Application of laser technology in power battery manufacturing

What is a power battery?

The batteries that provide driving power for electric vehicles are called power batteries, including traditional lead-acid batteries, nickel-metal hydride batteries, and emerging lithium-ion power batteries. They are divided into power-type power batteries (hybrid vehicles) and energy-type power batteries (pure batteries). Electric vehicles), the endurance of electric vehicles is closely related to the battery.

Power battery manufacturer china

The production of power batteries consists of three parts: pole piece production (front end), core assembly (middle section) and post-processing (rear section). Laser technology is widely used in the production of front pole pieces, middle welding and rear module packaging of power batteries.

Laser cutting is a process that uses high-power density laser beams to achieve cutting. Mainly used for laser lug cutting and forming, pole piece cutting, laser pole piece segmentation, diaphragm laser cutting, etc.

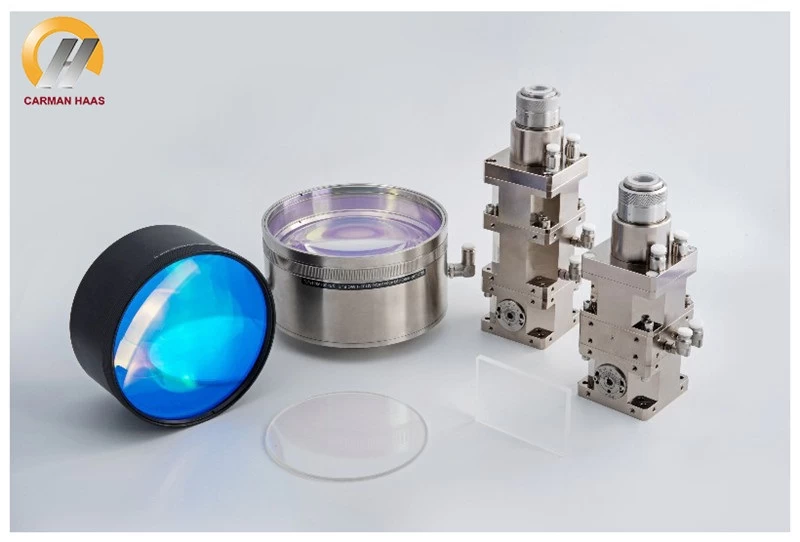

Power battery laser cutting lens

Before the advent of laser technology, the power battery industry generally used traditional machinery for cutting processing, but the cutting machine was worn out during use, dust and burrs fell, causing the battery to overheat, short circuit, and explosion. Traditional cutting technology has rapid mold loss and switching time. Long, poor flexibility, low production efficiency and other issues. In the processing of power battery tabs, laser cutting has become a standard in the industry.

Laser welding uses the excellent directivity and high power density of the laser beam to work. The laser beam is focused in a small area through the optical system, and the welded area forms a highly concentrated heat source in a very short time Zone, so that the welded object melts and forms a firm solder joint and weld. As a high-precision welding method, it is extremely flexible, precise and efficient, and can meet the performance requirements in the power battery production process. It is the first choice in the power battery manufacturing process. It has become the standard equipment of the power battery production line.

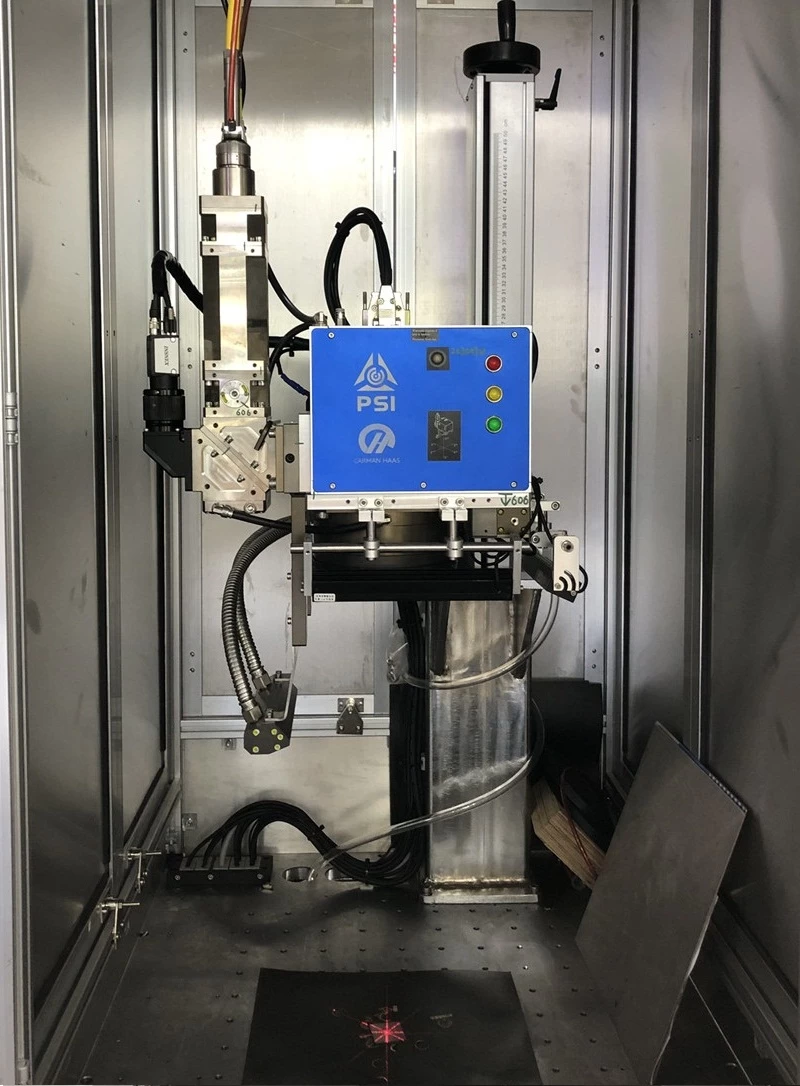

Galvo head laser welding manufacturer china

The innovation of laser processing technology plays a prominent role in the production of power batteries. Compared with traditional mechanical cutting, it has the advantages of no wear of cutting tools, flexible cutting shape, controllable edge quality, high precision, and low operating cost. It helps reduce manufacturing costs, improve production efficiency and shorten the die-cutting cycle of new products.