Disassembly method of optical fiber and laser head

1. Cut off water and electricity

Turn off the water chiller and stop the water flow. Turn off the laser key switch, and then turn off the laser main switch to stop the laser. Turn off the machine tool to stop the laser head from working.

Remove the cooling water pipe of the fiber connector

Prepare the water container, absorbent paper or cloth, and short-circuit the cooling water pipe before removing the quick plug. Make sure that the water cooler has been shut down and the water flow in the water pipe has stopped, because when the water pipe is unplugged, there is residual water pressure in the water pipe and it will overflow slightly. A small amount of water, catch the water with a water receiving box, and wipe it clean with absorbent paper or cloth. Short-circuit the cooling water pipe with a quick plug or directly tie it with a cable tie to prevent water from flowing out of the pipe.

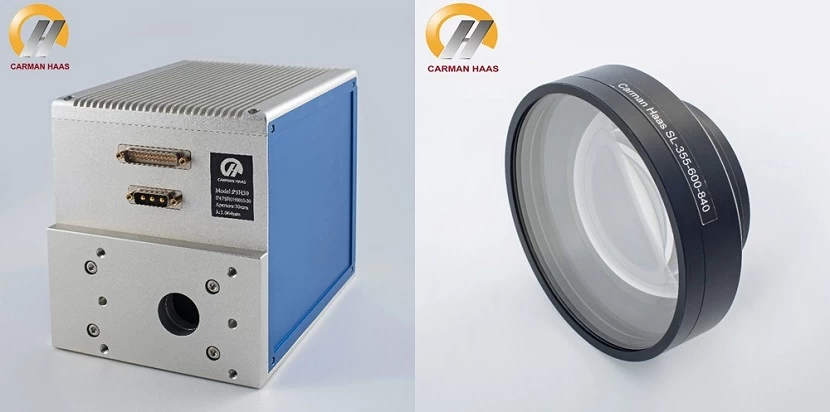

Customized galvo laser head manufacturer

2. Unplug the fiber

Operators wear rubber gloves to wash their hands and keep their hands clean and dust-free. Prepare the protective cover of the laser head, optical fiber cap, clean compressed gas, dust-free wipes, isopropyl alcohol, turn off the air conditioner or fan to reduce air flow. Dust-free wipes are sprayed with isopropyl alcohol, and the outer surfaces of the laser head, optical fiber connectors, and cable water pipes near the optical fiber connectors are wiped clean with a dust-free cloth to ensure that the area near the optical fiber connectors does not raise dust.

Put the laser head connected to the optical fiber into a dust-free box or a clean desktop, clean the laser head protective cover and the optical fiber cap with a dust-free cloth, and then use clean compressed gas to blow off the dust on the protective cover and optical fiber cap, and adjust the position of the laser head. Place the laser head horizontally with the laser head socket facing horizontally, so that dust can be prevented from falling into the laser head and contaminating the lens when inserting and removing the optical fiber.

Unplug the fiber connector. First, seal the laser head with a clean protective cover as soon as possible. Then, seal the fiber connector with a fiber cap as soon as possible.

Co2 Laser Head With Mirror Mount wholesales

3. Handling fiber optic connectors

Prepare the golden finger tape to dust-proof the fiber protective cover and the fiber interface, which is convenient for next use.

Return the fiber from the laser head position to the laser position carefully to avoid twisting, falling, or stepping on it. The minimum bending radius of the fiber without stress is 0.1m. Excessive bending will damage the fiber. We stipulate the minimum allowable bending limit when coiling the fiber. This rule is not defined by the bending radius, but calculated as the length of a coil of 1.5m. Avoid breathing and talking towards the opened laser head socket to prevent saliva from flying. Foam enters the optical head.