Principle and Application of 3D Laser Scanner Technology

The 3D laser scanning system mainly consists of 3D laser scanner, computer, power supply system, bracket and supporting software. As one of the main components of the system, the 3D laser scanner is also composed of laser transmitter, receiver, time counter, motor-controlled rotating filter, control circuit board, microcomputer, CCD camera, and software.

F-Theta Scan Lens For 3D Printing

Laser ranging technology is one of the main technologies of 3D laser scanners. The principle of laser ranging is mainly based on four types: pulse ranging, phase ranging, laser triangulation, and pulse-phase. The three-dimensional laser scanners currently used in the field of surveying and mapping are mainly pulse ranging method and phase ranging method.

Application field

Three-dimensional laser scanners have been successfully used in cultural relics protection, urban building surveys, topographic mapping, mining, deformation monitoring, factories, large structures, pipeline design, aircraft and ship manufacturing, highway and railway construction, tunnel engineering, bridge reconstruction and other fields. application.

1. Scanning of infrastructure such as subway, municipal, civil engineering, etc.

Infrastructure measurement methods are transitioning from traditional single-point measurement methods to laser scanning methods. The 3D laser scanner combines high efficiency and high performance, measurement-level accuracy, integrated data processing procedures, and provides complete 3D laser scanning. solution.

2. Digital management and transformation of factories, petrochemicals, ships, etc.

The 3D laser scanner can quickly acquire rich point cloud data and high-definition images. The data can be seamlessly imported into professional design software for modeling, design, drawing and inspection. Some special post-processing software can use point clouds for reverse modeling. Digitalize the factory quickly.

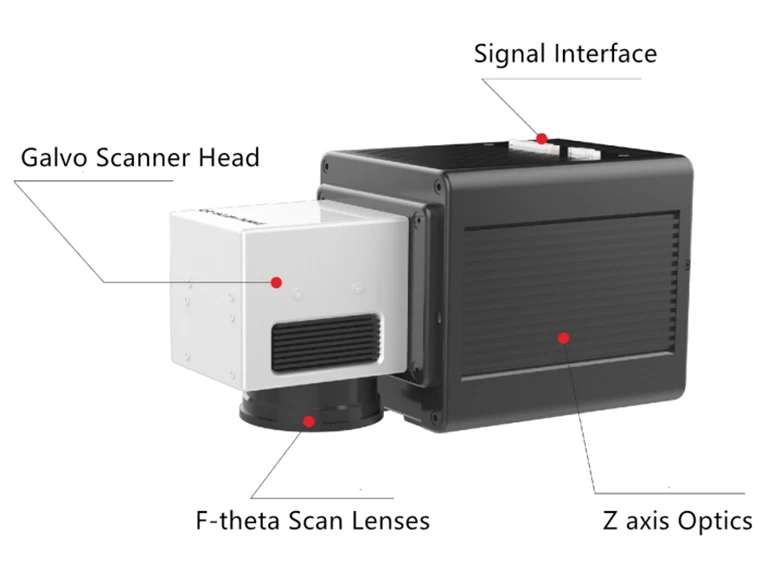

china 3D Galvo scanner factory price

3. Scanning for installation, interior decoration, BIM and other buildings

For building construction, installation, decoration and completion acceptance, the 3D laser scanner can run through the entire life cycle of the building to record and control all aspects of the construction. The post-processing software can be seamlessly combined with BIM, and the project can be tracked and understood without the need to be on the construction site Circumstances, to ensure the quality of the project, thereby avoiding the cost of repetitive labor and the delay of the construction period.

Carmanhaas offer 3D scanning system includes multiple pieces of lenses, at least one movable lens will move during process, and the rest lens are used for focusing. The movable lens make the focus change to match the actual focusing length with different laser focusing location on the work place. It can ensure the laser always work with the real focus point on the work place. So it can make the focusing spot size alignment and uniformity.