Who is more advanced in the field of laser processing?

It is said that laser welding, laser cutting, and laser marking together constitute the "troika" of laser processing technology, which is widely used in the industrial field.

Compared with laser cutting and laser marking, laser welding has a relatively short development time, and its process is more difficult than laser cutting and laser marking. Laser cutting and laser marking use laser to destroy the surface structure or overall structure of a substance, while laser welding uses laser to process and melt the structure of the substance and reconstruct it. Compared with simple material structure destruction, material construction has higher requirements on lasers and processing technology.

portable laser welding machine supplier

How is laser welding different from traditional welding technology?

As a modern welding technology, laser welding has deep penetration, fast speed, small deformation, low requirements on the welding environment, high power density, not affected by magnetic fields, not limited to conductive materials, and working conditions that do not require vacuum. The welding process does not produce X-rays and other advantages, and is widely used in high-end precision manufacturing, especially in the new energy vehicle and power battery industries.

Compared with other welding processes, the laser welding process has a strong welding effect. However, compared with other welding processes, the cost of laser welding automation equipment is higher; the equipment precision requirements for welding automation equipment and public construction joints High, difficult to manually operate; high requirements for the properties of the welded material and the accuracy of the fixture.

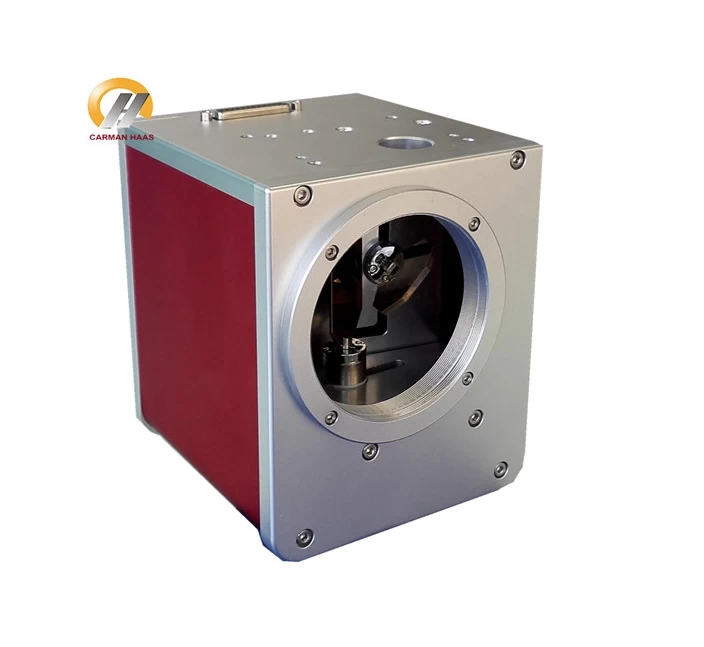

Welding Machine 1000W Handheld Fiber Laser

What are the methods of laser welding?

According to different working principles and adapted to different processing scenarios, laser welding can be divided into five types: heat conduction welding, deep penetration welding, hybrid welding, laser brazing and laser conduction welding.

In terms of product combination, butt welding is required to be as seamless as possible, generally less than 0.05 mm, and the thinner the product, the stricter the requirements. The penetration welding gap requires the upper and lower layers to be tightly bonded as much as possible. The thinner the upper material, the tighter the bonding is required.

portable welding machine manufacturer

The core elements that determine the quality of laser welding are laser energy control and welding process technology.

(1) Laser energy control

Because the material to be welded has different absorption rates for lasers of different wavelengths (which can vary from 5% to 50%), the laser selection is different, and the welding effect is completely different. In order to output a uniform and stable welding laser beam to the weldment, it is necessary for the laser output power to have good consistency or to be able to accurately control the laser output power. Too low power will lead to insufficient welding melting and affect welding quality. Too high power or fluctuations It will cause undesirable effects such as splashes and pores. Therefore, the control of laser energy has become one of the most critical technologies for laser welding.

(2) Welding technology

The action process of laser and substance is more complicated. The effect of laser welding is related to laser wavelength, power density, welding time, welding head angle, focal distance, laser absorption rate and cleanliness of weldment, thickness and thermal conductivity of weldment, protection Dozens of factors such as gas type and flow rate are related. Therefore, laser welding technology is also one of the key factors affecting welding quality. It requires laser welding process technicians to constantly explore and summarize, and long-term experiments can achieve good welding results.