What are the advantages of laser welding power battery

As the main power battery, power battery is widely used in industry, life and other aspects. As we all know, as a key step in the production, design and application of new energy vehicle power battery systems, PACK is the core link connecting upstream battery production and downstream vehicle application. The PACK grouping process level of power battery packs is directly related to the power of electric vehicles. performance and safety features. So what are the advantages of laser welding in the application of power batteries?

Stability, low loss of welding material

The power battery has many laser welding parts, the process is difficult, and the welding process is more demanding. Through efficient and precise laser welding, the safety, reliability and service life of automotive power batteries can be greatly improved. The advantages of laser welding are that the welding material loss is small, the deformation of the welded workpiece is small, the equipment performance is stable and easy to operate, and the welding quality and automation are high. Its technological advantages are unmatched by other welding methods.

More efficient

Laser welding equipment can be basically divided into three types: desktop equipment, fully automatic closed-loop workstation and fully automatic assembly line.

Desktop equipment, basically a single-machine semi-automatic console, is used in the testing of initial pilot products and small batch production.

Fully automatic closed-loop workstation, mostly in the mode of combining two swords, laser host plus closed-loop control workbench, each workbench is generally equipped with multi-station fixture tooling, suitable for various types of power battery laser welding and battery pack PACK welding Single-stage fully automatic system of the process.

Fully automatic production line, an upgraded version of fully automatic closed-loop workstation, connects multiple workstations to form a complete intelligent automatic production line for cell welding or battery pack PACK welding.

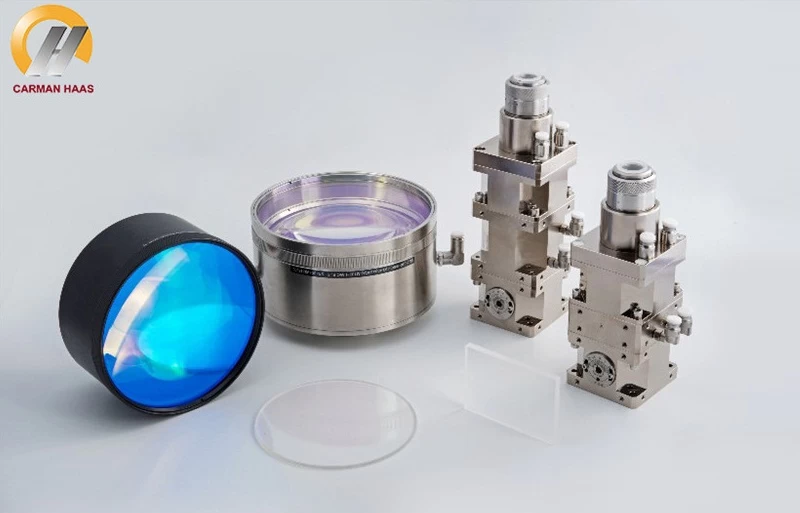

Power battery laser cutting lens

Safer

The safety of power batteries is widely debated. The battery itself should not bulge, leak, rupture, fire, smoke or explode. Once the thermal runaway of the battery cell occurs, electrolyte leakage, fire and combustion may occur. The use of the battery explosion-proof safety valve in the lithium battery can effectively prevent the battery from exploding when the battery is thermally out of control, thus ensuring the safety of the battery.