What are the advantages of laser welding machine in the field of thin plate welding?

Analysis of the advantages of laser welding machine in the field of thin plate welding:

Stainless steel materials are widely used in the manufacture of various finished products, and the welding of stainless steel sheets has become an important process in the production process. However, due to the characteristics of thin-plate stainless steel, it also caused certain difficulties in welding, and it once became a welding problem in the field of thin-plate stainless steel.

Wholesales 1000W Handheld Fiber Laser Welding Machine

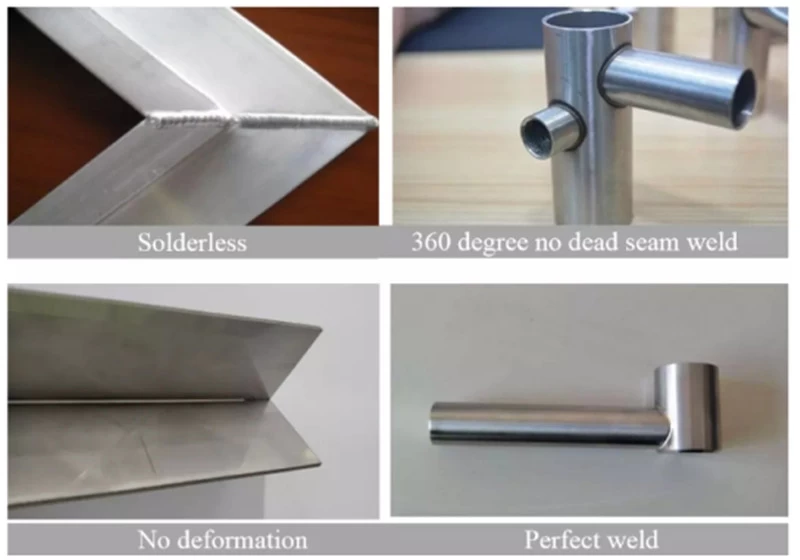

The traditional welding machine has a big problem in processing thin-plate stainless steel. Because of its small thermal conductivity, thin-plate stainless steel is only about one-third of ordinary low-carbon steel, and the degree of restriction is small. Therefore, once it is locally heated and cooled during the welding process The effect of the welding line will cause uneven stress and strain. The longitudinal shrinkage of the weld will produce a certain pressure on the outer edge of the stainless steel sheet. Once the pressure of the traditional welding machine is too large, it will cause the wave-like deformation of the workpiece, which not only affects the appearance, but also affects In addition to the quality of the workpiece, there will also be problems of overburning and burning through.

The emergence of fiber laser welding machine has solved this problem well.(Laser Welding Machine 800W/1000W Supplier) Laser welding a high efficient precision welding method which is in the use of high energy density laser beam as a heat source. Laser welding is one of the important aspects of laser processing technology. Laser radiates and heats the work piece surface, The surface heat diffuses to the inside through heat conduction, Then the laser makes the work piece melting and form the specific welding pool by controlling the laser pulse width, energy, peak power and repetition frequency. Due to its unique advantages, it has been successfully applied to the precise welding for micro parts and small parts. The weld seam is thin, the penetration depth is large, the taper is small, the appearance is smooth, flat and beautiful.no treatment or simple treatment after welding, high welding seam quality, no porosity, and precise control , The focused light spot is small, the positioning accuracy is high, and it is easy to realize automation. With many advantages, laser welding machines are gradually replacing the traditional thin plate welding market.

Laser welding machines are widely used in dental denture processing, circuit board welding, splicing steel plate welding, sensor welding, and battery sealing cover welding.

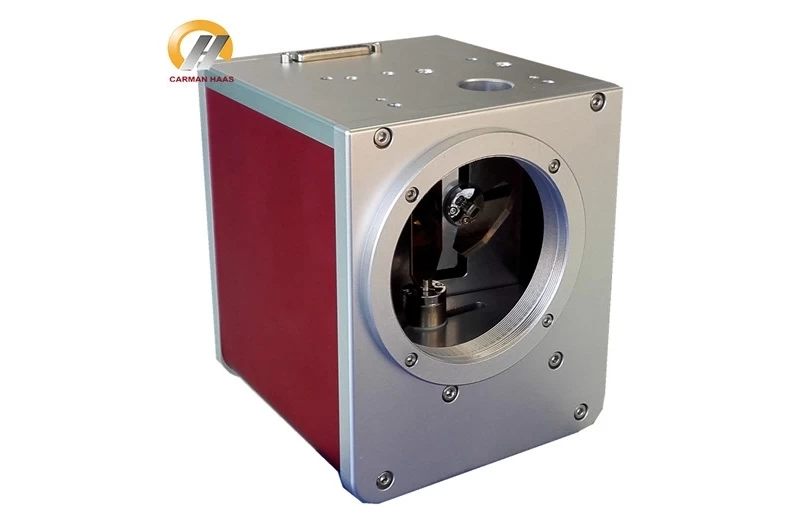

CARMANHAAS laser optical component manufacturer、Laser Welding Factory China can provide you with more laser welding component products, For More details, pls feel free to contact to us on sale.