3D printing: What is SLA technology?

As one of the 3D printing molding methods, SLA has been accepted by the public due to its diversified materials and low price. It has been widely used in many fields. Today, the editor will take you to understand what is the SLA process?

1. Process overview

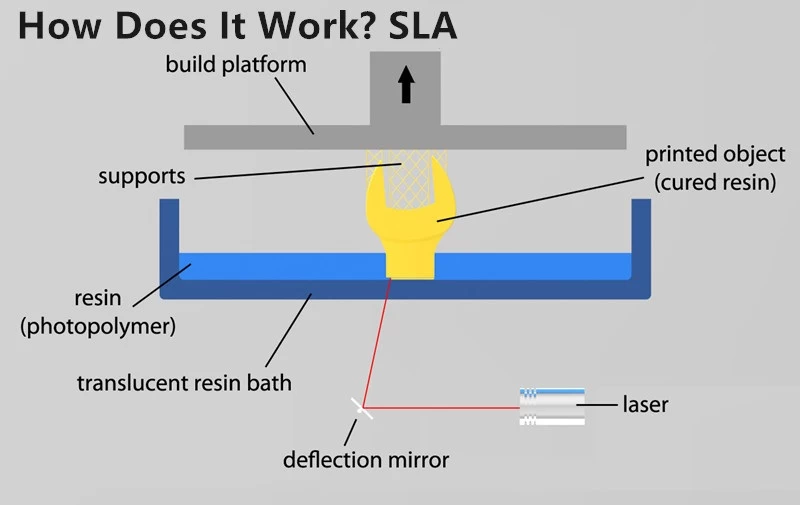

SLA, the full name of stereo light curing molding, is a molding method in which liquid photosensitive resin is irradiated with ultraviolet light of a specific wavelength and intensity to cause polymerization to solidify layer by layer and generate a three-dimensional entity.

Stereolithography 3D SLA 3D Printer for UV Laser Additive manufacturing Processing(China 3D Printer Optical System Manufacturer)

2. Process principle

SLA uses ultraviolet rays to irradiate the liquid photosensitive resin to solidify. During the processing, the platform will sink into the resin tank layer by layer. The resin tank is filled with liquid resin. The ultraviolet light is irradiated on the liquid surface under the action of the deflecting galvanometer, and the information is based on the cross-sectional profile. Scan, where the light spot passes, the irradiated liquid will solidify, and a plane scan will process a layer corresponding to the layered plane pattern, and firmly bond with the solidified part of the previous layer, and repeat until the whole The workpiece is complete.

F-Theta Scan Lens For 3D Printing SLM SLS SLA Optical system supplier

The use of the SLA process generally requires cleaning, de-supporting, polishing, and re-curing treatments to obtain products that meet the requirements. The SLA process needs to add support to the cantilever part, and the product and support are made of the same material. For color models, post-color processing is also required.

3. Process advantages

(1) High precision, smooth surface, large size products can be produced;

(2) Good rigidity, excellent acute angle, small shrinkage;

(3) The surface details are excellent, the texture is very high, and the production speed is relatively fast;

(4) There are many types of resins (white, translucent, fully transparent, high toughness, etc.) to meet various performance requirements.

3D Printing and Additive Manufacturing Optical Lenses for SLM/SLS/SLA (SLA Optical system supplier china)

4. Scope of application

(1) Quickly process high-precision, high-surface quality, multi-detail prototypes, which can be used in automotive molds, medical biology, consumer electronics, game animation, architectural design, sculpture modeling, home decoration and other fields. Concept models, general components, appearance verification , Assembly check, in some cases can be used for functional testing.

(2) There are corresponding characteristic materials for special requirements, such as heat-resistant resin and fully transparent resin.