Three methods of laser cutting machine to determine focus

In the CO2 laser cutting machine, several key technologies must be mastered and solved for parts with higher cutting accuracy or larger thickness. Focus position control technology is one of them.

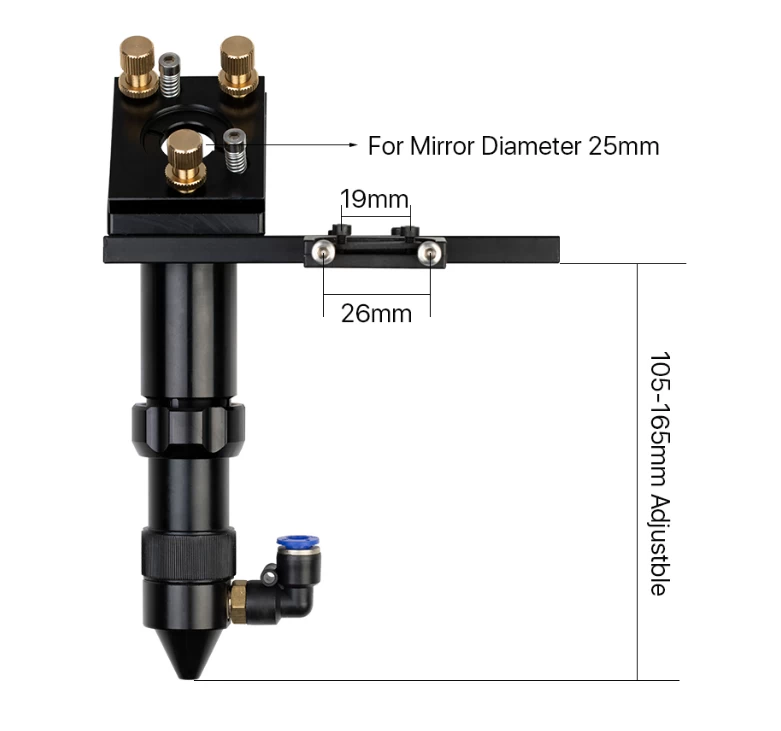

CO2 Laser Engraving Cutting Machine wholesales

One of the advantages of laser cutting is that the energy density of the beam is high, so the focal spot diameter is as small as possible in order to produce a narrow slit. Because the smaller the focal depth of the focusing lens, the smaller the focal spot diameter. For high-quality cutting, the effective focal depth is also related to the lens diameter and the material being cut. Therefore, it is very important to control the position of the focus relative to the surface of the material being cut.

CO2 Cutting Machine Parts manufacturer china

There are three easy ways to determine the focal position in industrial production:

(1) Printing method: The cutting head is moved from top to bottom, and laser beam printing is performed on the plastic plate, with the smallest printing diameter as the focus.

(2) Inclined plate method: Use a plastic plate placed obliquely at an angle to the vertical axis to pull it horizontally to find the smallest point of the laser beam as the focus.(Co2 laser mirror wholesales)

(3) Blue spark method: remove the nozzle, blow air, hit the pulse laser on the stainless steel plate, and make the cutting head move from top to bottom until the largest blue spark is the focus.