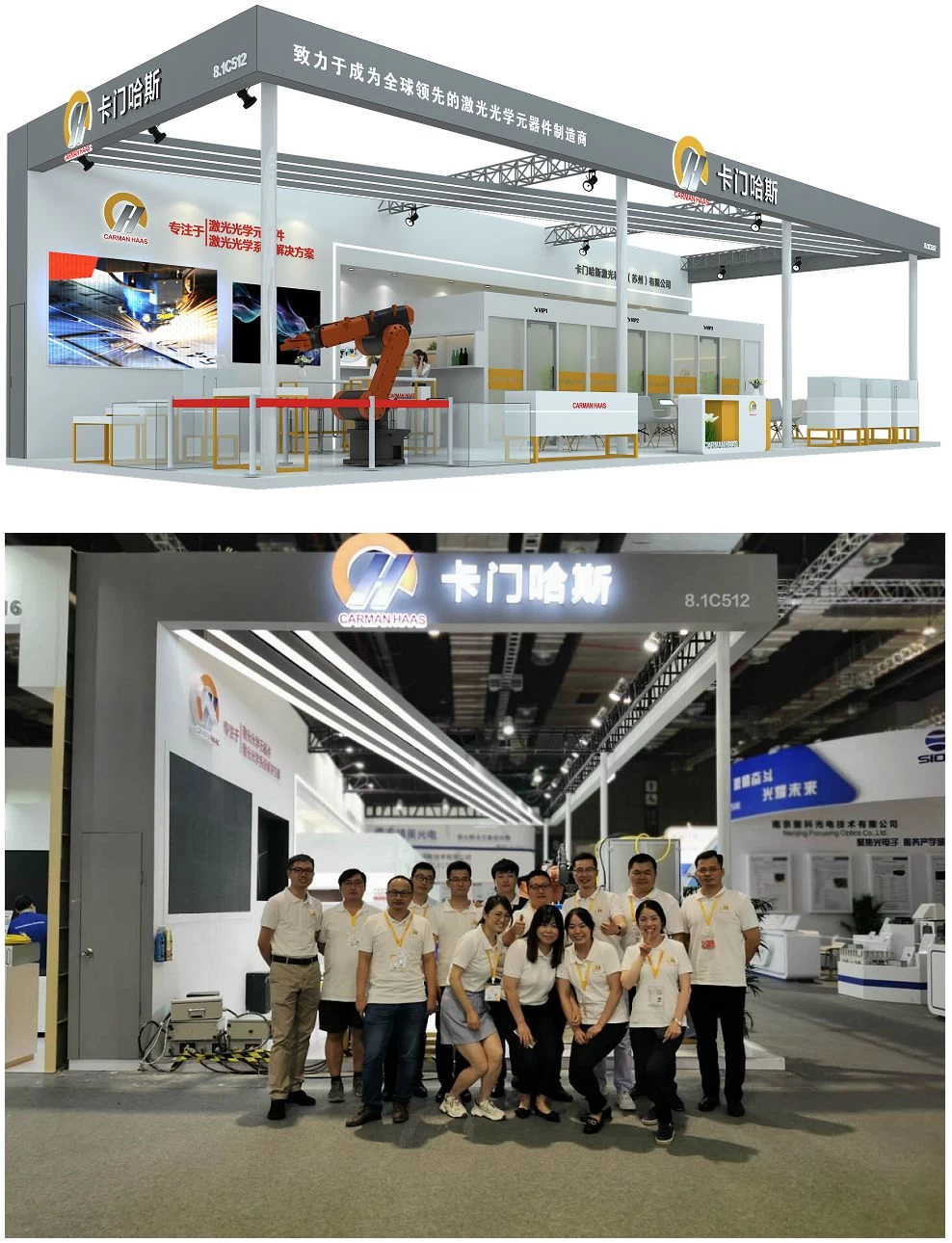

2020 Laser World of Photonics Shanghai

From July 3rd to 5th, 2020, the Laser World of Photonics Shanghai is held at the Shanghai National Convention and Exhibition Center.

Domestic and foreign experts, manufacturers, and practitioners from the laser, optoelectronics, and optical industries gathered here to focus on the five major sections covering laser and optoelectronics, optical and optical manufacturing, laser production and processing technology, imaging and machine vision, inspection and quality control Comprehensive product content, exchange the most advanced optoelectronic science and technology, and focus on the development of China's optoelectronic industry.

This exhibition brings together many well-known laser companies, such as TRUMPF, Han's Laser, IPG, HSG Laser, Coherent, Raycus Laser, JPT Laser, N-light laser, TETE Laser, UW Laser etc.

Carmen Haas Laser launched many optical components and complete optical systems at this exhibition: swing welding head, UV Telecentric lens, Bessel cutting head, 6000W galvanometer welding laser optical system, 3D dynamic scanning laser optical system, high power Laser cleaning optical system, photovoltaic cell laser scribing optical system, plastic laser welding optical system, etc.

The high-power galvanometer welding system and welding seam tracking solution independently developed by Carmen Haas Laser has a strong advantage in high-power welding applications. It is a welding system that can replace foreign brands. The welding head adopts motor-driven X and Y-axis vibrating lenses, with multiple swing modes, and swing welding allows workpieces to have irregular welding, larger gaps and other processing parameters can significantly improve the welding quality; the internal structure of the welding head is completely sealed to avoid optics Part of it is contaminated by dust; equipped with air knife and coaxial blowing to reduce the pollution of welding fumes and splashing residue on the lens; the lens is protected by a pump type structure, which is easy to replace.

Since the overseas epidemic situation has not completely subsided, my country's foreign personnel are still not open to entry, so this year's exhibition has reduced the number of foreign exhibitors, but local laser companies and foreign companies have all made their appearances in China. This is the first exhibition in the laser and optoelectronic industry after the epidemic, which means that my country's laser industry has fully recovered.