Precautions for installing QBH optical lens on fiber end face

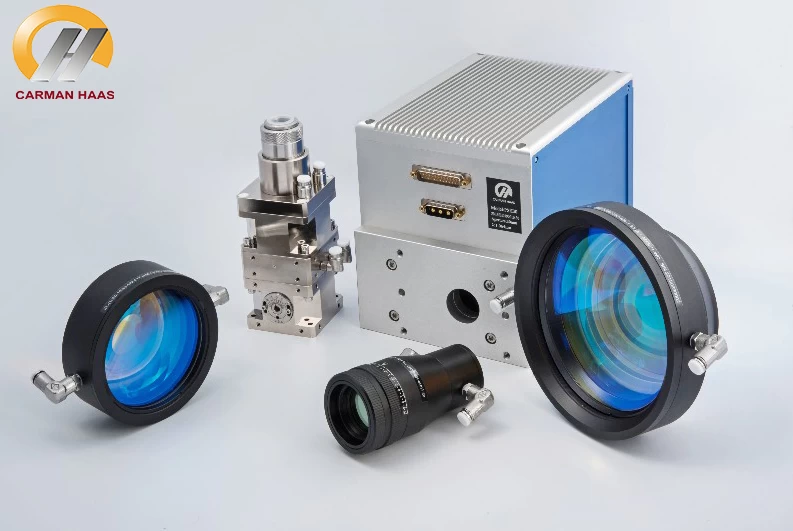

Due to the excellent flexibility of the fiber, the laser can be designed to be quite small and flexible, compact and small in size, easy to system integration, and cost-effective. Fiber lasers are increasingly widely used in industrial fields such as laser cutting, laser welding, and laser cladding.(QBH Optical Modul Supplier China)

As a waveguide medium, optical fiber has high coupling efficiency, small core diameter, high power density within the fiber, and high throughput per unit area. If the laser is not cleaned properly in the application, it will easily cause the laser output head to burn out and affect the laser power output And the stability of the laser. At the same time, the maintenance cycle is long and the maintenance cost is high, causing serious economic losses.

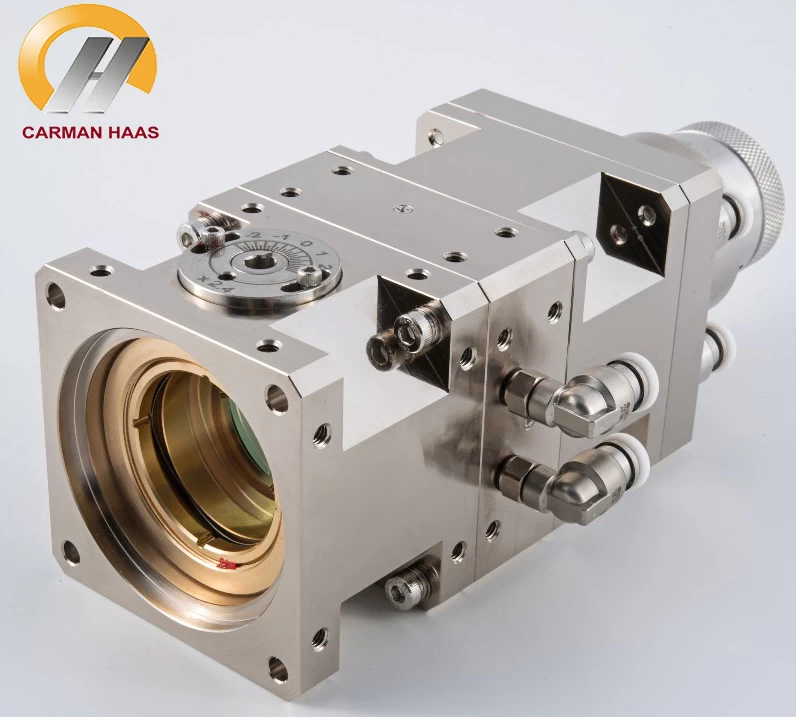

In order to ensure the long-term stable operation of the laser and better ensure the stability of the QBH output head,(China QBH Optical Modul Manufacturer) each time the fiber end is connected to the optical head, it is necessary to check whether there is dust or dirt on the fiber end face, and clean it if necessary. At the same time, if the fiber end face has dust or is not clean, it will contaminate the quartz column and cause serious damage to the laser.

Necessary materials and tools

When cleaning the fiber end face, you need to prepare the following materials and tools: Kodak lens paper, optical cleaning stick, acetone (no water and oil) or absolute ethanol (≥99.7%), microscope, flashlight, optical QBH optical lens that has been confirmed to be clean and intact .

Precautions

(1) The cleaned fiber end should be quickly installed into the QBH optical lens. Long-term exposure to the air will cause secondary pollution. When inserting the optical lens, keep the output head and the optical lens inserted horizontally, and it is forbidden to insert the optical head vertically.

When connecting with the QHB connector, pay attention to open the lock lock as to the open state, and align the red spot on the fiber head with the red spot on the QHB connector before inserting. After inserting the optical fiber head, press the QBH state lock to lock it.

(2) Be patient and meticulous when operating. It also requires a clean surrounding environment, workplace and auxiliary equipment. Only use special lens paper for cleaning. The use of general lens paper is prohibited.

(3) Excessive cleaning, wrong cleaning and lead contamination may damage the optical fiber output head.