The difference between laser static scanning and dynamic scanning in 3D printing

The front focus galvanometer is called a dynamic focus galvanometer (pre-scan), and the rear focus galvanometer is the most common galvanometer (post-scan) we usually use. Generally, the ordinary marking machine uses the rear focus galvanometer scheme.

pre-scan:

Front focusing system(Post objective scanning system manufacturer)

In large-format laser marking machines or 3D printers that use dynamic focus, a long focal length dynamic focus device is used before the galvanometer is scanned. The light spot output by the laser is focused by the dynamic focus lens, and the focused focal length is greater than the distance between the dynamic focus lens and the galvanometer. That is, scanning is performed during the focusing of the beam. Since the distance between the workpiece plane and the focusing lens is constantly changing during the planar scanning process, it is impossible to mark the workpiece plane if the focal length of the focusing lens is fixed. This is why dynamic focus is used. According to the distance between each point of the workpiece plane and the focusing lens, the focal length of the focusing lens is changed, so that all the focused light spots are concentrated in the plane where the workpiece is located. The galvanometer scanning method with dynamic focus can extend the focal length, thereby increasing the scanning area. It is currently the best solution for large-format high-speed scanning. This method is a typical galvanometer type pre-scan.

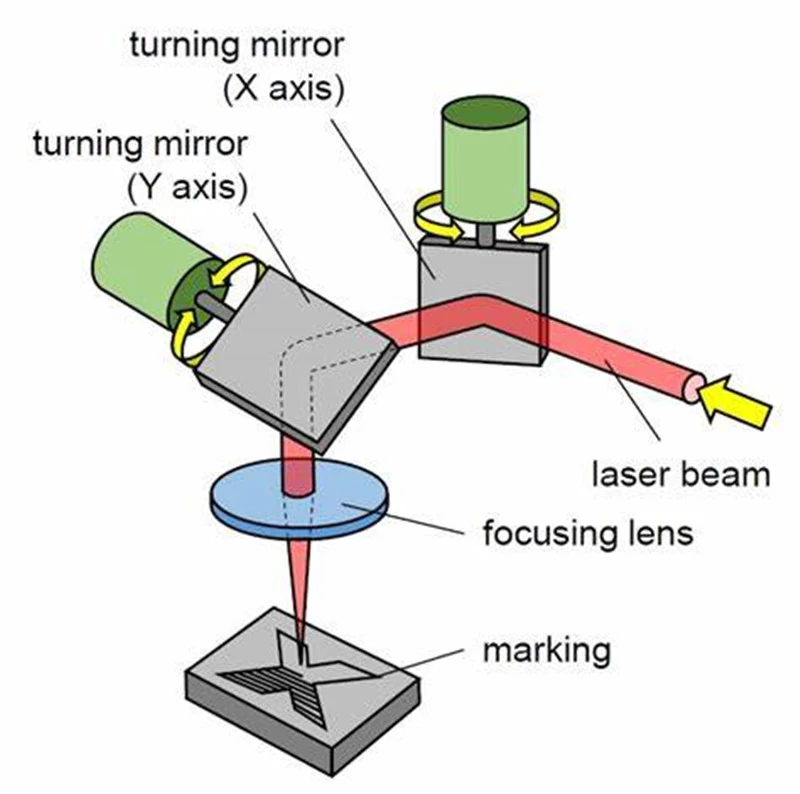

post-scan:

Rear focus system(gavlo scanner wholesales china)

Ordinary galvanometer-type equipment (marking machines, 3D printers) uses the laser beam output to scan through the galvanometer first, and then focus on the scanning plane through the lens, this method is relatively easy to control, but can be scanned by the lens The size of the focused spot in the scanning plane is different, the center is smaller, and the edge is larger, which is prone to pincushion and drum distortion. At present, the distance of the lens is generally adjusted to reduce the distortion of the surrounding light spot and improve the accuracy. This method is simple and easy to implement in algorithm. It can be implemented on some smaller working areas and the accuracy is easy to control. Because the advantage of this method is that the control software is easy to implement, the cost is lower, and the speed is faster, and it is adopted by most galvanometer scanning equipment manufacturers.