- Browse Categories

- CO2 Laser Cutting

- Fiber Laser Cutting

- Laser Marking & Engraving

- Fiber Laser Welding

- Marking & Welding Machine

- Additive Manufacturing System

- Laser Etching System

- Ultra-fast Laser Processing

- Laser Cleaning System

- Subscribe

-

Get email updates on new products

- Certifications

-

- Laser Marking & Welding Machine

- Contact Us

-

Suzhou Carman Haas Laser Technology Co., Ltd

Address: No 155, West Road Suhong, Suzhou Industrial Park, Suzhou City, Jiangsu , P.R. China

Tel: +86-18211675110

Fax: +86-512-67678768

E-mail:wangxin@carmanhaas.com

https://www.carmanhaaslaser.com Contact Now

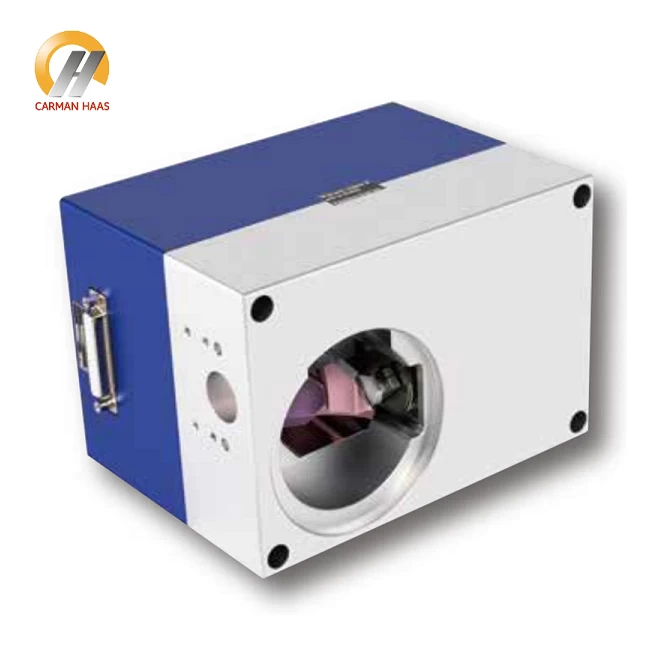

SLM Laser Lenses On Sale Factory

- Brand Name: CARMAN HAAS

- Wavelength: 1030-1090nm

- Application: Aerospace/Mould

- Power: 200-1000W Single Mode Laser

- Main Parts: QBH Optical Module, Galvo Scanner, F-Theta Lenses, Protective Window

- Place of Origin: Jiangsu, China (Mainland)

