The application development trend of laser additive manufacturing technology

Additive manufacturing technology (3D printing) is an important field of laser technology industrialization that has developed rapidly in recent years. With a series of advantages, laser technology has more and more application requirements in the field of advanced manufacturing. Taking 3C electronic products as an example, lighter, thinner, and more portable are the goals that product designers are constantly pursuing. The requirements for high integration and high precision of products are constantly escalating, and this is where laser technology comes in.

With the introduction and implementation of "Made in China 2025" and "Additive Manufacturing Promotion Plan", in recent years, additive manufacturing has rapidly heated up globally and has become one of the hot topics and focuses in the industry. This technology has been widely used in aerospace, The automotive, medical, metal, mold and other industrial fields have become the core processing elements for the rapid transformation of the manufacturing industry to intelligence. In general, the growth of industrialization and the increasing demand for products with complex designs have promoted the rapid development of the global additive manufacturing market.

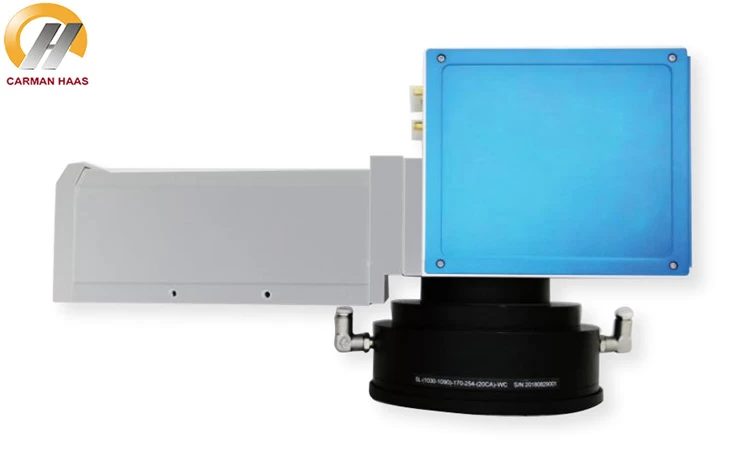

3D Galvo Scanner Head for Engraving

Different technologies can be used to realize additive manufacturing, such as direct writing molding, fused deposition molding, light-cured three-dimensional modeling, electron beam melting, selective thermal sintering (SHS), selective laser sintering (SLS), selective laser melting (SLM) ), direct metal laser sintering, layered solid manufacturing and powder bed method, etc.

At present, the growth of the automotive, manufacturing, aerospace, food and beverage and medical industries is accelerating the fermentation of the global additive manufacturing market. In the future, 3D printing or additive manufacturing technology is expected to provide more applications for the design of parts and finished products.

China 3D Galvo Scanner Factory Price

In the future research and development trends of laser additive manufacturing technology, the following directions deserve further attention:

(1) Laser additive manufacturing material-structure-process integration driven by high-performance/multi-function, and actively realize the high-performance and multi-function of components;

(2) The design, preparation and shaping of "multiphase materials" and "multi-materials" of laser additive manufacturing to achieve "addition of suitable materials to suitable positions";

(3) The innovative structure design of laser additive manufacturing realizes high performance and multi-function of components, to highlight the "unique structure realizes unique functions";

(4) Build key technologies and methods for laser additive manufacturing process simulation, monitoring, feedback, and process optimization for full-scale components and full process flows, and comprehensively improve the technical level, quality, and industrial application level of laser additive manufacturing.