Cleaning of dust, stains and impurities on the surface of optical components

Dust and stains on the surface of optical components can cause light scattering, while impurities on the surface can interact with the laser to damage the optical coating. Using the correct cleaning and maintenance methods can effectively avoid damage to optical components and extend the service life.

General tips

If it is not dirty, do not clean it! Handling optical components increases the chance of contamination and damage. Therefore, the optical elements are not cleaned unless necessary.

When cleaning optical components, they should be carried out in a clean and dust-free environment, and wear powder-free anti-acetone gloves or finger cots. Grease or shed debris secreted by the skin can contaminate and damage the membrane, so do not directly touch the optical surface with your hands or reuse lens paper. Be aware that lens paper is much cheaper than optical components.

Place the optical element to be cleaned under a bright visible light source and inspect its surface from different angles so that you can see the light scattered from the attached dust and stains.

Co2 Laser Head With Mirror Mount

1. Use an air cleaner

Removal of particulate dust is usually the first step in cleaning optical components. Wiping the surface of the optical element is equivalent to sanding it with sandpaper! Therefore, before wiping any optical element, try to blow the surface of the optical element with compressed filtered air or nitrogen. If the dust on the surface is removed, remember "If it is not dirty, do not clean it". If it is still not clean, choosing the right solvent and lens paper can usually achieve a good cleaning effect.

2. Use solvent and lens paper

The method of use depends on the specific optical components, but be sure to move gently and clean the edges first.

Cleaning solutions usually leave marks on the surface of optical components, and paper towels can easily cause scratches. Therefore, it is necessary to use reagent grade and spectrally pure grade solvents and anti-desmear lens paper for optical cleaning. The lens paper should be used with solvents, because the dry lens paper will scratch the surface of the optical element.

A better solvent is a mixed solution of 60% acetone and 40% methanol. Pure acetone is too volatile to effectively remove all impurities, while methanol can slow down the evaporation and can help dissolve impurities that acetone cannot dissolve. Isopropyl alcohol is safe and effective, but it evaporates slowly, and it is easy to leave marks on the surface of optical components. When cleaning, first clean the edge of the optical element to avoid bringing contamination to the central part. Wipe slowly to fully evaporate the solvent without leaving traces.

Note: Please wear anti-acetone gloves when using acetone.

China Professional Znse Round Protection Window Manufacturer

"Drag" technology

The "drag" technology is ideal for cleaning optical components that have not yet been fixed, such as our 51xx lenses and 580x beam samples.

Place the optical components on a clean, non-friction surface, such as a clean cloth for cleaning. First blow the surface of the component with clean compressed air or nitrogen, then cover the surface with a layer of lens paper, add a little solvent on top, and then slowly drag the invading lens paper across the surface of the component.

Infiltrate the lens paper with solvent, cover the lens paper with the optical element, and slowly drag it across the surface of the element. Remember to clean the edges before cleaning the surface.

"Wipe" technology

For smaller optical components, such as our 515x lenses and 581x cube beamsplitters, you can use the "wiping" technique to clean, from one side of the surface to the other in one direction.

Fold the lens paper to the width of the optical element to be cleaned. Do not touch the lens paper that touches the surface of the component with your hands. Use hemostatic forceps or tweezers to hold the folded lens paper parallel to the crease, close to the crease, wet the lens paper with acetone and shake off the excess acetone.

First try to blow away the dust on the surface. Use hemostatic forceps or tweezers to hold the lens paper, apply a little force, gently wipe from one side of the component surface, and wipe in one direction to the other side.

Note: When cleaning the 581x cube beam splitter, avoid solvent penetration into the gap between the two prisms of the beam splitter, so as not to damage the adhesive in the middle.

For those hard-to-reach areas, you can use lens paper wrapped on the soft end of a cotton swab to wipe. At the center of the optical surface, wipe continuously around the circumference in the same direction to avoid leaving marks.

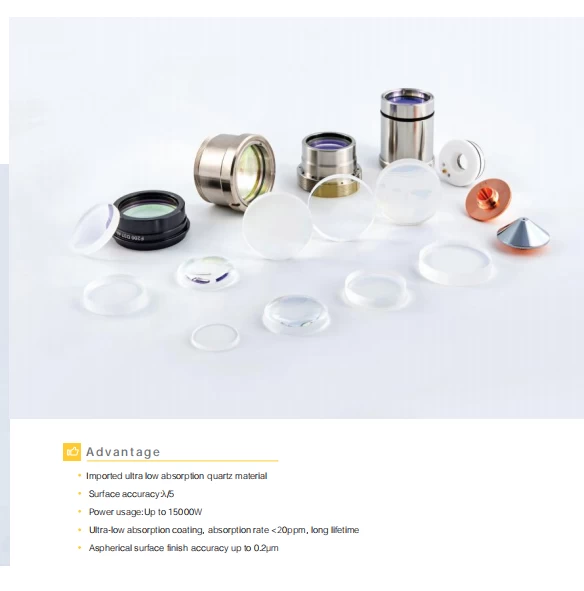

Aspheric Fused Silica Focusing lens

"Erase" technology (not recommended for metal coated optical components)

"Erase" technology is suitable for cleaning stubborn stains on relatively durable optical coatings. Fold the lens paper as described in the "wiping" technique above, hold the lens paper with your hands instead of tweezers, and apply even force to wipe the surface of the optical element in the same direction.

"Immersion" technology

For relatively fragile coatings, which are vulnerable to damage, we recommend using the so-called "soak" technique for cleaning. First try to blow off the dust on the surface, and then soak the optical components in acetone. If the component is dirty, you can choose to put it in the ultrasonic cleaner. Rinse and immerse in clean solvent multiple times until the optics are cleaned. When drying, carefully blow the solvent on the surface in one direction to avoid leaving marks.

Storage after cleaning

Fix the optical element to the bracket or platform to be used, or wrap it with lens paper and store it in a suitable container and packaging box.