- Delivery time: within 24 hours after receiving payment

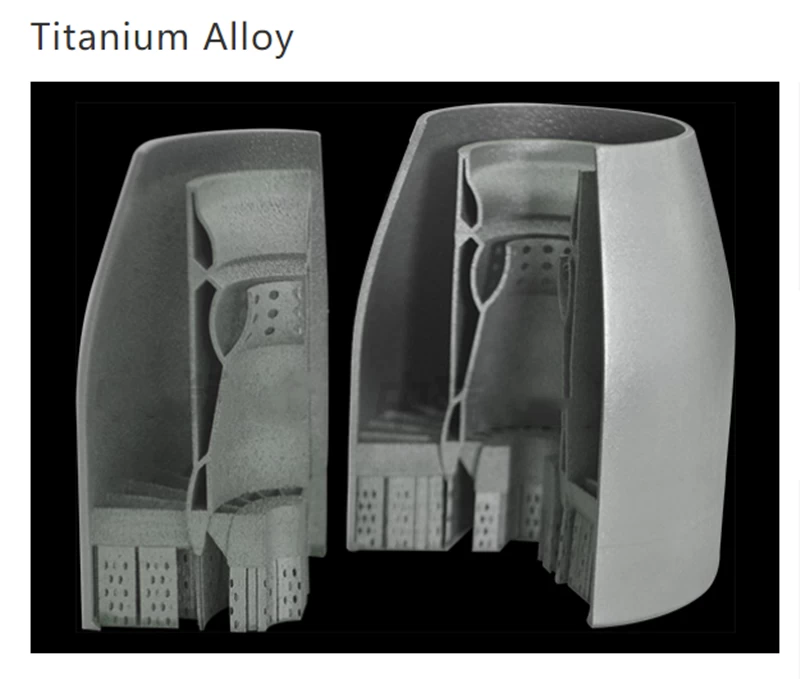

CARMAN HAAS SLM laser lenses on sales, Laser metal 3D printing technology mainly includes SLM (laser selective melting technology) and LENS (laser engineering net shaping technology), among which SLM technology is the mainstream technology currently used. This technology uses laser to melt each layer of powder and produce adhesion between different layers. In conclusion, this process loops layer by layer until the entire object is formed. SLM technology overcomes the troubles in the process of manufacturing complex-shaped metal parts with traditional technology. It can directly form almost completely dense metal parts with good mechanical properties, and the precision and mechanical properties of the formed parts are excellent.

CARMANHAAS Compared with the low precision of traditional 3D printing (no light is needed), laser 3D printing is better in shaping effect and precision control. The materials used in laser 3D printing are mainly divided into metals and non-metals。Metal 3D printing is known as the vane of the development of the 3D printing industry. The development of the 3D printing industry largely depends on the development of the metal printing process, and the metal printing process has many advantages that the traditional processing technology (such as CNC) does not have.

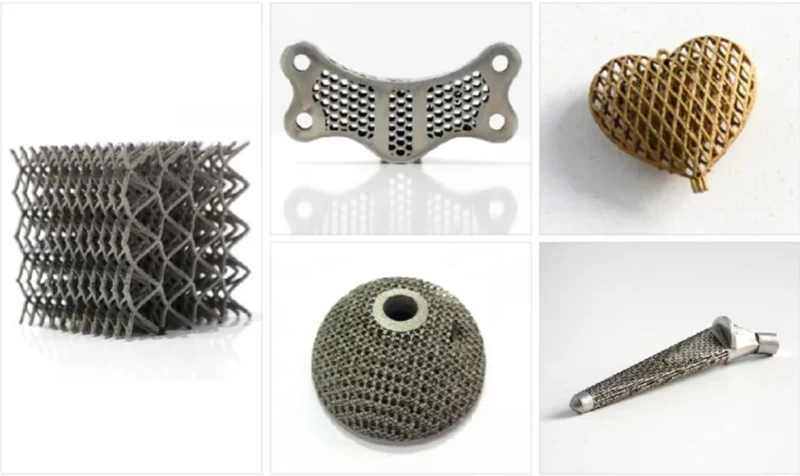

In recent years, CARMANHAAS Laser has also actively explored the application field of metal 3D printing. With years of technical accumulation in the optical field and excellent product quality, it has established stable cooperative relations with many 3D printing equipment manufacturers. (China 3D Galvo scanner factory price ) The single-mode 200-500W 3D printing laser optical system solution launched by the 3D printing industry has also been unanimously recognized by the market and end users. It is currently mainly used in auto parts, aerospace (engine), military products, medical equipment, dentistry, etc.

1. One-time molding: Any complicated structure can be printed and formed at one time without welding;

2. There are many materials to choose from: titanium alloy, cobalt-chromium alloy, stainless steel, gold, silver and other materials are available;

3. Optimize product design. It is possible to manufacture metal structural parts that cannot be manufactured by traditional methods, such as replacing the original solid body with a complex and reasonable structure, so that the weight of the finished product is lower, but the mechanical properties are better;

4. Efficient, time-saving and low cost. No machining and molds are required, and parts of any shape are directly generated from computer graphics data, which greatly shortens the product development cycle, improves productivity and reduces production costs.

