Laser remote welding laser welding technology of white body

Safety, comfort, energy saving and environmental protection have always been the themes of the world's automobile industry. Laser welding technology is particularly valued and widely used in the automotive industry, and automotive panels are one of the five major types of laser welding. Laser welding has become a standard process in the manufacture of body panels! Today, Carmanhaas will introduce to you the laser welding process for remote welding of body-in-white

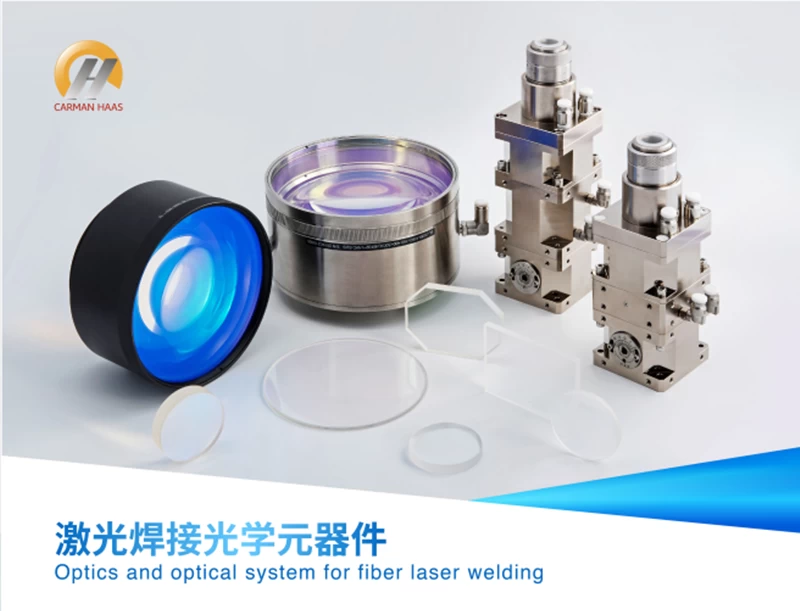

The remote welding is realized with the help of the galvanometer scanning head,The laser beam positioning method is different, The laser beam is incident on the X and Y-axis mirrors of the scanning galvanometer, The computer controls the motor to precisely adjust the angle of the mirror to realize the laser The arbitrary deflection of the beam enables the laser with a certain power density to focus on different positions on the surface of the workpiece to realize the welding function.

Galvo Head Laser Welding Factory China

Advantage

Its positioning accuracy is high, the time is short, the welding speed is higher than the general laser self-fusion welding, the efficiency is higher, the focal length is longer, it will not interfere with the welding fixture, and the optical lens pollution is less; the welding seam of any shape can be customized to optimize the structural strength. Compared with resistance spot welding, laser remote welding technology gives full play to the technical and economic advantages brought by single-sided, non-contact laser welding, and combines it with the advantages of high-speed scanning galvanometers, which greatly shortens the welding time. The overall production efficiency is improved, and it can be effectively used for the welding of an increasing number of automobile panels and parts.

shortcoming

It has relatively high requirements for material and assembly accuracy, mainly due to the accuracy of bonding on both sides of the weld; when the thickness of the workpiece is too large, the aspect ratio of the weld will increase, and the shear strength at the weld will be low. It is mainly suitable for low sheet metal thickness. For 2mm connections, such as car covers, etc.

The application of laser welding to automobiles can reduce body weight, improve body assembly accuracy, increase body stiffness, and reduce stamping and assembly costs in the automobile body manufacturing process. Carmanhaas (Laser Welding Factory China) the specially designed Welding control system can meet the needs of customers in different fields. The control system is highly integrated and equipped with a special safety system, making it safer, more convenient and reliable for customers to use. Welcome with us connect!