

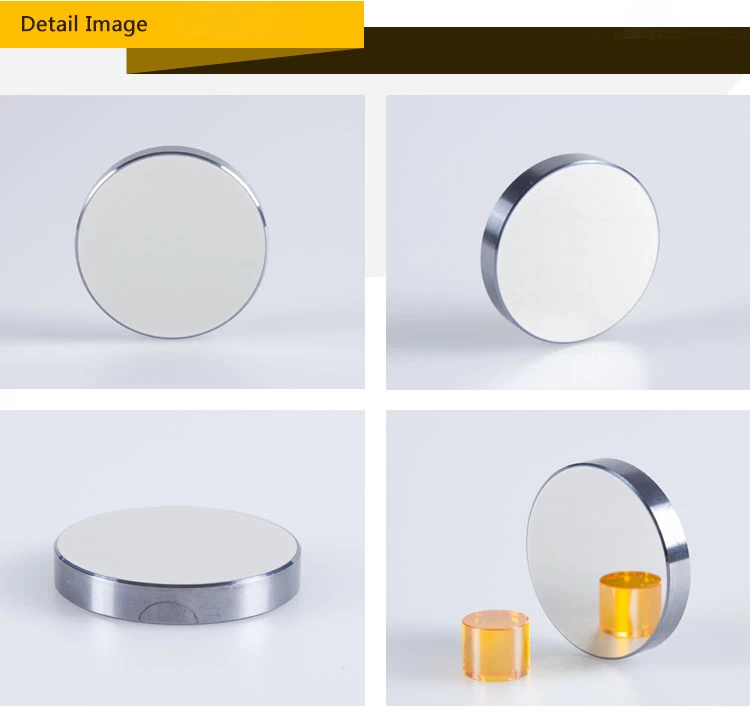

Carmanhaas Mo Reflective Mirror D25 T3 For Co2 Laser Marking Machine

- Place of Origin: Jiangsu, China (Mainland)

- Brand Name: Carman Haas

- Model Number: RMO-203

- Product name: MO Mirror

- Application: CO2 Laser Cutting Machine

- Laser type: Co2 laser Tube

- Wavelength: 10.60um

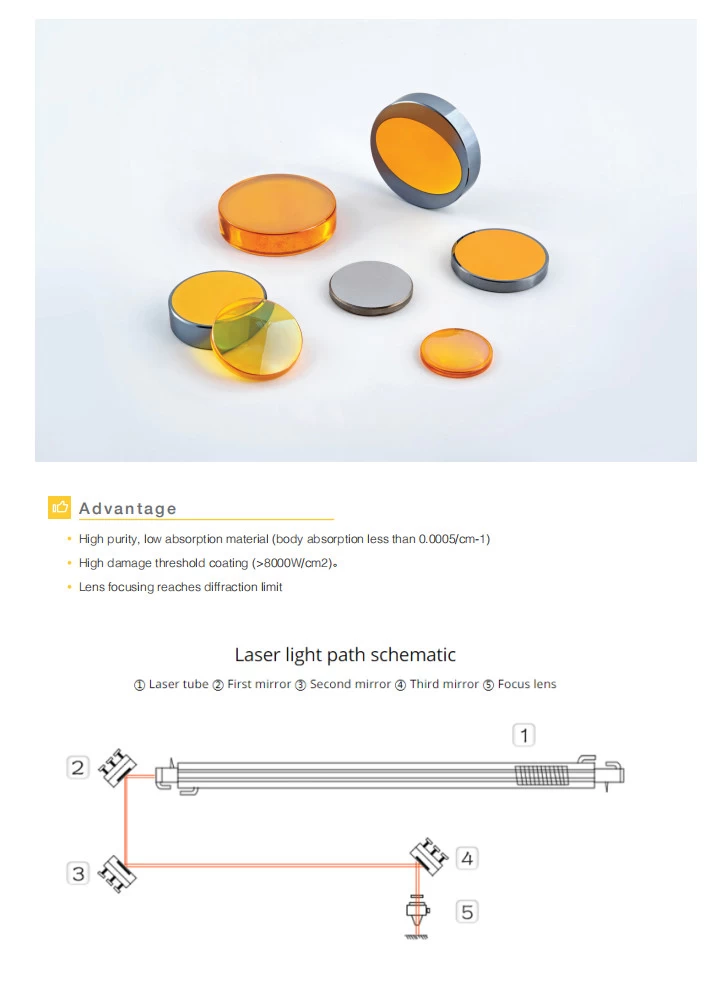

Laser reflection mirror, used in the laser cavity as end mirror or foldmirror, and in the beam delivety as reflective mirror. Substrate is typically silicon, Cu and Mo. Silicon is the most commonly used mirror substratedue to its good "figure of merit" properties. Cu because of its highthermal conductivity is generally used in high-power laser systems. Mo-resistant surface suitable for the specific needs of the physical environment,it is generally uncoated. In the low-power laser cavity, such as Glass tube andRF tube, end mirror commonly used silicon, the radius of curvature can becustomized according to customer demand.

Specification

| Material | Molybdenum |

|

|

| Diameter Tolerance | +0.0/-0.1mm | ||

| Thickness Tolerance | ±0.1mm | ||

| Clear Aperture | >= 90% Diameter | ||

| Scratch/Dig | S1:40-20,S2:Fine ground | ||

| Parallelism | <1' | ||

| Bevelling | <0.2×45° | ||

| Coating | HR Coating Reflectivity |

| P/N | Diameter | E.T. | Material | Coating | Speciality |

| (mm) | (mm) | ||||

| RMO-193 | 19 | 3 | Molybdenum | Uncoating | Durability, suitable for all kinds of harsh physical environment |

| RMO-203 | 20 | 3 | |||

| RMO-253 | 25 | 3 | |||

| RMO-303 | 30 | 3 | |||

| RMO-383 | 38.1 | 3 | |||

| RMO-403 | 40 | 3 | |||

| RMO-505 | 50.8 | 5 | |||

Tel:+86-18211675110

Wechat:wx136241032

Contact Person:John Wang

PDF Show:PDF