Which fields are suitable for hand-held laser welding? What should I pay attention to when using

Hand-held laser welding machine is one of the growth points of the rapid rise in the laser field in recent years. With many advantages such as high efficiency, flexible operation, high quality and low cost, it has been recognized by the market.

1. High efficiency: Speed is faster than the traditional welding speed by more than two times.

2. High quality: Smooth and beautiful welding seam, without subsequent grinding, saving time and cost.

3. Low cost: 80% to 90% power savings, processing costs are reduced by 30%

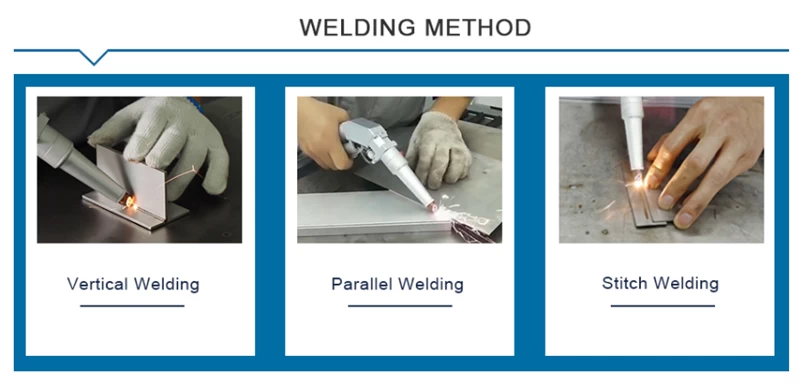

4. Flexible operation: Easy operation, no need experience can do a good job.

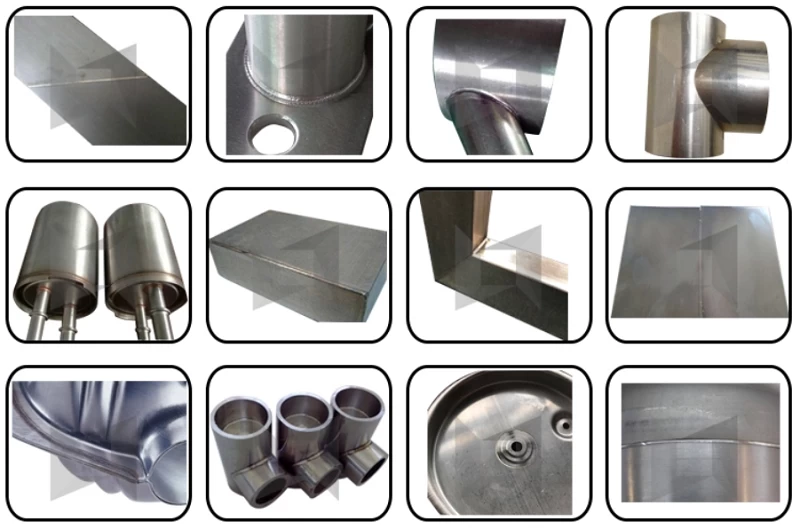

At present, the application fields of handheld laser welding are mainly concentrated in IT industry, medical equipment, communications equipment, aerospace, machinery manufacturing, battery manufacturing, elevator manufacturing, craft gifts, household appliances manufacturing, tooling, gears, automobile shipbuilding, watches and clocks, jewelry and other industries.(Handheld Welding Supplier China)

Handheld Fiber Laser Welding Machine suitable for welding of gold, silver, titanium, nickel, tin, copper, aluminum and other metal and its alloy material, can achieve the same precision welding between metal and dissimilar metals, has been widely used in aerospace equipment, shipbuilding, instrumentation, mechanical and electrical products, automotive and other industries.

Laser welding is fusing welding technology, laser welder puts laser beam as the energy source, and make it impact on the weld element joints to realize welding. It still has obvious advantages in terms of welding speed, welding quality, and subsequent processing (which can greatly reduce the labor cost of polishing and leveling procedures) in terms of welding speed, welding quality, and subsequent processing of metal materials such as thin stainless steel plates, iron plates, and aluminum plates, so there is a strong Potential to replace traditional craftsmanship. (Wholesales 1000W Handheld Fiber Laser Welding Machine)

Hand-held laser welding belongs to four types of laser products (greater than 500mW), which is harmful to the skin and eyes. Although the human eye cannot directly see the laser in the infrared band, the welding head of hand-held welding has a certain angle with the surface of the workpiece. Part of the laser light is reflected, especially when welding high-reflective materials such as copper and aluminum, the reflected laser energy is greater. If it is reflected into the eyes, it will cause irreversible damage to the retina. Therefore, we hereby call upon users who hand-held laser welding to wear laser goggles!