Attention should be paid to using laser cutting machine to protect the lens

1. Laser lenses are relatively brittle and afraid of falling; pay attention when disassembling: do not use too much force, and do not collide with hard objects. There is an antireflection film on the surface, which is afraid of pollution, humidity, oiliness, and scratching; therefore, it is required to provide dry and degreasing air during work. Do not handle the laser lens directly by hand, because skin oil will affect the surface of the lens. Cause permanent damage. On the contrary, we can operate by wearing gloves and its special kit. For smaller lenses, it is more convenient to use optical tweezers or vacuum tweezers. No matter what method is used to clamp the laser lens, it can only be clamped along the non-optical surface, such as the frosted edge of the mirror plaque;

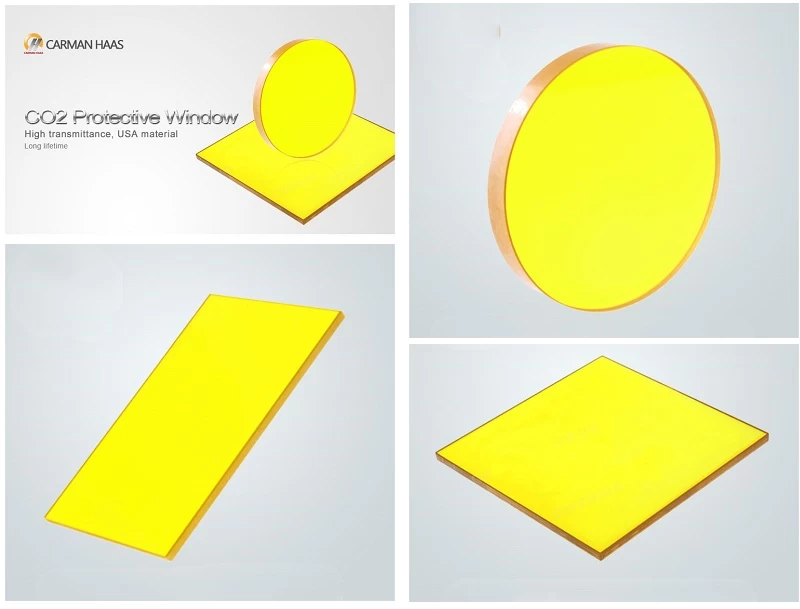

Fiber laser cutting head protective lens factory

2. Under normal circumstances, it is necessary to check the hygienic condition of the laser lens surface before use and before and after cleaning. Because most contaminants and surface defects are relatively small in size, we often need to use magnifying equipment when inspecting lenses. In addition to magnifying equipment, sometimes we need to use a brighter light to illuminate the optical surface to enhance the specular reflection intensity of surface contaminants and defects, so that contaminants and defects can be found more easily; when the lens surface is found to be dirty, we should Use alcohol to wipe in time;

laser cutting head protective lens window manufacturer

3. You should develop a good habit of cleaning the lenses on a regular basis. It is recommended to clean the reflective lenses every 5-7 days as a cycle, and for the concentrated lenses 1-2 days as a cycle. Of course, we also need to use clean wipes or cotton swabs and industrial alcohol to prevent damage by other pollutants. When the high level of cleanliness is still not achieved after cleaning for many times, you need to pay attention to replacing the laser lens to ensure the processing efficiency of the laser cutting machine, so as not to affect the production efficiency.

CARMAN HAAS is laser cutting head protective lens window manufacturer, provides a variety of laser cutting machine and optical lenses, Welcome to contact us.