Classification of optical film characteristics

The main optical thin-film devices include reflective film, anti-reflection film, polarizing film, interference filter and beam splitter, etc. They have been widely used in the construction of national economy and national defense, and have received increasing attention from scientific and technical workers. For example, the use of anti-reflection films can reduce the luminous flux loss of complex optical lenses by a factor of ten; the use of mirrors with a high reflection film ratio can double the output power of the laser; the use of optical films can improve the efficiency and efficiency of silicon cells. stability.

The simplest optical film model is a uniform dielectric film with a smooth surface and isotropy. In this case, the optical interference theory can be used to study the optical properties of optical films. When a plane wave of monochromatic light is incident on the optical film, multiple reflections and refractions occur on its two surfaces. The directions of the reflected light and the refracted light are given by the laws of reflection and refraction. The amplitude of the reflected light and the refracted light The size is determined by the Fresnel formula.

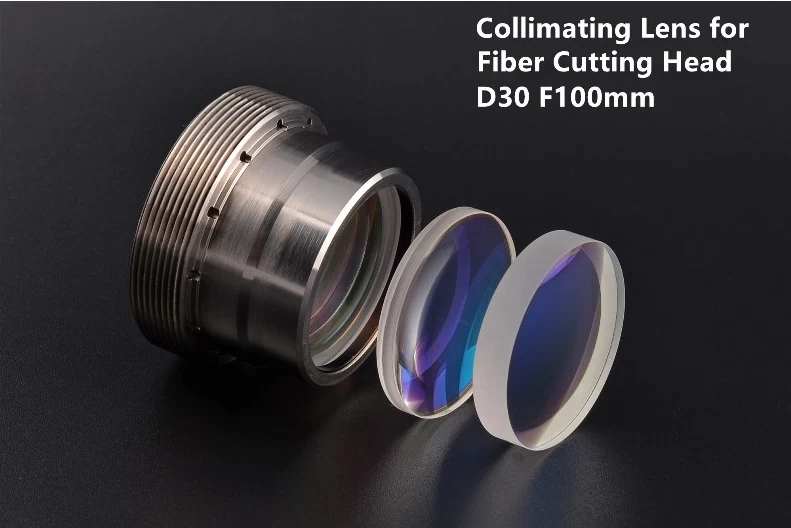

Precitec laser cutting head protective lens window

According to their application classification, characteristics and applications, optical films can be divided into: reflective film, antireflection film/antireflection film, filter, polarizer/polarizer film, compensation film/phase difference plate, alignment film, diffusion film/sheet, Brightening film/prism sheet/condenser, shading film/black and white glue, etc. Related types of derivatives include optical grade protective films and window films.

The characteristics of the optical film are: the surface is smooth, and the interface between the film layers is geometrically divided; the refractive index of the film layer can jump at the interface, but it is continuous within the film layer; it can be a transparent medium or absorption Medium; can be uniformly normal or non-uniformly normal. The actual applied film is much more complicated than the ideal film. This is because: during preparation, the optical and physical properties of the film deviate from the bulk material, and the surface and interface are rough, resulting in diffuse reflection of the light beam; the mutual penetration between the film layers forms a diffusion interface; due to the growth of the film layer , Structure, stress and other reasons, forming various anisotropy of the film; the film layer has a complex time effect.

Reflective films can generally be divided into two categories, one is metal reflective film, and the other is all-dielectric reflective film. In addition, there is a metal dielectric reflective film that combines the two, and its function is to increase the reflectivity of the optical surface.

Generally metals have a large extinction coefficient. When the light beam enters the metal surface from the air, the amplitude of the light entering the metal is rapidly attenuated, so that the light energy entering the metal decreases correspondingly, and the reflected light energy increases. The greater the extinction coefficient, the faster the amplitude of light decay, the less light energy entering the metal, the higher the reflectivity. People always choose metals with larger extinction coefficients and more stable optical properties as metal film materials. The thin metal material commonly used in the ultraviolet region is aluminum, aluminum and silver are commonly used in the visible region, and gold, silver and copper are commonly used in the infrared region. In addition, chromium and platinum are also often used as film materials for some special thin films. Because materials such as aluminum, silver, and copper are easily oxidized in the air to reduce performance, they must be protected with a dielectric film. Commonly used protective film materials include silicon oxide, magnesium fluoride, silicon dioxide, aluminum oxide, etc.

focusing lens for fiber cutting head

The advantage of the metal reflective film is that the preparation process is simple and the working wavelength range is wide; the disadvantage is that the optical loss is large and the reflectance cannot be high. In order to further improve the reflectivity of the metal reflective film, a few dielectric layers with a certain thickness can be plated on the outside of the film to form a metal dielectric reflective film. It should be pointed out that the metal dielectric film increases the reflectivity of a certain wavelength (or a certain wave region), but destroys the characteristics of neutral reflection of the metal film.