What are the steps involved in the pre-processing of metal 3D printing?

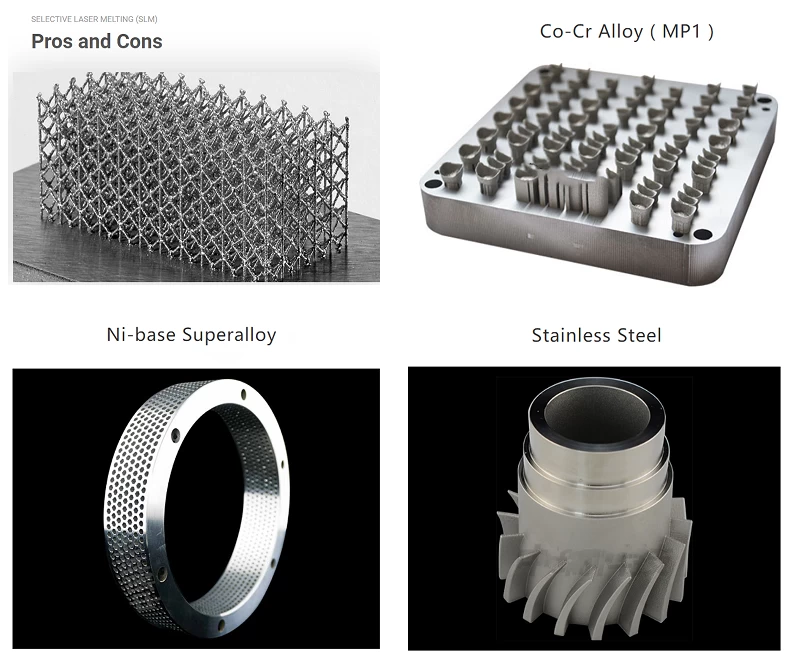

The pre-processing of 3D printing is mainly modeled in the computer, and the design is optimized according to the actual situation of the printer, cutting, placing the appropriate position, then adding support, slicing, and finally printing. 3D printing technology includes FDM, SLA, sls, slm and other different types. The process difficulty and design requirements are also different. There are also different process plans for different materials. Today CARMAN HAAS introduces the metal 3D printing process:

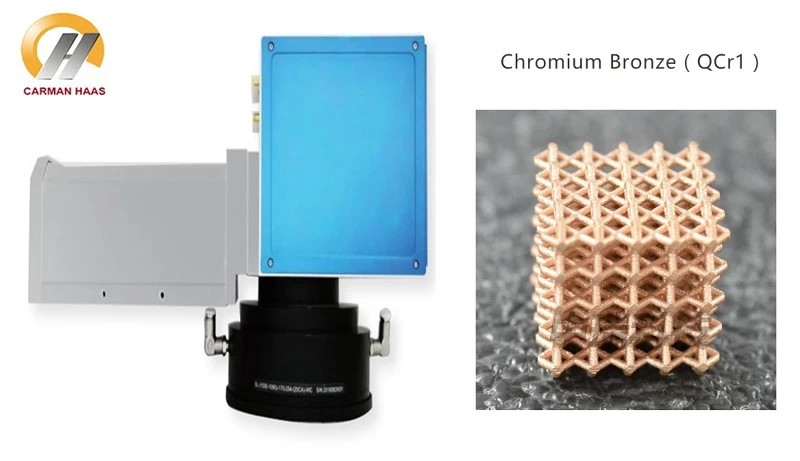

3D Printing and Additive Manufacturing Optical Lenses manufacturer for SLM (CARMAN HAAS SLM Laser Lenses on Sales)

With the decline in the price of metal 3D printing and the improvement in performance, metal 3D printing is accepted by more and more customers. 3D printing metal materials are printed by SLM process, which is a selective laser melting molding process. The pre-treatment process flow of metal 3D printing is How is it?

01. Cleaning the powder in the forming cylinder: sweep the powder in the cylinder into the powder receiving box with a brush.

02. Replacing the squeegee strip: In order to avoid the abrasion of the squeegee strip from affecting the quality of the printed parts, a new squeegee strip should be replaced almost every time after printing.

03. Adjust the substrate: Before printing, you need to adjust the screws at the four corners of the substrate to make the substrate in a horizontal state, otherwise it will affect the quality of the print.

China SLM Optical System Manufacturer

04. Sieving powder: The powder in the powder receiving box needs to be sieved to be recycled. The sieving powder can remove the impurities generated by printing and ensure the printing quality.

05. Replacement air: In order to prevent the metal powder from being oxidized, nitrogen must be filled as a protective gas. The replacement process takes about one and a half hours.

06. Add support:

The main functions of the metal 3D printing support are: (1) Connect with the printing platform to resist stress and prevent edge warping; (2) Resist the force of the squeegee and maintain the shape of the part; (3) Conduct heat.

Since the support is also metal, it is more difficult to remove, so the operator will repeatedly adjust the angle to minimize the support. After the preparation work is completed, the supported print is introduced into the machine to start printing.

CARMAN HAAS China SLA Optical system Manufacturer, Modeling itself is a relatively complex task. First, we must clarify the purpose of modeling, the working principle of 3D printing, and model according to the needs, and then optimize the model design according to the principle of 3D printer, and then it is possible to finally print a high-quality model.