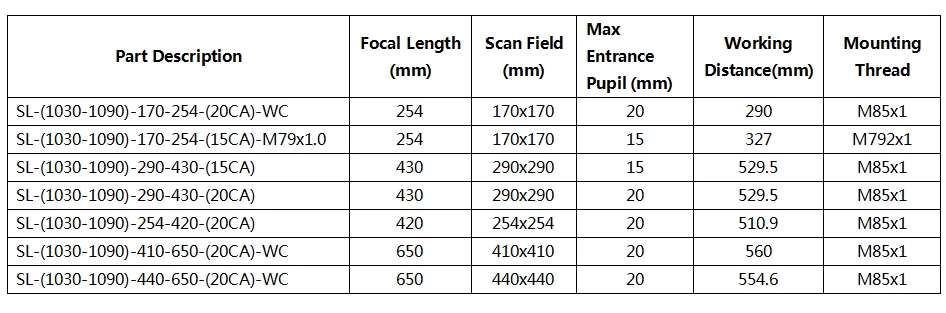

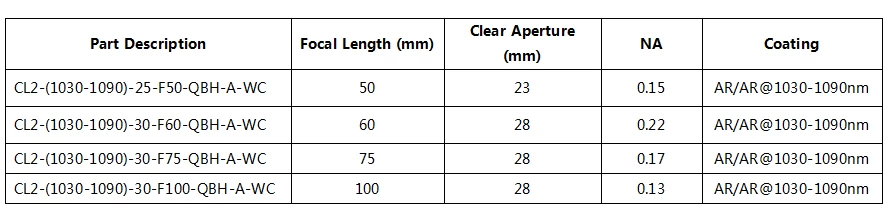

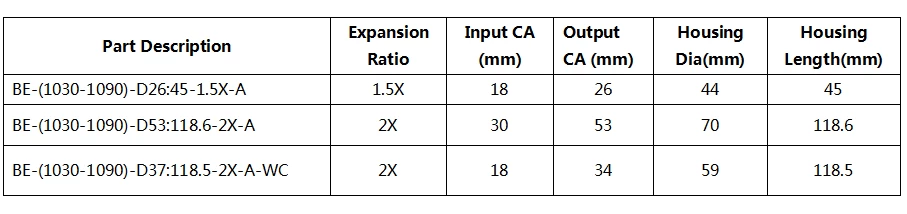

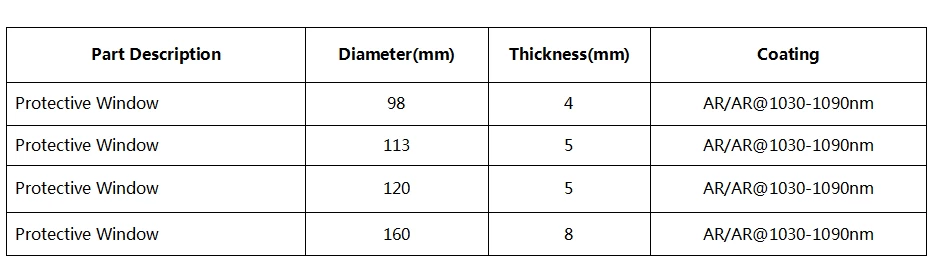

Technical Parameters:

1030-1090nm F-Theta Lenses

1030-1090nm QBH Collimating Optical Module

1030-1090nm Beam Expander

1030-1090nm Protective Window

Factory

Certificate&Exhibition

Packing List

Return Policy:

Should returns be required:

Step 1) Contact us with this website email.

Step 2) Provide as much detail as possible about the problem you are having.

Step 3) Authorization to return the item will be issued.

Step 4) Return the item for the agreed replacement or refund.

Logistics:

(1)For Laser Optics order delivery,can be optional with DHL,UPS,FedEx,TNT,EMS,ets

(2)For Laser machine order delivery,can be optional with terms of EXWork FOB,CNF,CIF By Air or by Sea based on the buyer's forwarders or ours.

FAQ

Q1.Are you a manufacturer?

A1: Yes, we are professional and experienced manufacturer with our own molds and production lines.

Q2.How about quality of products?

