How to avoid secondary pollution of laser galvanometer

All lenses mostly absorb a specific laser wavelength due to manufacturing process or external pollution, which will shorten the life of the lens over time. The damage of the lens will affect the use or even stoppage.

1. The thermal lens effect caused by the high absorption of the lens due to pollution will cause many problems. The generation of irreversible thermal stress on the lens substrate, the power loss generated when the beam propagates through the lens, the deflection of the focused spot position, and the premature damage of the coating layer can all cause damage to the lens.

2. For the lenses exposed to the air, when cleaning, the requirements and precautions for lens cleaning are often not followed, and the materials are taken casually. The result will cause new pollution or even scratch the lens, causing irreparable losses.

No matter which type of optical lens is kept clean, it is most important to have good cleaning habits to carefully clean the lens, which can reduce or eliminate the pollution caused by man-made reasons.

1. When operating the optical system by hand, wear finger cots or medical gloves regardless of cleaning, disassembly, and installation. During the cleaning process, only use the specified materials, such as optical lens tissue, cotton swabs, and reagents. Grade ethanol.

2. Any lens cleaning, disassembly, and installation shortcuts will shorten the life of the lens or even permanently damage it. Therefore, it is necessary to use common sense to prevent the lens from being contaminated by other reasons, such as protection from moisture, smoke, dust, etc.

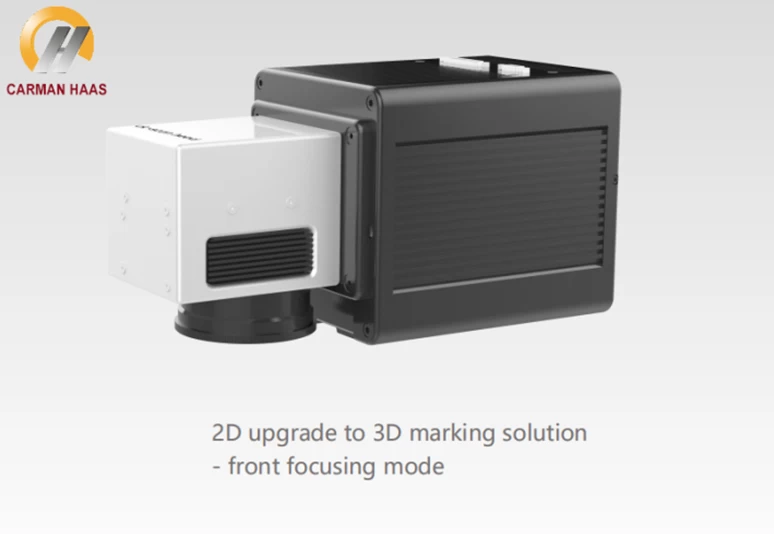

customized galvo laser head manufacturer

3. After confirming that a certain lens is contaminated, blow the lens with an ear-washing ball until there are no particles on the surface. Never blow with your mouth. Because most of the air blown out contains oil, water, etc., it will further contaminate the lens. If there is still contamination on the surface after the ear wash ball is processed, you must use a special cotton swab dipped in laboratory grade acetone and ethanol to gently wipe it.

If we can keep the lenses clean, it will extend the life of the whole machine.