Advantages of laser cutting machine in elevator manufacturing

With the emergence of domestic laser cutting machine manufacturers, the habit of only relying on imports has been broken, and the expensive price has also been reduced a lot. Domestic general machine companies and accessory companies have successively purchased laser cutting machines. The elevator manufacturing industry is no exception.

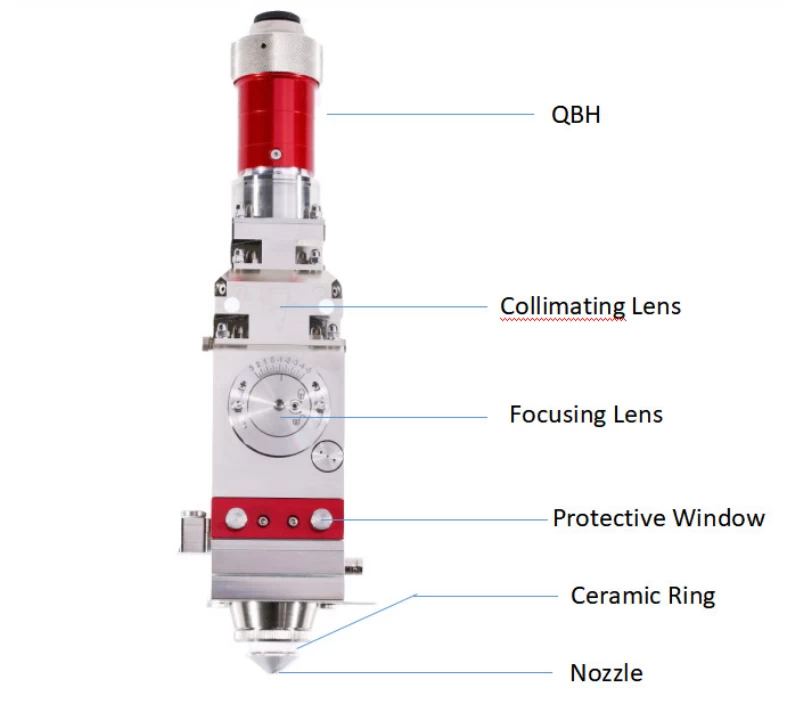

Ospri 1064nm Fiber Laser cutting Head supplier

The main advantages of laser cutting machine in elevator manufacturing are as follows:

1. Short processing cycle

There are many types and small quantities of sheet metal parts in the elevator industry, and many of them need to be determined according to customer requirements. Due to the limitation of tonnage and mold, the processing of multi-station punch presses can not process some sheet metal parts or the long production cycle of molds leads to a longer production cycle, and the programming is relatively complicated, and the requirements for operators are relatively high. Fiber laser The advantages of the flexible processing of the cutting machine are thus brought into play, reducing product development costs.

2. Good cutting effect

There are many stainless steel decorative plates, the surface finish requirements are high, and the processed lines should be smooth and flat, beautiful and beautiful. Multi-station punching machine processing easily affects the surface finish of the plate. The laser processing method has no mechanical stress, which avoids the deformation during the cutting process, improves the elevator quality, upgrades the product grade, and enhances the core competitiveness of the enterprise.

3. High processing flexibility

With the improvement of people's aesthetic level, the fancy styles of products also increase, and the variety of product shapes increases, but the number is not large, and the outline is complex, and ordinary processing methods cannot be realized. Laser cutting is automated and highly intelligent, which can handle various special-shaped workpiece processing, effectively reducing the labor intensity of the operators and optimizing the production process flow.

Fiber laser cutting head protective lens

Using laser cutting technology, the machine has good overall rigidity, stable performance, stable operation, fast speed, fast acceleration, high precision and high processing efficiency. It can meet the cutting needs of carbon steel, stainless steel and other metal plates. It is an ideal choice for the processing of medium and thin plates. It is very suitable for cutting elevator steel plates.