What are the advantages of laser etching?

The basic principle of laser etching is to focus a low-power laser with high beam quality (usually ultraviolet laser, fiber laser) on a very small spot, and form a high power density at the focus, so that the material evaporates instantly, forming holes, grooves, etc. extremely small power density. Realize laser micro-nano cutting, etching, drilling and other processes.

Best Price Laser Etching China

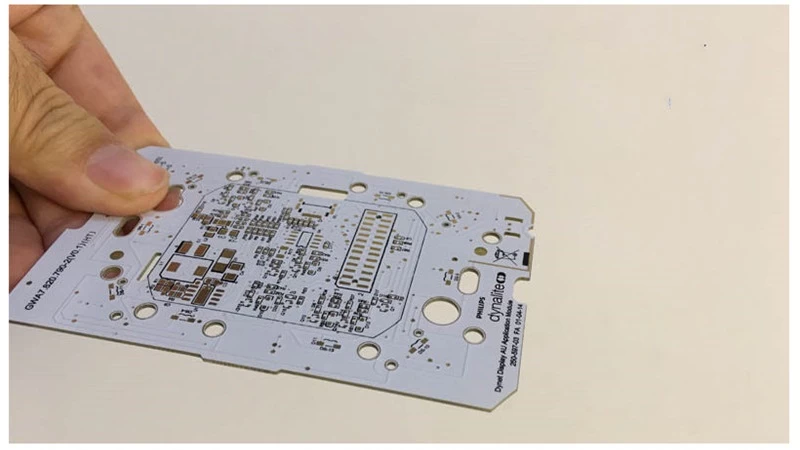

Laser etching mainly used in metal etching, etching signs, etching hardware and PCB circuit boards. So what are the advantages of etching processing?

1. The etched products have no burrs and high production efficiency. Large batches and dense small holes can also be stably produced in batches.

2. The precision can be higher and higher, and the highest control precision can reach +/-0.005mm.

3. Etching processing is especially suitable for the processing of precision thin materials such as stainless steel, copper and other materials, and there is no deformation during processing, and the tolerance requirements are strict.

4. The processed products have no burrs, no dirt, and the surface is smoother. Etching processing is a high-precision product that cannot be processed by other mechanical processes.

Carmanhaas offer professional laser etching system and optical components used in circuit board etching. These optical systems are generally composed of galvanometer scanning systems, including beam expanders, galvanometers and F-THETA scan lens.(China ITO-cutting lens price Wholesale)