What accessories does the laser welding machine include?

1. Workbench: used to fix work and ensure the relative position of the workpiece and the laser beam during processing. According to the processing requirements, the worktable can drive the workpiece to make the required relative movement.

2. Laser welding machine control system: used to control the relative movement between the laser beam and the workpiece, and adjust the working parameters of the whole machine to ensure the safe and reliable operation of the whole machine. Therefore, the control system is the core of the normal operation of the laser welding machine.

China Handheld Welding Manufacturer

3. Laser: It is a device that uses the principle of stimulated radiation to amplify or oscillate light in some excited substances, and can emit laser light. The laser is the core part of the laser equipment, and the requirements for the laser are stable, reliable, and able to operate normally for a long time.

4. Cooling system: When the laser welding machine is working, most of the input energy of the pump source to the laser is converted into the heat energy of the lamp, the working substance, and the condenser cavity. When the temperature of the working material is too high, it will seriously damage the normal operation of the laser. Therefore, cooling measures must be taken. Generally, a closed-loop cooling system is used, including liquid pumps, heat exchangers, and containers.

Galvo Head Laser Welding Factory China

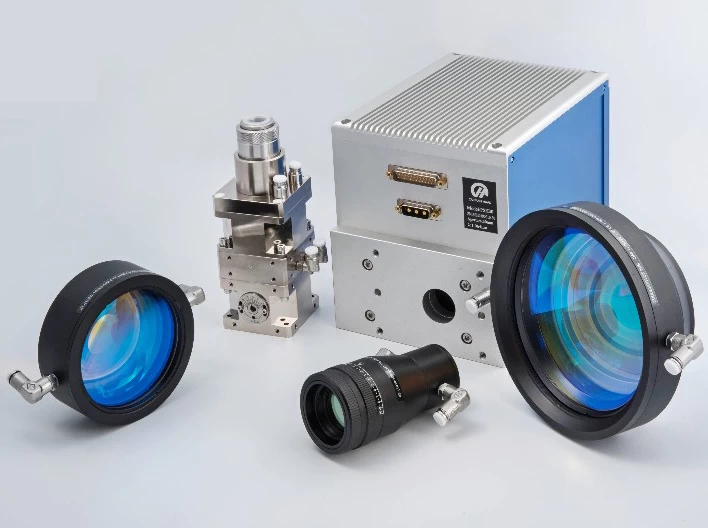

5. Light guide and focusing system: The light guide focusing system is composed of a circular polarizer, a beam expander, a mirror or an optical fiber, and a focusing mirror, etc., which realize the functions of changing the polarization state, direction, transmission and focusing of the beam. The condition of these optical parts has an extremely important influence on the quality of laser welding. Under the action of high-power laser, the performance of optical components, especially the lens, will be deteriorated, the transmittance will be reduced, the thermal lens effect will be generated, and the surface pollution will also increase the transmission loss.

The laser welding machine performs deposition, sealing, repairing and repairing functions for the wear, scratches, pinholes, cracks, defect deformation, hardness reduction, sand holes and other defects of molds and metal workpieces. After the repair, the matrix will not be deformed, annealed, undercut, or residual stress, and will not change its metal structure. The repair accuracy is high. The coating thickness is from a few microns to a few millimeters, and only needs to be polished. High-power argon protection can work for a long time. The energy of the laser beam is adjustable, the moving speed is adjustable, and various welding processes are possible. Laser welding has a high degree of automation and can be controlled by a computer. The welding speed is fast and the efficiency is high. It can conveniently carry out welding of any complex shape.