Single-axis and dual-axis galvanometer

Galvo scanner is abbreviated as Galvo, A mechanical scanner contains a physical mirror driven by a certain motor. Most of the time, the mirror is connected to the shaft of the motor, but in some designs, the mirror and motor may be a single integrated unit.

The main advantages of galvanometer laser scanning are high speed and high precision, which are widely used in laser processing, life sciences and medical diagnosis. The galvanometer can be used in a single axis or in a multi-axis configuration, or can be combined with complementary technologies (such as resonance or polygon scanner) to achieve more complex scanning shapes.

Single-axis and dual-axis galvanometer

The single-axis galvanometer kit generally includes a galvanometer mirror, a servo amplifier and a connecting cable. Mirror coating options include broadband films for infrared and visible light and dielectric films for specific single or multiple wavelengths. A complete galvanometer application also requires the purchase of various accessories, servo radiators, galvanometer mounting fixtures, signal sources and light sources, and so on.

galvo fiber laser manufacturer china

The dual-axis galvanometer is the core building block for OEM processing and three-axis systems. The matched and tuned XY dual-axis galvanometer is the key to building a high-performance scanning system. The two mirrors must ensure precise optical path alignment.

In addition, the dual-axis galvanometer scanning head is compatible with a variety of lasers, and the optional lens provides the best spot, working distance and field of view to increase the laser processing speed.

How to choose the right scanning head?

We suggest starting from the laser processing requirements, the processing efficiency depends on how efficiently the beam energy is transferred to the surface of the workpiece. The dual-axis scanning head adopts the scanning configuration in front of the objective lens, that is, the moving mirror is located in front of the objective lens. The lens must have a flat field of view to evenly focus the light spot on the entire work surface.

The fθ lens is the most commonly used scanning lens. Its scanning field is larger than the lens, the light spot is circular in the center of the field of view, and the four corners are a bit elliptical, so it is slightly uneven. Long-wavelength applications such as CO2 lasers can often only use a single lens. Short-wavelength applications such as UV 255 nm to 1064 nm YAG lasers require multi-element lenses to provide high-quality light spots.

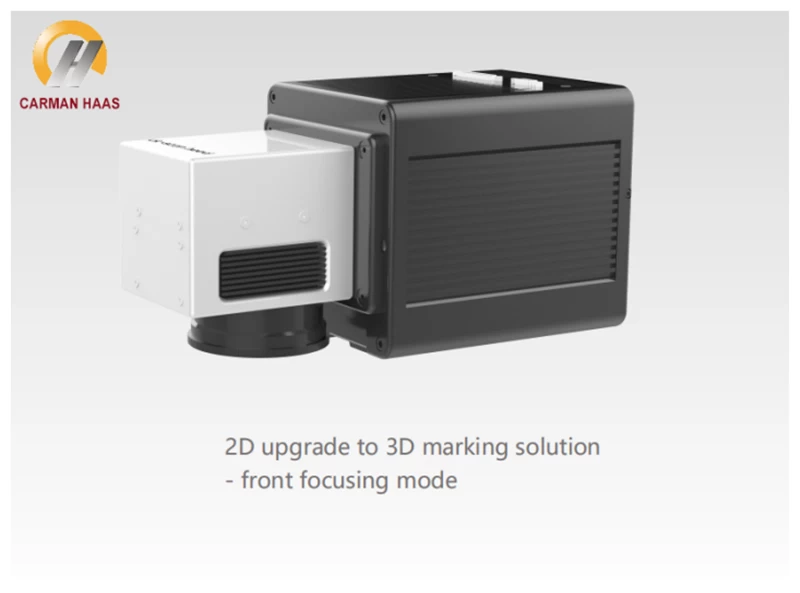

3D Galvo scanner head for engraving

Although telecentric lenses are not commonly used here, they are also introduced for completeness. The scanning field of the telecentric lens is equal to or smaller than the diameter of the lens, the laser is always incident on the working surface, and the spot size and energy density remain consistent throughout the field of view.

The dual-axis scan head and fθ lens are suitable for flat objects and a field of view of about 6 inches, but the solar panel may be much larger than this, so a three-axis scan head with a larger field of view is needed.