What are the advantages of laser transparent ceramics?

(1) It has similar physical and chemical properties, spectral characteristics and laser performance to single crystals. Existing studies have shown that high optical quality polycrystalline ceramics are almost the same as single crystals of the same composition in terms of thermal conductivity, expansion coefficient, absorption and emission spectra, and fluorescence lifetime. The laser performance is similar or even better than single crystals. In terms of mechanical properties, polycrystalline ceramics also have a certain degree of improvement over single crystals.

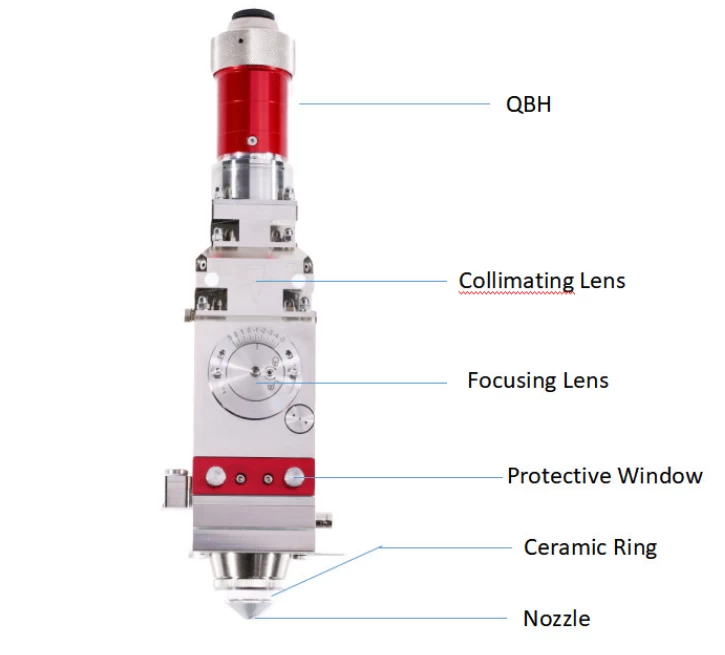

Raytool head window supplier China

(2) It is easy to prepare large-sized laser transparent ceramics, and the shape is easy to control. Crystal growth technology is difficult to obtain large-size single crystals due to various conditions, and it is difficult to meet the needs of special applications. The ceramic molding process is simple, and the sintering temperature is usually much lower than the melting temperature of single crystal growth; some theoretically expected materials with better laser performance, such as: Nd3+/Yb3+:RE2O3(RE=Y, Sc, Lu), etc. Due to high temperature and phase transition near the melting point, it is impossible to grow single crystals with high optical quality and large size at the same time. However, the preparation technology of ceramics is expected to achieve transparency at a temperature far below the melting point.

(3) Short preparation cycle and low production cost. The ceramic material has a simple sintering process and a preparation period of several days, which is suitable for large-scale production and has low cost. The single crystal growth technology is strong, the growth cycle is tens of days, usually requires expensive platinum or iridium crucibles, and the production cost is high.

(4) High-concentration doping can be achieved, with good optical uniformity. Due to the limitation of the segregation coefficient of doped ions in the matrix (for example, the segregation coefficient of Nd3+ ions in YAG crystal is only 0.18), it is difficult to achieve high concentration doping using melt growth technology, and it is easy to form a concentration in the radial direction. Gradient, and form a strain pattern. Since ceramic materials are not limited by the segregation effect, high concentration and uniform doping can be achieved.

(5) Multilayer and multifunctional laser transparent ceramics can be prepared. Ceramic preparation technology can combine materials with different components and functions, which provides greater freedom for laser system design. For example, combining Nd:YAG and Cr4+:YAG together to form a passive Q-switch, or even a combination of Q-switching and Raman laser, which is almost impossible for single crystal materials. The self-Q-switched laser output can also be generated on the same laser transparent ceramic to realize the high efficiency, high power, integration and miniaturization of LD-pumped solid-state Q-switched lasers.

Precitec laser cutting head protective lens window

Compared with laser glass materials (taking neodymium glass as an example), transparent ceramic laser materials (taking Nd:YAG transparent ceramic as an example) have high thermal conductivity, which is conducive to heat dissipation; it has a high melting point and can withstand higher radiation power ; Good monochromaticity; can achieve continuous laser output.

Science and technology have been advancing. I believe that with the expansion and deepening of the research scope of laser ceramics, there will be more and more laser ceramic materials that are better than the predecessors, and finally solid lasers will be more widely used.