How to maintain the hand-held fiber optic welding machine daily?

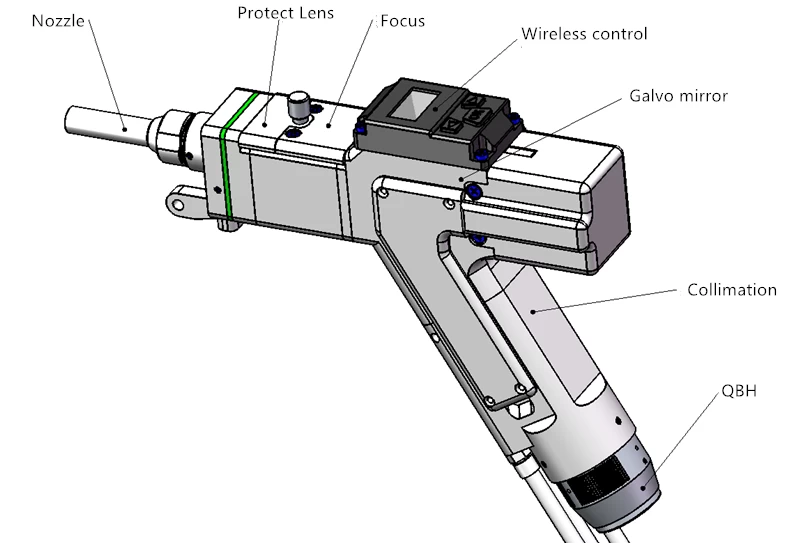

Hand-held laser head is light and portable, it can weld any part of the workpiece, and has various welding methods such as butt welding, stack welding, tailored welding. With the continuous improvement of the process, the requirements for hand-held fiber optic welding machines also increase rapidly. Today we discuss the daily maintenance steps of the handheld fiber optic welding machine:

portable welding machine manufacturer

There are many types of laser welding machines, such as optical communication laser welding machines, optical fiber transmission laser welding machines, galvanometer laser welding machines, hand-held laser welding machines, etc.

In order to ensure that the laser has always been in a normal working state, after two weeks of continuous operation or when it is stopped for a period of time, the components in the optical path such as the laser module, dielectric diaphragm and lens protection glass should be checked first before starting the machine to ensure that each optical component has no Abnormal phenomena such as dust pollution and mildew should be dealt with in time to ensure that the optical components will not be damaged under strong laser irradiation. (If the equipment is used in a relatively clean environment, the above inspection can be extended to one month or even longer.)

Equipment operators can often check the laser output spot with black image paper. Once the uneven spot or energy drop is found, the resonator of the laser should be adjusted in time to ensure the beam quality of the laser output.

Welding f theta Lenses Factory China

The purity of the cooling water is the key to ensure the laser output efficiency and the life of the laser concentrating cavity components. During use, the conductivity of the inner circulating water should be checked once a week to ensure its conductivity is 30.5MW·cm. The inner circulating water must be replaced once a month. For deionized water, the conductivity of newly injected pure water must be 32MW·cm. Pay attention to the color change of the ion exchange column in the cooling system at any time. Once it is found that the color of the resin in the exchange column becomes dark brown or even black, the resin should be replaced immediately.