Application of laser cutting in medical equipment industry

After the epidemic, many medical device manufacturers used their horsepower to produce and process protective equipment, and medical devices became popular for a while. However, due to insufficient preparation and shortage of production equipment in some regions, the protection materials were strained. The adjustment of our protective materials basically meets the needs of the public. This aspect is attributed to the overtime and overtime production of existing equipment manufacturers. On the other hand, due to the large-scale production equipment supply, the demand for expanding production has been solved to a certain extent. When it comes to equipment manufacturing, you have to mention the application of laser cutting machines in the medical device industry.

Medical equipment is concerned with the safety of human life and plays an important role in human life. The high-precision fiber laser cutting machine escorts the safety of human life. The fiber laser cutting machine can process very small wedge angles and high aspect ratio cutting parts. Compared with traditional laser processing, both the slit width, the slit angle, and the thickness of the recast layer are significantly reduced.

Due to the special use environment of medical devices, its precision, safety, smoothness, sanitary conditions and processing and processing equipment have higher requirements. The traditional sheet metal mechanical cutting processing mode exists in terms of accuracy and safety controllability There are great defects, and laser cutting meets the requirements of medical professions in terms of precision, safety, and smoothness. Fiber laser cutting is to scan the surface of the material with a high-power density laser beam, heat the material to thousands to tens of thousands of degrees Celsius in a very short time, melt or vaporize the material, and then use high-pressure gas to cut the molten or vaporized substance from the material. Blow away in the slit to achieve the purpose of cutting material. This extremely high temperature cutting guarantees the possibility of not being secondarily contaminated during the processing of the instrument; there is also a very good surface finish of the processed material, which can meet the requirements of one-time molding and avoid two or more times after the material is formed Reprocessing causes time and material loss.

In terms of the workpiece itself, medical devices are very different from other mechanical parts. It requires very high precision without any deviations, and the laser cutting machine can meet these processing requirements well when processing and cutting instruments.

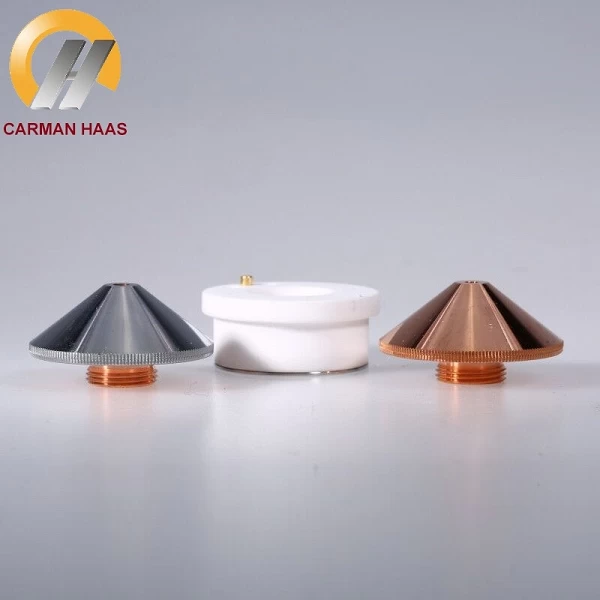

Fiber laser cutting nozzle manufacturer china

In addition, the slit produced by laser cutting is very narrow, and the laser beam is focused into a very small light spot, so that the focal point reaches a high power density, and the material is quickly heated to the degree of vaporization and evaporated to form a hole. As the beam and the material move relatively linearly, the hole continuously forms a slit with a very narrow width, and the slit width is generally 0.10-0.20 mm. The extremely small cutting seam ensures high cutting precision.

The production process of the laser cutting machine is a non-contact process. The laser cutting head will not contact the surface of the processed material and will not scratch the workpiece. For medical devices, surface finish is the most basic requirement. If the surface grinding process of device products can be minimized during processing, the production efficiency will be greatly improved.

my country's medical device processing and manufacturing technology is severely restricted by the level of sheet metal processing. Until the application of high-precision processing equipment for laser cutting machines, the manufacturing quality of my country's medical equipment has been greatly improved, the sales of medical equipment have increased, and the development of the medical industry has also accelerated.