The development trend of laser cleaning

Traditional cleaning industrial equipment has a variety of cleaning methods, mostly using chemical agents and mechanical methods for cleaning. In today's increasingly strict environmental protection laws and regulations, and people's increasing awareness of environmental protection and safety, the types of chemicals that can be used in industrial production cleaning will become fewer and fewer. How to find a cleaner and non-invasive cleaning method is a problem we have to consider.

The laser cleaning has the characteristics of no grinding, non-contact, low heat effect and suitable for objects of various materials, and is considered to be the most reliable and effective solution.

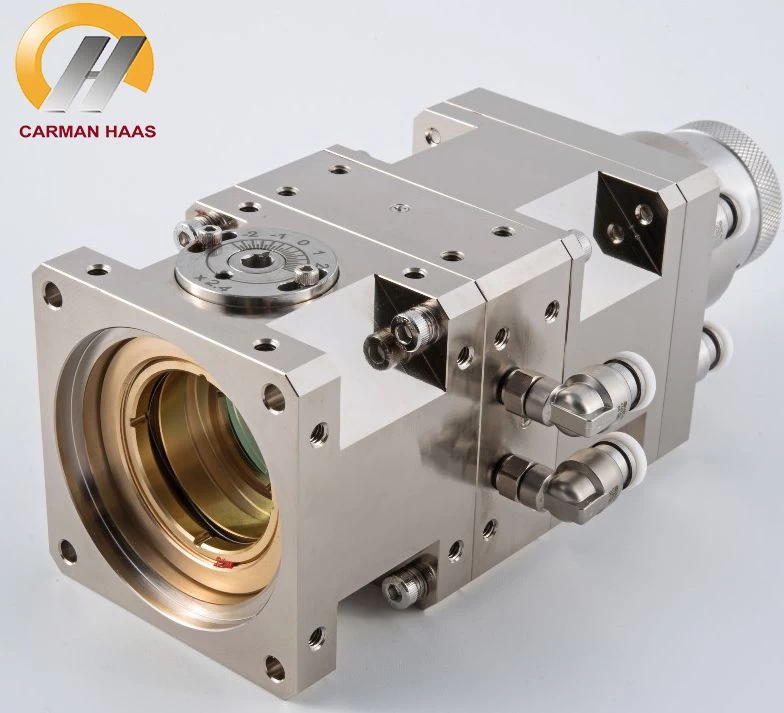

Optical Module for Laser Welding, Additive manufacturing(3D Printing ) and Laser Cleaning system

advantage

Compared with traditional cleaning methods such as mechanical friction cleaning, chemical corrosion cleaning, liquid solid strong impact cleaning, and high-frequency ultrasonic cleaning, laser cleaning has obvious advantages.

1. Laser cleaning is a "green" cleaning method, without the use of any chemical agents and cleaning fluids, the wastes cleaned are basically solid powder, small size, easy to store, recyclable, and can easily solve the chemical cleaning belt Coming environmental pollution issues;

2. The traditional cleaning method is often contact cleaning, which has a mechanical force on the surface of the cleaning object, the surface of the damaged object or the cleaning medium is attached to the surface of the object to be cleaned, and cannot be removed, resulting in secondary pollution, no grinding of laser cleaning Harmony and non-contact make these problems solved easily;

3. The laser can be transmitted through the optical fiber, cooperate with the robot hand and the robot, conveniently realize long-distance operation, and can clean the parts that are difficult to reach by traditional methods, which can ensure the safety of personnel when used in some dangerous places;

4. Laser cleaning can remove various types of contaminants on the surface of various materials to achieve a degree of cleanliness that conventional cleaning cannot. And it can also selectively clean contaminants on the surface of the material without damaging the surface of the material;

5. Laser cleaning efficiency is high, saving time;

Current domestic development status of laser cleaning technology

Laser cleaning technology is a new type of cleaning technology developed rapidly in the past 10 years. It has gradually replaced the traditional cleaning process in many fields with its own advantages and irreplaceability.

At present, the development of laser cleaning technology is uneven, and it has been partially industrialized in high-end manufacturing fields, such as semiconductors, marine equipment, automobile manufacturing, aerospace, and high-speed rail transportation. Nowadays, advanced manufacturing has become the commanding height of international competition. The development of laser cleaning technology has very important strategic significance for the substantial improvement of my country's equipment international competitiveness, economic and social development.

Although laser cleaning can not completely replace the traditional cleaning technology at present, with the advancement of technology and the improvement of environmental protection requirements, laser cleaning will become a major trend in the development of the global cleaning market. By developing new laser cleaning systems and equipment and optimizing the cleaning process, the cleaning efficiency is improved, the cleaning cost is reduced, the damage to the surface to be cleaned is reduced, and the green, efficient and automated cleaning process of metal surfaces is bound to be the future market demand.