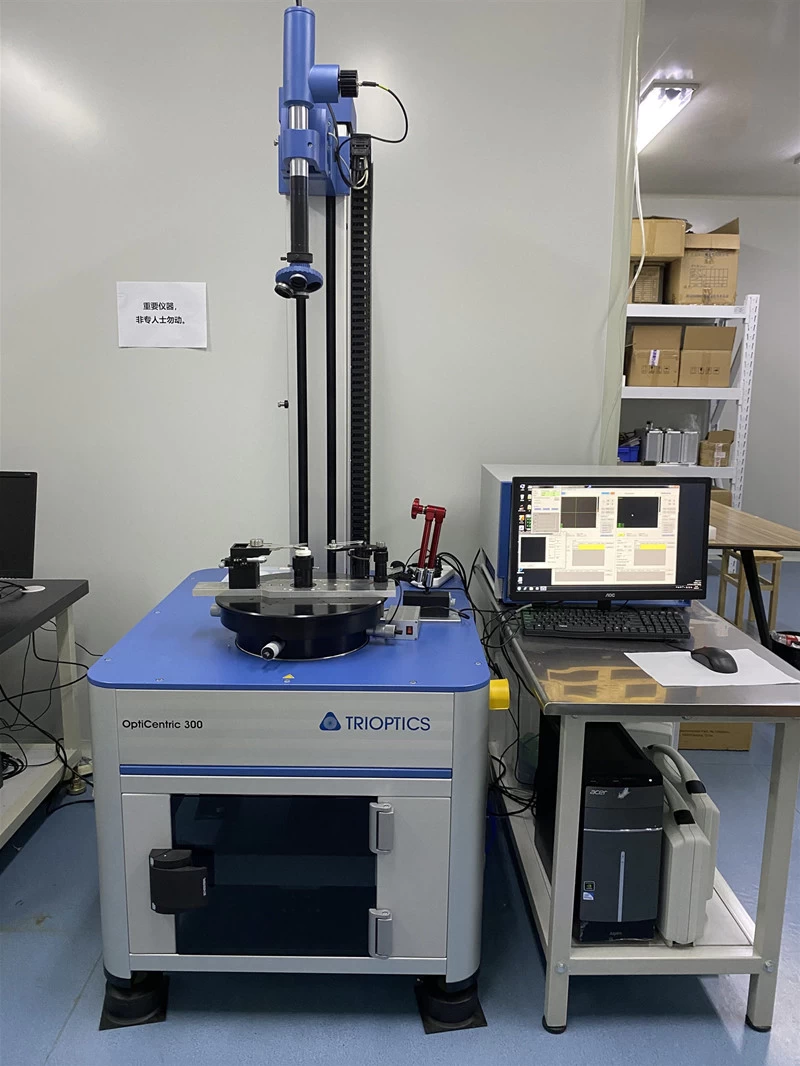

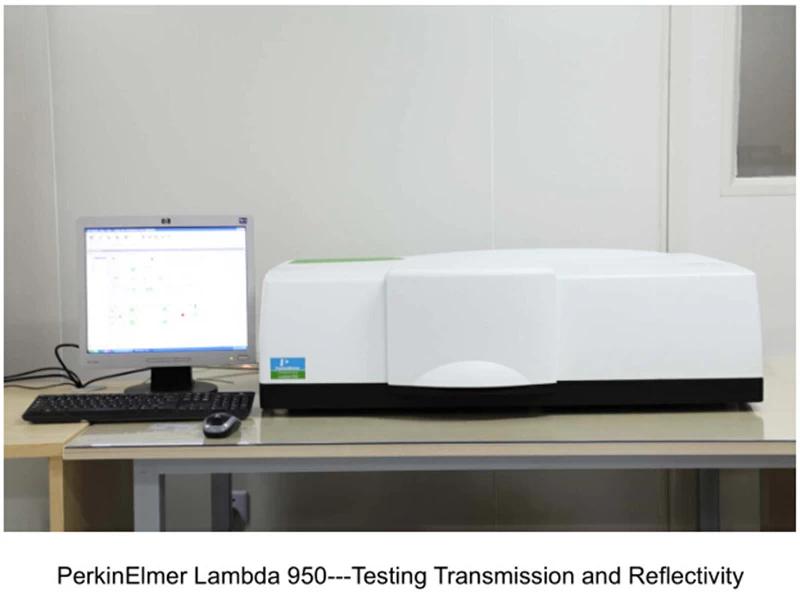

A2: Our technicians and QC teams test the products one by one using aging line, professional devices and instruments to ensure the quality for all products.

Q3.How about price?

A3: We are a manufacturer and always offer our customers the most competitive prices.

Q4.How to place an order?

A4: Contact with online service, or sent email to us directly, we will reply to you with product price, specifications, packing etc. soon. Thank you.

Q5.May I send material to test marking performance?

A5: Yes! You are welcome to send material to test our superior quality and service.

Q6.Can I visit your factory?

A6: Yes, welcome to visit our factory at your convenient time.

Q7.How can I make OEM or ODM orders?

A7: We have different print processing for different OEM/ODM orders. Please contact us with online service or send email to us directly.

Q8. How should I pay for my orders?

A8: You can pay by T/T would be available for qualified bank and MOQ required for each order.

Tel:+86-18211675110

Wechat:wx136241032

Contact Person:John Wang

PDF Show:PDF

-Optical-System-for-3D-Printing-and-Additive-manufacturing-Processing.jpg.webp)