Metal 3D additive manufacturing process-powder bed fusion technology

What exactly is 3D printing technology?

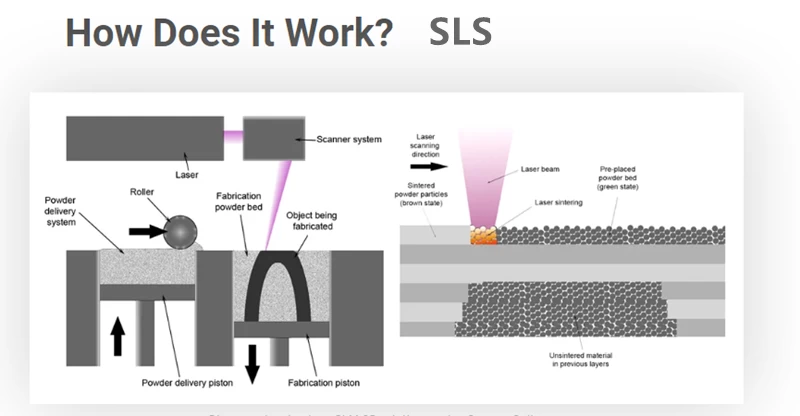

Additive manufacturing: A manufacturing process that involves manipulating a very small amount of material at a time so that continuous materials are combined in the correct form to generate the required parts directly from the CAD model. A very simple process, which requires "two-dimensional" operations on the most complex parts, and the products are processed layer by layer.

3D Printing Metal on Sale Supplier,printing process: powder bed fusion technology

Metal powder bed fusion is a 3D printing process that produces solids and uses a heat source to fuse metal powder particles in one layer at a time. Most powder bed fusion technologies use the mechanism of adding powder when constructing the object, so that the final component is encapsulated in metal powder. The main change in metal powder bed fusion technology comes from the use of different energy sources. Two types of technologies are classified into laser or electron beam.

Technical features:

Types of 3D printing technology: Direct Metal Laser Sintering (DMLS); Selective Laser Melting (SLM); Electron Beam Melting (EBM)

Material: Metal powder: aluminum, stainless steel, titanium

Dimensional accuracy: ±0.1mm

Common applications: functional metal parts (aerospace and automotive); medical; dental

Advantages: the most robust functional components; complex geometry

Disadvantages: small size; the highest price of all technologies

Direct metal laser sintering (DMLS) and selective laser melting (SLM) are both compatible with SLS (Selective Laser Sintering (SLS)) similarly generates objects. The main difference is that these types of 3D printing technologies are suitable for the production of metal parts. DMLS does not melt the powder, but heats it to a certain degree so that it can fuse together at the molecular level. SLM uses a laser to completely melt the metal powder to form a uniform part.

Electron beam melting (EBM), unlike other powder bed melting technologies, electron beam melting (EBM) uses high-energy beams or electrons to initiate melting between metal powder particles. The focused electron beam sweeps through the thin layer of powder, causing local melting and solidification in a specific cross-sectional area. Establish these areas to create entities. The important point is that EBM parts are manufactured in vacuum, and this process can only be used with conductive materials.