Do you really understand laser 3D printing?

Laser additive manufacturing technology, also known as laser 3D printing technology, is an advanced manufacturing technology that integrates optics, materials, machinery, software, and automation control. Due to the limitations of traditional manufacturing methods, there are many complex structural components that cannot be realized, and additive manufacturing provides this possibility. Compared with traditional manufacturing technology, this technology has the characteristics of high flexibility, easy realization of intelligence, and short production cycle. This technology has been widely used in many fields.

However, 3D printing also has problems such as low efficiency and high cost. How to solve it? What are the challenges and opportunities for laser manufacturing?

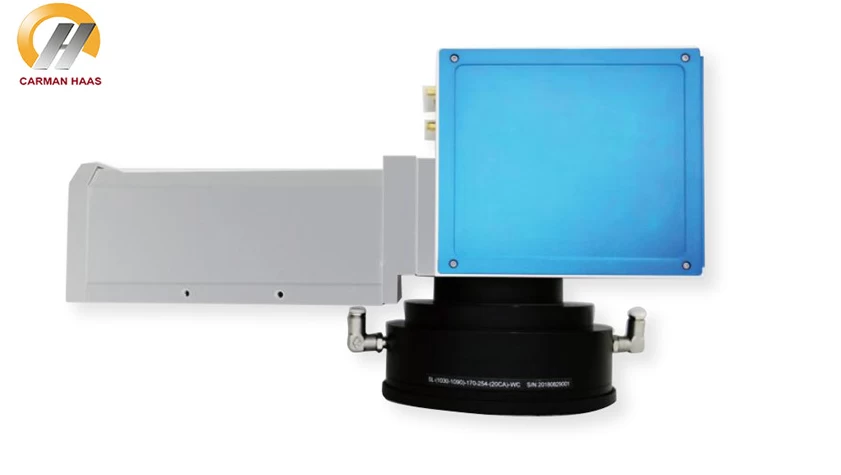

F-Theta Scan Lens For 3D Printing

The background of laser 3D printing

Laser is a kind of artificial light. Compared with incoherent light, it has the advantages of good monochromaticity, good directionality, high brightness, and good coherence. Therefore, lasers are widely used in the fields of environment, information, energy, medical, national security, industrial manufacturing, etc., and it can be said to be ubiquitous.

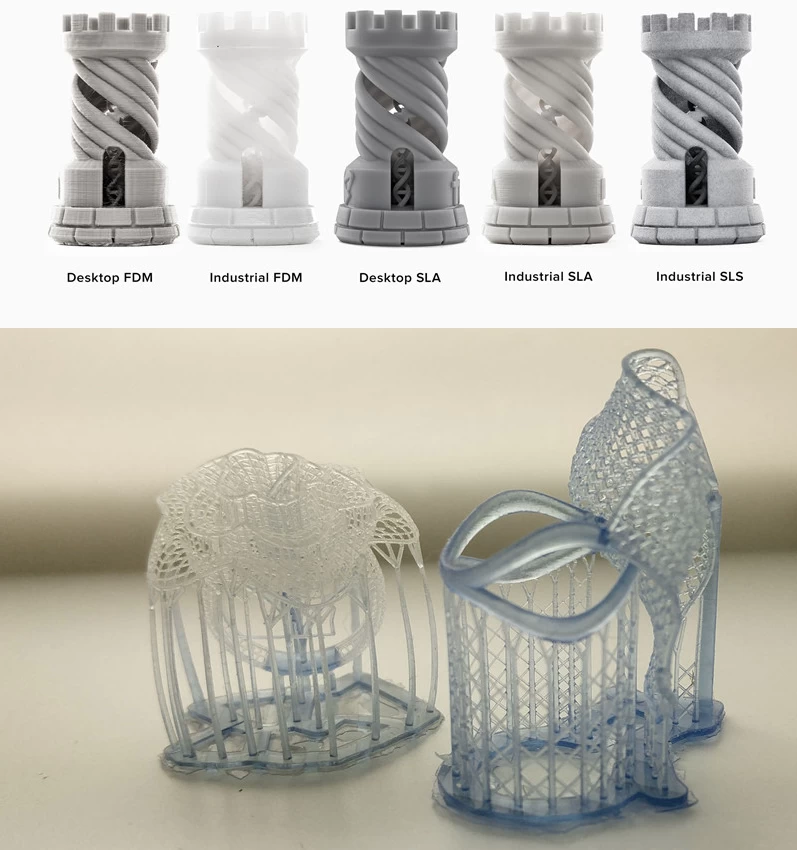

The 3D printing technology pioneered the concept of "additive manufacturing" net shaping. It is a technology that builds three-dimensional objects by bonding powdered metals or plastics layer by layer on the basis of digital model files.

Due to the limitations of traditional manufacturing methods, there are many complex structural components that cannot be realized, and additive manufacturing provides this possibility.Compared with traditional manufacturing technology, this technology has the characteristics of high flexibility, easy realization of intelligence, and short production cycle. This technology has been widely used in many fields.

3D printing is now widely used in industrial manufacturing, aerospace and military fields, as well as biomedical, education, training, consumer products, new materials, construction and other fields.

According to a survey conducted by the China Business Industry Research Institute in 2019, there are more than 400 companies engaged in 3D printing in Guangdong Province alone. There are more and more companies engaged in 3D printing in my country, and competition is fierce.

Problems and solutions of laser 3D printing technology

1. Low efficiency

Solution: Use multiple laser heads, high efficiency, and beam shaping methods.

In response to some low-strength requirements, HP introduced a stereo inkjet 3D printer. In addition, for example, a paper recently published on Science uses digital micromirror devices to output femtosecond lasers at millions of points at the same time, printing layer by layer. It is very fast. It used to take a few hours to play, but now it can be achieved in 8 minutes.

Using static-controlled high-speed jet printing, the printing speed has increased by 3 to 4 orders of magnitude.

2. High cost

Solution: Reduce costs through standardization and modularization of raw materials and equipment parts.

3. Poor surface quality

Solution: Work hard on the selection of materials and processing parameters, and use composite fields, such as adding ultrasound to control the 3D printing process.

In addition, through the combination of adding and subtracting materials, some key parts are relatively rough. After printing, machine processing and then repairing, or 3D printing combined with femtosecond laser processing, the so-called combination of adding and subtracting materials to improve the surface This finish.

China 3D Galvo Scanner Factory Price

4. Small format

Solution: To make a wide format, it is not a simple cavity to enlarge, but also to consider the control system, ventilation system, etc.

5. Few available materials

Solution: Use new materials, composite materials, gradient materials, and multi-materials.

Processing new materials requires certain requirements on lasers, cavities, design, etc. Even the cavity needs to be heated while printing this new material. In addition, it is also discussing how to realize composite materials, gradient materials and multi-material printing.