The generation and solution of laser thermal lens effect

As the application range of fiber lasers in industrial processing continues to expand, high-power fiber lasers are also in greater demand. In higher power laser applications, a series of new problems will appear, which affect the stability of laser processing, such as thermal lens effects.

What is thermal lens effect

Due to the poor quality of optical components, dirt, damage, etc., the absorption rate of the laser increases. After the optical components are exposed to the laser beam for a long time, the temperature rises and thermal deformation occurs, which in turn causes the refractive index and The reflection direction of the reflective optical element changes. The thermal lens effect will change the position of the laser focus (beam waist), thereby affecting the application effect.

Since the transmissive optical element has a higher absorption rate of laser light and a greater temperature rise, the thermal lens effect is more obvious. Fiber laser marking equipment, the laser output from the isolator head of the laser will mark the material at the focal position after being deflected by the galvanometer and focusing by the field lens. Therefore, the thermal lens effect is mainly produced on the galvanometer and field lens.

Galvo Fiber Laser Manufacturer China

1. The influence of the galvanometer thermal lens effect

The galvanometer is mainly composed of a drive board, a servo motor and an X-Y optical reflection lens. When the reflectivity of the reflective lens is low, there are impurities in the medium, and the surface is contaminated, the lens will be thermally deformed when irradiated by the laser beam, and the flat mirror will become a convex mirror. After the laser beam passes through the two reflective lenses, the output spot will change. Large, the focus spot becomes smaller and the focal depth becomes shorter after passing through the field lens.

2. The influence of field lens thermal lens effect

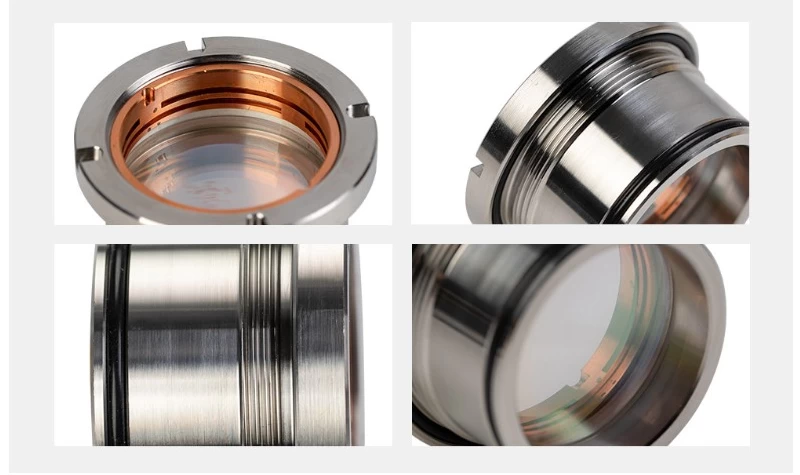

The field lens is used to focus the output spot in the fiber laser marking equipment, and its characteristic is that all the focal points are on a horizontal plane. The field lens is mainly composed of concave-convex lenses. When the transmittance of the lens group is low, there are impurities in the medium, and the surface is contaminated, the lens will be thermally deformed by the laser beam, and the focusing ability of the lens will become stronger, and the focused spot will become smaller and the focal length And the depth of focus becomes shorter. The focus is not on a horizontal plane, and the marking effect of the center and the edge is inconsistent.

China Optics Lens For Fiber Laser Wholesales

For example, when aluminum oxide is blacked, when the lens quality is not good, the focal length will be shortened, the energy is not enough, the marking is not black, the center and edge effects are inconsistent, and the focus needs to be readjusted.

The generation of the thermal lens effect will affect the stability of fiber laser marking, especially for the marking of sensitive materials. In order to reduce the thermal lens effect, the following measures can be taken:

1. Choose good quality galvanometer and field lens;

2. Daily maintenance of the galvanometer and field lens to prevent contamination of the lens by impurities;

3. Replace the damaged galvanometer and field lens;

4. Center the marking graphics and try to make the laser mark directly below the field lens;

CARMANHAAS is professional China Optics lens manufacturer to be leader supplier in china with best price. all our products are good with CE ISO quality certificated,enabling you to perform high-precision laser material processing Keep stable.