Laser thermal lens effect

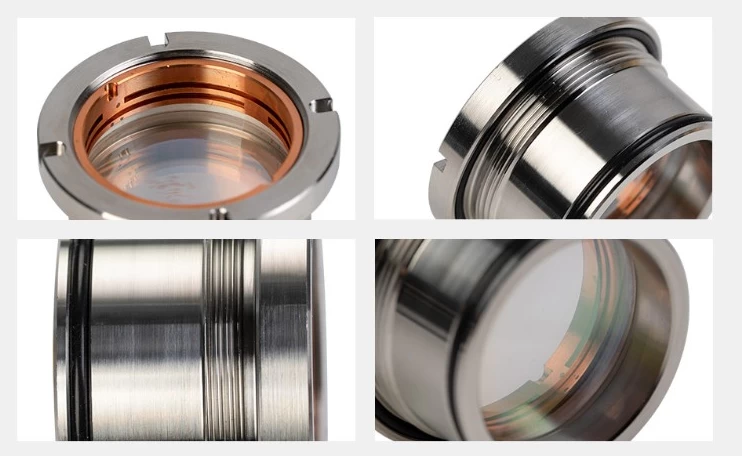

As the application range of fiber lasers in industrial processing continues to expand, high-power fiber lasers are also in greater demand.(Optics lens for fiber laser) In higher power laser applications, a series of new problems will appear, which affect the stability of laser processing, such as thermal lens effects.

1. What is thermal lens effect

China Optics lens for fiber laser,Due to the poor quality of optical components, dirt, damage and other reasons, the absorption rate of the laser increases. After the optical components are exposed to the laser beam for a long time, the temperature rises and thermal deformation occurs, which in turn causes the refractive index and The reflection direction of the reflective optical element changes. The thermal lens effect will change the position of the laser focus (beam waist), thereby affecting the application effect. Since the transmissive optical element has a higher absorption rate of laser light and a greater temperature rise, the thermal lens effect is more obvious.

2. The influence of thermal lens effect in laser applications

Compare the cutting surface at the beginning and the end of the workpiece processed by the laser cutting machine. At the beginning of processing, because the laser beam is irradiated for a short time and the optical element is still in a low temperature state, the influence of the thermal lens effect is relatively small. At the end of the processing when the cutting time requires more than 10s, because the optical element is irradiated by the laser beam for a long time, a thermal lens effect will occur, and the focus position and beam pattern will also change.

3. Harm

Under the condition of high-power operation of solid-state lasers, the distortion of the heat penetrating device (omitted) caused by the temperature gradient distribution inside the gain medium occupies a dominant position. The distortion caused by the thermal lens effect will cause the instability and instability of its output power. The coupling between multiple modes also limits the increase of laser power, which seriously affects the performance of solid-state lasers.

For example, we often see that the light spot diverges, splits, becomes 3, 5, or even a large bug (also called higher-order mode)