Application of UV Laser Processing

UV lasers are famous for high precision processing and become one of the mainstream lasers after fiber lasers.

Why can UV lasers be quickly applied in various laser micro-processing fields?

What are its advantages in the market?

What are the unique attributes in industrial laser micro-processing applications?

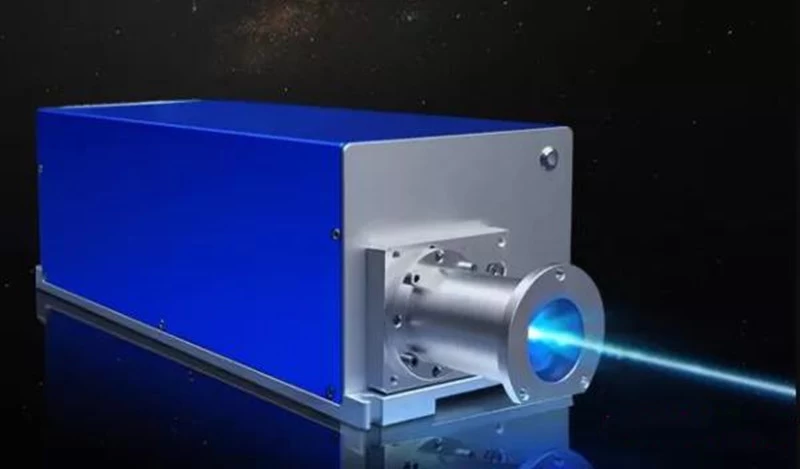

Solid-state UV Laser

Solid-state UV Lasers are classified into xenon lamp-pumped UV lasers, krypton lamp-pumped UV lasers, and new laser diode-pumped all-solid-state lasers according to pumping methods. Generally adopts integrated design, which has the characteristics of small spot, high repetition frequency, reliable performance, strong heat dissipation capacity, good beam quality and stable power.

“Cold” + precision machining

UV Lasers have unique properties, which are called "cold" processing. Lasers with shorter wavelengths and pulse widths and lower M2 (beam quality) can create a more focused spot and maintain the smallest heat-affected zone (HAZ), in the marking application, it can keep the object as it is to the greatest extent and reduce the damage during processing. Such as glass marking, ceramic carving, glass perforation, flexible circuit board cutting and other applications, it is very popular among processing companies.

UV Laser is a kind of light invisible to the naked eye. It has a small spot (0.07mm), narrow pulse width, fast speed, and high peak output. The high-energy laser is used to locally irradiate the workpiece to vaporize the surface material or change the color. The photochemical reaction leaves a permanent mark. High power, high pulse repetition frequency (PRF), pulse shaping and pulse splitting can all contribute to improving the productivity of micromachining。

355 Galvo Scanner Price China,Optical Lens for UV Laser Processing

(1)Characteristics of Camanhaas UV Lens

High precision, small assembly error: < 0.05mm;

High transmittance: >/=99.8%;

High damage threshold: 10GW/cm2;

Good stability.

(2)Advantage of Camanhaas UV Lens

Large format Telecentric Scan Lens, Maximum Area: 175mm x175mm;

Large aperture incident spot design, compatible with different galvanometer configurations;

Large-diameter Fixed Beam Expander and Variable beam expander,

compatible with various spot size requirements;

High quality, high reflectivity optics that minimize beam quality and

laser energy loss.

UV Laser Market Development

In daily life, we will come into contact with a variety of trademark signs, including metal or non-metal, some with text and some with patterns, such as the logo and production date of the electric appliance, mobile phone, keyboard keys, the keys of the mobile phone, and the cup graphic, etc. Many of these marks are currently realized by UV laser marking. The reason is UV laser marking is fast and without consumables. Through optical principles, permanent marks can be printed on the surface of various substances, which is of great help to anti-counterfeiting.

With the rapid development of technology and the arrival of the 5G era, especially the rapid development of the 3C industry, the product update speed is fast, the requirements for equipment manufacturing are getting higher and higher, the speed is getting faster, the weight is getting lighter, the price is affordable, the processing field is becoming more and more extensive, and at the same time becoming more complex, resulting in the manufacturing of parts and components to small And precision development.

Application fields of UV laser

UN Laser has the advantages that other lasers do not have. It can limit the thermal stress, reduce the damage to the workpiece during processing, and maintain the integrity of the workpiece. At present, UV lasers are used in the processing field, and there are four main areas: glass craft, ceramic craft, plastic craft, cutting craft.

1、Glass Marking:

Glass marking can be applied to glass bottle packaging in various industries such as wine bottles, seasoning bottles, beverage bottles, etc. It can also be used for glass craft gift manufacturing, crystal marking, etc.

2、Laser Cutting:

Camanhaas UV F-theta lens factory China,UV Laser equipment can be used in many fields in flexible board production, including FPC profile cutting, contour cutting, drilling, cover film opening window, soft and hard board uncovering and trimming, mobile phone case cutting, PCB shape cutting and many more

3、Plastic Marking:

Applications include most general-purpose plastics and some engineering plastics, such as PP,PE,PBT,PET,PA,ABS,POM,PS,PC,PUS,EVA etc,It can also be used for plastic alloys such as PC/ABS and other materials. The laser marking is clear and bright, and it can mark black and white writing.

4、Ceramic Marking:

Applications include tableware ceramics, vase ceramics, building supplies, ceramic sanitary ware, tea set ceramics, etc. UV Laser ceramic marking has high peak value and low thermal effect. It has natural advantages for similar ceramic fragile products, such as etching, engraving, and cutting that are not easy